Microporous Insulation Board for Fuel Cell and Microporous Thermal

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Working & Processing of Microporous Insulation Board

CMAX Microporous Insulation Board can be shaped easily with a simple cutter and taped off with aluminum tape. The microporous insulation board can be fixed in place with the same adhesives that are used for refractory lining.

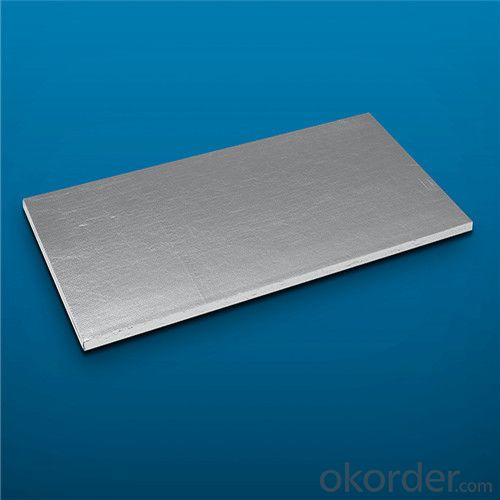

General Information of Microporous Insulation Board

CMAX Microporous Insulation Board is specially designed for steel industry & metallurgy with very good thermal and mechanical properties. The formulation is an opacified blend of filament reinforced pyrogenic silica. The coverings is water repellent to assure the stability of the microporous board when moisture may occur due to castables, mortar etc.

Application of Microporous Insulation Board

Ladle

Torpedo Ladle

EAF

Degassers

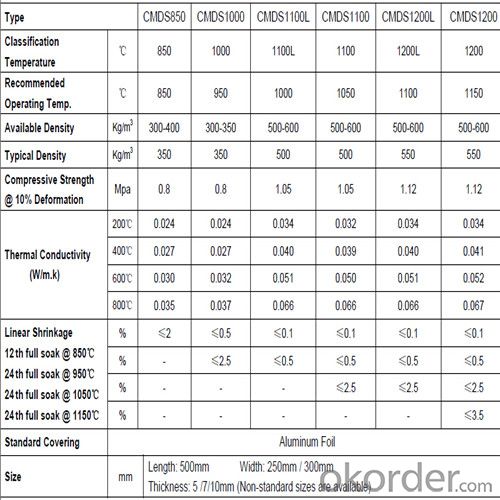

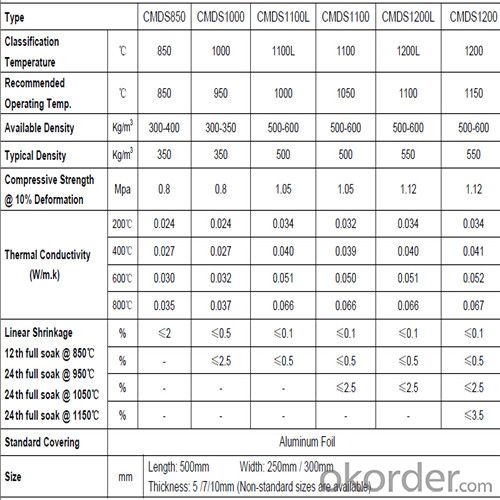

Technical Data of Microporous Insulation Board

Image of Microporous Insulation Board

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Send your message to us

Microporous Insulation Board for Fuel Cell and Microporous Thermal

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords