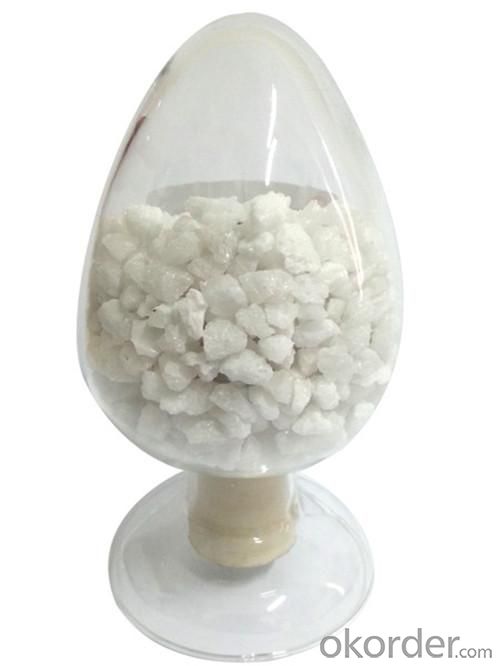

White Fused Alumina - Raw Materials for Refractory

- Loading Port:

- Xingang,Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 20000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of White Fused Alumina:

Place of Origin: China mainland

Material:High purity bauxite

Usage:Refractory,sand plasting,abrasives,etc.

Abrasive Grain Sizes: All size accordig to customers' requirements .

Specifications of White Fused Alumina:

|

Al2O3 |

Fe2O3 |

SI020 |

Na2O |

B.D |

|

99.20% MIN |

0.10% MAX |

0.20% MAX |

0.30% MAX |

3.7G/CM3 MIN |

Size: 0-1mm, 1-3mm, 3-5mm.... such phase sand

0-10mm; 0-30mm................such block sand

220mesh, 325mesh............such fine powder

Packaging & Delivery of White Fused Alumina:

Packaging details:1mt big bag or according to customers’ requirements

Delivery:7-15 work days after the order is confirmed

Applications of White Fused Alumina:

-Blast-cleaning

-Roughening

-Grinding, lapping and polishing media

-Reusable abrasive

-Ceramic grinding wheels and grinding media

-Wear-resistant and refractory products

Competitive Advantage:

High Purity & Good Quality.

Good Hardness & High Heat-resistance.

Competitive Price & Reputable Supplier.

Timely delivery & service

Good company reputation

- Q: What are the materials of insulation firebricks?

- The raw materials of firebricks, firebricks have various raw materials, and the composition of which can be divided into six categories: soil, stone, sand, mineral, powder and others. One of the raw materials, soil: bauxite, kaoline, clay, diatomite Another raw material, stone: fluorite, kyanite, andalusite, forsterite, vermiculite, mullite, pyrophyllite, chlorite, dolomite, sillimanite, magnesia-alumina spinel, and silica Another raw material, sand: clay sand, zircon sand, quartz sand, and magnesite Another raw materials, mineral: chromium mineral Another raw material, powder: aluminum powder, micro-silica powder, and silicon powder Another raw materials, others: asphalt, graphite, phenolic resin, perlite, cenosphere, sialon, corundum, silicon sulfate, silicon carbide, sodium silicate, silica sol, boron carbide, calcium aluminate cement, nitride material, haydite, aluminum oxide, alumina sol and zirconia, etc.

- Q: What are the electrical fire protection materials?

- Flame retardant organic resin: They can be classied into PVC, vinyl chloride, chlorinated rubber, epoxy resin emulsion, epoxy resin, phenolic resin, etc.. Fire retardant additive: Phosphorus and halogens, nitrogen organic compounds (chlorinated paraffin, tributyl phosphate (TBP) and polybrominated diphenyl ethers) and boron (boric acid, zinc borate, boric acid aluminum), antimony, aluminum, zirconium inorganic compounds.

- Q: Can anyone tell me the requirements of the refractory masonry??

- Refractory materials actually have two functions. The first one is to improve the refractoriness and the second one is to improve the body plasticity of refractory materials.The higher the aluminum content is, the better refractory it will be. Of course, the content of aluminum in refractory materials can not be impoved only by using kaolin. Such raw materials that contain more aluminum as bauxite chamotte should be used as framework.So the content of aluminum in kaolin does not need to be too high and more than 38% of aluminum is enough. However, the viscosity should be taken into account. It will be better if the viscosity is better as the extra bentonite do not need to be added.The refractoriness that is is above 1400 degree is enough.

- Q: What is the principal part of silicious refractory material

- blast furnace hot blast stove and ceramic tunnel kiln vault, etc., the softening temperature under a fixed load is high (1690-1710 degree), glass melting furnace, lightweight silica bricks and generally the silicon?dioxide is greater than 93% and used above the 600 degree. I had undertaken to complete the 50,000 tons over two advanced silica brick production line design. It is a typical acidic refractory. At present, it is mainly used to coke oven which the masonry operating temperature is higher than 600 degree, with good acid resistance of slag erosion, including silica?brick, good thermal conductivity, high thermal vibration stability, product with fused quartz, close to its refractoriness silicious refractory SiO2 which is as the main component of refractory products.

- Q: How long is the fire resistant limit for ultra thin fire retardant coating?

- The fire resistant limit of ultra-thin fire retardant coating is 1.5 hours, generally fire resisting time for thin fire retardant coatings does not exceed 1.5 hours. If the time exceeds 1.5 hours, thick fire resistive coating should be uesd. There is no detailed stipulation for ultra-thin fire retardant coating, and the thickness of the inside is the fire resistance limit shall reach certain time(at least). If fire resistance limit is 2.5 hours, the thickness shall be 4.9mm. If the fire resistance limit is 2 hours, the thickness is 3.5mm. If fire resistance limit is 1.5 hour, the thickness should be 1.75mm.

- Q: Who knows what is the external wall thermal insulation materials for level A fireproofing?

- external wall thermal insulation materials level A fireproofing: Incombustible building material is a material that does not occur any burning. Class A1: Monomer inorganic non-combustible. Noncombustible means no open fire. Class A2: Non-flammable organic compound is namely composite materials and non-flammable, the amount of smoke must be qualified. Class B1: nonflammable building material: non-flame material has good flame resistance. It is difficult to fire under the condition of open fire in the air or high temperature, and it is not easy to quickly spread, and when the combustion?source is removed, the combustion will stop immediately. Class B2: combustible?building?materials: flame material has a good flame resistance. In case of fire in the air or at high temperature, it will immediately burst into flames, and easily lead to the spread of fire, such as wooden column, timber roof truss, timber beam and wooden stairs.

- Q: What's the classification of refractory material?

- Magnesium aluminum is complex and mainly seeing what classification standard is like according to the appearance shape can be divided into two categories, setting and not setting according to the acid alkali can be divided into acidic, magnesia, high aluminum, ramming expected, spinel, spray coating, plastic, just the quality of the jade, daub material according to the chemical composition is divided into, such as clay, neutral and alkaline according to the operation mode can be divided into different castable, magnesium, calcium, magnesium chrome

- Q: Who knows the external wall thermal insulation materials fire rating requirements?

- 1. The thermal insulation material of level A combustion performance: Rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite, etc. 2. combustion performance is level B1 insulation materials: Extruded polystyrene board (XPS) after special treatment / Special treatment of polyurethane (PU), phenolic aldehyde and gelatine powder polyphenyl granule 3, combustion performance is level B2 insulation material: Molding polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc. See the 2009 edition construction technical measures 4.3.6 Level A insulation material is only for fireproofing, but its thermal insulation performance is not better than organic XPS \\ EPS and other materials. I feel the best insulation materials should be modified phenolic board, which can keep insulation and fireproofing, but the unit price is very expensive. Insulation materials in the domestic market have some disadvantages, it is better to considere the materials within the acceptable range in the building needs.

- Q: Does refractory belong to metallurgical auxiliary materials?

- Refractory is widely used in industrial circle, such as metallurgy, chemical industry, petroleum, mechanical manufacturing, silicate and power, and its coonsumption is the maximum in metallurgy, accounting for 50% to 60% in total output. In order to improve slag-corrosion resistance of furnace lining, usually choose carbon-containing refractory. Refractory of various furnace lining are respectively: For the body, it is clay brick; as for the lower part, bosh and middle, it is SiC brick; for furnace bottom, it is carbon brick. Lattice brick is an important refractory product used in air heating furnace and regenerative chamber. Refractory is widely used in metallurgy. In order to improve slag-corrosion resistance of lining. Central line in tuyere and hearth are high-alumina brick. Refractory consumption is the maximum in metallurgy, accounting for 50% to 60% in total output. For the bosh and middle, it is SiC brick. In order to improve its thermal storage capacity: The furnace stack is clay brick. It is defined as refractory where the physical and chemical properties allows its use in high temperature environments; The lower furnace body

- Q: what is steel fire door made of ?

- 1. fire resistance steel door has steel made door frames, door leaf framework and door panels. if the door leaf is filled with nontoxic fire insulation material, added with fireproof hardware accessories, which consists of a door that is fire resistance. This is a steel door.

1. Manufacturer Overview

| Location | Tianjin,China |

| Year Established | 2006 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East;Western Europe;Japan;North America |

| Company Certifications | The Authentication certificate of Quality Management system |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 300,00 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

White Fused Alumina - Raw Materials for Refractory

- Loading Port:

- Xingang,Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 20000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords