Glass Fiber Textile Micropore Insulation Board - Heat Insulation Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Micropore Insulation Board ,Heat Insulation materials

| Type: | Other Heat Insulation Materials | Place of Origin: | (Mainland) | Brand Name: | |

| Model Number: | 1000 | coating: | alumina foil/glass fiber cloth | Dimension: | 1000*500*10/20/30/40/50 mm |

| Density: | 300kg/m3 |

Packaging & Delivery

| Packaging Details: | wooden box |

| Delivery Detail: | 15 days after receipt of pre-payment |

Specifications

With heat-resistant inorganic fiber as reinforcing material combined with binders, NATI nanometer micro-heat conduction material

Introduction for Micropore Insulation Board ,Heat Insulation materials

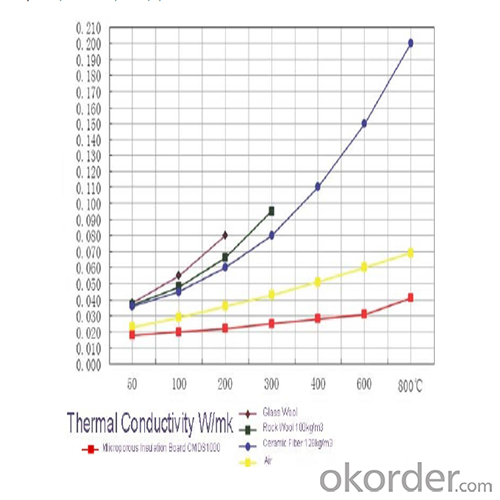

With heat-resistant inorganic fiber as reinforcing material combined with binders, NATI nanometer micro-heat conduction material is made of nanometer porous high-temperature resistant material and functional material with heat shield function through the combination of nanotechnology and special techniques. It has extremely low thermal conductivity that is just as one forth to one tenth that of ceramic fibre thermal insulation material.

Characteristics:

*High temperature resistance.

*Low thermal conductivity.

*Eco-friendliness and safety.

*Low thermal storage.

*Long service life.

Typical Application:

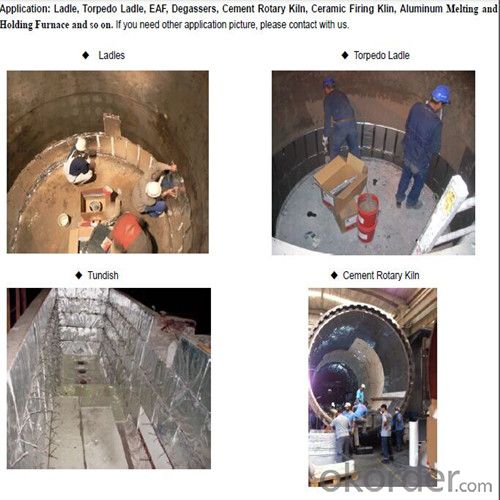

*It is widely used in various industries such as steel, petrochemical

Chemical & Physical Data:

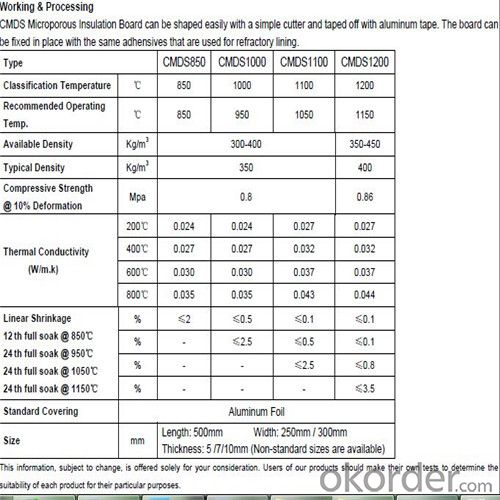

Type | 1000 NATI Micropore Board |

Bulk Density (kg/m3) | 300-350 |

Pressure Strength (MPa) | 0.7 |

Permament Linear Shrinkage %(800℃×6 hour) | 3.5% |

Thermal Conductivity (W/m.K) | 0.020(at 100 ℃) |

0.025(at 200 ℃) | |

0.028(at 400 ℃) | |

0.032(at 600 ℃) | |

0.037(at 800 ℃) |

Standard Dimension:

1000(900)×600(500)×5-20mm

We can also manufacture the special dimensions as customers need.

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C,Western Union,Moneygram,Paypal are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Thanks for your coming in,if there is any question,I will be glad to help you.

- Q: How do glass fiber textiles resist shrinking?

- Due to its unique material properties, glass fiber textiles are resistant to shrinking. The process of making glass fibers involves rapidly cooling molten glass, resulting in a durable and strong fiber structure. Unlike natural fibers like cotton or wool, glass fibers lack the ability to absorb moisture, a major cause of shrinking in textiles. Moreover, glass fibers exhibit a low coefficient of thermal expansion, meaning they do not significantly expand or contract when exposed to temperature changes. This stability prevents the fibers from shrinking or warping under heat. Additionally, glass fibers have a high melting point, rendering them heat damage resistant. Additionally, glass fiber textiles often undergo treatment with special finishes or coatings that provide extra protection against shrinking. These finishes effectively seal the fibers and prevent moisture absorption, further enhancing the textiles' resistance to shrinking. In conclusion, the combination of glass fiber's inherent properties and the application of finishes or coatings make glass fiber textiles highly resistant to shrinking. This allows them to maintain their shape and size even in various environmental conditions.

- Q: Can glass fiber textile be used in oil and gas pipelines?

- Yes, glass fiber textile can be used in oil and gas pipelines. Glass fiber textiles are known for their high strength, corrosion resistance, and ability to withstand high temperatures, making them suitable for use in demanding environments such as oil and gas pipelines. They provide excellent insulation and are capable of withstanding the harsh conditions typically encountered in the oil and gas industry.

- Q: How do glass fiber textiles affect breathability?

- Glass fiber textiles can significantly reduce breathability due to their dense and non-porous nature. Unlike natural fibers, glass fibers do not allow air to easily pass through, thus restricting airflow and ventilation. This can result in reduced breathability and increased heat and moisture buildup, making the fabric less comfortable to wear in terms of breathability.

- Q: Who has a Chinese English translation about glass fiber?. About WORD3 pages will do

- Glass is a substance known for its brittleness. Interestingly, once the glass is heated after being drawn into a much thinner than a human hair fiber glass, it seems completely forget their own nature, be like synthetic fiber as soft and tough, even more than the stainless steel wire of the same thickness!So, what's the use of glass fiber?

- Q: What are the limitations of glass fiber textiles?

- Before using glass fiber textiles, it is important to take into account their various limitations. Firstly, these textiles are quite fragile and can easily break when subjected to excessive stress or impact. This makes them unsuitable for situations where flexibility and resistance to breakage are essential. Secondly, glass fiber textiles have a relatively low tolerance for heat. They can melt or distort when exposed to high temperatures, which restricts their use in environments with extreme heat conditions. Moreover, these textiles are not fire-resistant and may contribute to the spread of flames. Additionally, glass fiber textiles have a tendency to absorb moisture, which can negatively affect their mechanical properties. This restricts their use in outdoor applications or environments with high levels of humidity, where moisture damage can compromise their integrity. Furthermore, working with glass fiber textiles can be challenging due to their sharp and abrasive nature. Handling them without proper protective equipment can cause skin irritation or respiratory problems. Therefore, it is necessary to take appropriate safety precautions when working with these textiles. Lastly, glass fiber textiles are generally more expensive compared to other materials such as cotton or polyester. This cost factor can be a limitation in situations where cost-effectiveness is crucial. In conclusion, while glass fiber textiles offer advantages such as high strength and chemical resistance, it is important to carefully consider their limitations in terms of brittleness, heat resistance, moisture absorption, handling challenges, and cost in order to make informed decisions about their usage.

- Q: Are glass fiber textiles resistant to moisture or water?

- Glass fiber textiles possess resistance against moisture and water. They are composed of inorganic substances like silica, which prevents the absorption of water or moisture. This innate moisture resistance renders glass fiber textiles exceptionally suitable for areas prone to water or high humidity, such as bathrooms, kitchens, or outdoor settings. Furthermore, glass fiber textiles retain their integrity and durability in wet conditions without rotting or degrading, ensuring their longevity.

- Q: Can glass fiber textiles be felted?

- No, glass fiber textiles cannot be felted. Felt is a fabric made by matting, condensing, and pressing fibers together. It is typically made from animal fibers such as wool, which have natural scales that interlock when subjected to heat, moisture, and pressure. Glass fibers, on the other hand, are made from molten glass that is drawn into thin strands. These fibers do not have the same properties as animal fibers and therefore cannot be felted.

- Q: Can glass fiber textiles be used in the production of furniture?

- Yes, glass fiber textiles can be used in the production of furniture. Glass fiber textiles are strong, durable, and have excellent resistance to heat and chemicals. They can be used as upholstery or reinforcement material in furniture, providing added strength and stability to the product. Additionally, glass fiber textiles can also be used as a decorative element, adding a unique and modern touch to furniture designs.

- Q: Can glass fiber textiles be used in the aerospace industry?

- Yes, glass fiber textiles can be used in the aerospace industry. Glass fiber textiles, also known as fiberglass textiles, are lightweight, strong, and have high tensile strength, making them ideal for various aerospace applications. They are commonly used in the construction of aircraft parts, such as fuselages, wings, and empennages. One of the main advantages of glass fiber textiles is their excellent resistance to corrosion, which is crucial in the aerospace industry due to the harsh environmental conditions that aircraft are exposed to. Additionally, glass fiber textiles have excellent thermal insulation properties, which can help maintain the desired temperature inside the aircraft. Furthermore, glass fiber textiles can be molded into complex shapes, allowing for the production of customized components with high precision. This flexibility makes them suitable for various aircraft designs and enables the optimization of weight and performance. Moreover, glass fiber textiles have a relatively low cost compared to other materials used in the aerospace industry, such as carbon fiber composites. This cost-effectiveness makes them an attractive option for manufacturers, especially for non-critical components that do not require the highest strength-to-weight ratio. However, it is important to note that glass fiber textiles may not be suitable for all aerospace applications. In cases where extreme strength and stiffness are required, materials such as carbon fiber composites may be preferred. Nonetheless, glass fiber textiles offer a reliable and cost-effective solution for many aerospace applications, making them a widely used material in the industry.

- Q: Can glass fiber textile be used in bulletproof vests?

- Yes, glass fiber textiles can be used in bulletproof vests. Glass fiber fabrics can provide high strength and excellent resistance to penetration, making them suitable for use in bulletproof vests to protect against ballistic threats.

Send your message to us

Glass Fiber Textile Micropore Insulation Board - Heat Insulation Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords