Raw Materials for Refractory Metal Bonded Unburned Sliding Gate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

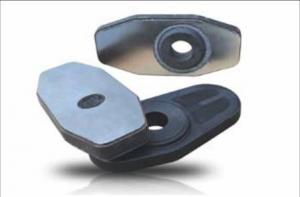

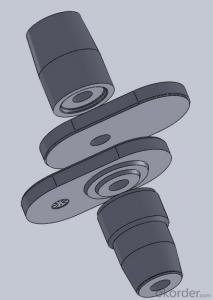

Metal bonded unburned sliding gate

This kind of sliding gate importing special metallic additives, which generate the phase has excellent high temperature performance behavior in the process of using. The using effect on the large and medium-sized steel ladle and the tundish is good.

Metal bonded unburned sliding gate has the following characteristics:

Sliding gate do not have carbon, there will be no carbon oxidation cause massive sgraffito surface, which is more suitable for low-carbon steel, ultra-low carbon steel and the casting of Stainless steel. Magnesia bonded sliding gate is particularly well suited for high calcium treatment steel, killed steel, rimming steel, etc. For special steel there will be no groove at the sliding zone.

Good thermal shock stability and cracks in using is small, guarantee the security of casting steel.

The use of the product performance is stable and the production cycle is short.

- Q: The fire prevention board line is made of what material?

- (1) if it's real wood floor, the line should be made of wood. The ready-made wooden line, walnuts, price range depends on the texture width. The common width is 100 mm. One linear meter is around $17 - $30. Paulownia is cheaper with one linear meter more than 10 yuan. When it is composite wood floor, high-density plate modelling line can be used. The price is commonly between 40 to 80 yuan (2400 x 1200 mm), which depends on the thickness and density and also the factory. There are also imitated wooden aluminium line. (3) if it's the marble ground, you would better use marble line, which is 200 yuan one square meter. It's price is also unequal. The imitated stone is also available. There are a lot of kicking decoration materials and it depends on how you use it. That is to say crural line should be coordinate with the ground. It means that it sjould not only to be beautiful but also to be practical. It would be better if it is relatively cheap as well.

- Q: How long is the duration of fire resistance of autoclaved flyash-lime bricks?

- The compressive strength of the autoclaved flyash-lime bricks is generally higher, which can reach 20MPa or 15MPa, at least 10MPa, and it can withstand the 15 freeze-thaw cycles. Besides,fly ash brick is a kind of potential active hydraulic material. In the humid environment, it can continue to produce hydration reaction and make the internal structure of the brick is more dense, which is conducive to improvement of the strength. It is found in experiments and many investigations that sample some carbide which is used for foundation, plinth and drains, after one or twenty years of freezing thawing and wetting drying, some bricks have been completely carbonized, but strength is not reduced, increased instead. This is one of the merit of autoclaved flyash-lime bricks.

- Q: Who can tell me what is neutral refractory?

- Refractories mainly refer to aluminum oxide, chromium oxide and carbon as the main component of refractory materials, such as corundum brick, high alumina brick, and carbon brick. Its characteristic goes to the resistance to both acidic and basic slag. Basic refractories mainly refer to the refractory materials whose mian components are magnesium oxide and calcium oxide, including magnesia bricks, magnesia-alumina bricks, magnesia chrome bricks, dolomite bricks, etc. Basic refractory is good at resisting basic slag erosion.

- Q: Development trend of refractories

- The foundation of China's refractories industry is still relatively weak, the utilization level of refractory material resources is low, the quality of refractory materials is not high, excess production capacity of ordinary products, the key products of some high-quality high technology content can be produced, but the quality is not stable, and the service life of refractory material consumption compared with foreign advanced level, there is a considerable gap. Therefore, the new trend of tracking foreign refractories science and technology development, carry out and supporting the development and application of advanced and basic theory research, to promote technological innovation of refractory materials, optimizing product structure, industrial structure adjustment, implementation of the strategy of sustainable development, it is very necessary.

- Q: What is the criterion of entry of refractory clay industry?

- Chemical composition of refractory clay is one of the important factors affecting its quality. Al2O3 is the beneficial part of refractory clay, and it mainly exists in aluminum hydroxide minerals (diaspore, boehmite, gibbsite), and it also exists in aluminosilicate minerals (kaolinite, illite montmorillonite, etc.). In general, the content of Al2O3 in soft and semi-soft clay is 30% to 45%, the hard clay is 35% to 50%, and high alumina clay 55% to 70%. Fe2O3 mainly exists in hematite, magnetite, goethite and siderite, and is the main harmful component of refractory clay. There is no evident law on the content of Fe2O3. The content in high alumina clay is 0.5% to 2.2%, hard clay is 0.5% to 2.5%, and the soft clay is generally 1.0% to 2.5%. K2O and Na2O are harmful impurities in refractory clay, which mainly exist in illite and mica and other minerals, and the content varies greatly. CaO and MgO, etc., although they are harmful impurities, but the content is generally small.

- Q: What's the frequently used refractory material?

- What's the frequently used refractory material in the market? It is usually classified into four categories: Common Refractory: silica?brick, semi-silica brick, refractory fireclay block, high alumina refractory brick, magnesia brick, etc. Unshaped Refractory: repairing?mass, ramming refractory, refractory castable, plastic refractory, refractory mortar, gun-mix refractory, sling refractory, refractory coating, lightweight refractory?castables, stemming, etc. Special Refractory: AZS brick, corundum brick, direct-bonded?magnesia-chrome?bricks, carborundum brick, silicon nitride bonded silicon carbide brick, nonoxide refractories like nitride, silicide, sulfide, boride and carbide, and oxide refractories like calcium oxide, chromium hemitrioxide, alumina, magnesium oxide and beryllia, etc. Fireclay Insulating Refractory: diatomite product, asbestos product, insulation?board, etc.

- Q: What are the new types of refractories? What are the characteristics? Their applications and developments?

- AZS refractories are often used brick, corundum brick, magnesia chrome brick, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, alumina, Magnesium Oxide, beryllium and other refractory materials.Often used insulation refractories are diatomite products, asbestos products, insulation panels and so on.Unshaped refractory materials commonly used are fettling, refractory ramming material, refractory castable, refractory plastic material, refractory clay, refractory gunning, refractory cast material, fireproof coating, lightweight castable, mud etc..

- Q: What are first rate fire resistant window materials?

- class A window not less than 1.2 hours, class B window not less than 0.9 hours, Class C window not less than 0.6 hours. technical requirments: 1, materials and accessories (1) the window frame is made with a certain strength sufficient to safeguard the integrity and stability of the steel frame or wooden frame. (2) steel frame and mound layer can choose the galvanized steel plate or stainless steel plate. Its selection standards is in line with GB12955 "Steel Fireproof Door General Technical Condition" provisions of Article 5.1. (3) wood frame and mound layer material selected from the standard should be consistent with GB14101 "General Technical Conditions of Wooden Fireproof Door" in the provisions of Article 5.1.1. (4 ) steel, wood frame the inside filler material should be incombustible material. (5) fireproofing glass can be used without affecting the fire windows fire resistance test approved product. light transmittance of glass should not less than 75% of commom sheet glass which is the same number of layers. ( 6) a sealing material between the frame and the fire-resistant glass flame retardant materials should be used, which can play the role of fireproofing and smoke insulation in case of fire (7) hardware fitting should be tested as approved supporting product

- Q: What are grades of refractory materials?

- Refractories have lots of varieties which all have different purposes.1 divided according to the level of refractoriness: ordinary refractory materials: 1580 ℃ to 1770 ℃, advanced refractories: 1770 ℃ to 2000 ℃ and super refractories: above 2000 ℃ 2, divided in accordance with shapes and sizes : Standard ones: 230mm × 113mm × 65mm, no more than four ruler.

- Q: Classification of porosities in refractories and their effects on properties

- The first two types of stomata are commonly examined, known as apparent porosity.

Send your message to us

Raw Materials for Refractory Metal Bonded Unburned Sliding Gate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords