Raw Materials for Refractory Fiber Rope

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

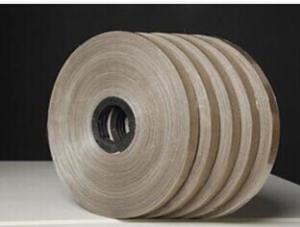

Ceramic Fiber Rope

Good Thermal Insulation

Density:500 kg/m3

round ,square braided or twisted

Customized prorduction is ok

LUYANGWOOL Ceramic fiber rope is produced by processing refractory ceramic fiber. Various textiles can be produced by ceramic fiber. LUYANG ceramic fiber ropes are woven or braided from yarn consisting of refractory ceramic fiber with approx 20% organic fibre. Alloy wire inserts are available for obtaining maximum strength ar elevated temperatures. Glas filament inserts are used in applications where electrical resistance is required. LUYANGWOOL ceramic fiber rope can be used up to 1260C.

Application

Gasket and wrapping material.

Cable and wire insulation.

Welding curtains and blankets.

Furnace curtains and heat zone separators

Expansion joint

Fuel line insulation

Welding blankets

High temperature seals and packing in furnace and heaters cord

thermal insulation pipe wrap

furnace door seals jointings.

Standard Specification

Sevice temperature: 450-1000C

Production type: round braided,square braided,twisted

Type: fiberglass reinforced and stainless steel reinforced

Density: 500 kg/m3

Size:

50000/10000x25/50mm ( round braided)

10000x(50x50)mm (square braided)

50000~20000x6~50mm( twisted rope)

Moisture content:≤ 2%

Organic content:≤ 15 %

Description GF-R-Rope SS-R-Rope GF-T-Rope SS-R-Rope

Density (kg/m3) 500 500 500 500

Classification Temperature ( 0C ) 1260

Maximum Operating Temperature ( 0C ) 500-600 1000 500-600 1000

Water Content ( % ) ≤1

Organic matter content (%) ≤15

Reinforced material Glass fiber Stainless steel Glass fiber Stainless steel

- Q: what kind of refractories is used to make the industrial silicon furnace mouth long life?

- Fused zirconia corundum brick, the smelter of the glassworks is used this kind of lining, and you can contact by private letter.

- Q: Who knows about the fire endurance of A grade fireproofing glass doors?

- The fire endurance of grade A fire resistance rolling shutter doors should be no less than three hours. Fire doors can be divided into A, B and C grades according to their fire endurance which should be no less than 1.20 h, 0.90 h and 0.60h respectively. Places where are difficult to set fire-proof bulkheads can use fire resisting shutters as partitions of fire?compartments. The fire endurance of fire resisting shutters that include unexposed surface temperature rise as judging condition should be no less than 3 h. Fire resisting shutters that exclude unexposed surface temperature rise as judging condition should set up independent protection of closed automatic water spray system on both sides of shutters, and the duration of water spray system should be no less than 3.0 h.

- Q: I wanna ask you, which level is b1 fireproof and thermal inuslation matertial ??

- What you said is the pixel! Only that has b1b2. Level b1 is the fireproofing level b1, because the particle does not belong to the fireproofing material. Only can fire?retardant. The wholesale of all kinds of thermal insulation material and construction need to look at the name.

- Q: Manganese steel belongs to refractories

- Material wear and other harsh working conditions, extrusion, there will be work-hardening phenomenon rapidly on the surface. The most important feature of manganese steel is that it is not refractory under a strong impact, and under extrusion conditions, part of it will be fractured. The main form of damage is wear and consumption: It is a kind of inorganic non-metallic material whose refractoriness is not lower than 1580 ℃, mainly used to endure impact. Manganese steel is a kind of high strength steel, which is free of deformation, so that it can remain austenite good toughness and ductility at heart while keeping good wear resistance at the same time on hardened layer. Refractories are

- Q: What are the differences between intensive refractory busway and other busways?

- Compact busway is named according to its structure, and fire-resistant busway is named after its uses. Compact busway especially refers to busway which is closely laminated between phases and between phase and shell, and use thin insulating material to achieve the insulation result. Suitable for power supply system of alternating current three-phase four-wire, three-phase five-wire system, frequency of 50 ~ 60Hz, rated voltage up to 690V, rated operational current of 250 ~ 5000A, as auxiliary equipment for mining, enterprises and high-rise buildings, and especially suitable for the transformation of workshop and old enterprises. Fire-resistant busway is composed of shell coated with fire retardant paint, bus line wrapped with fire-resistant mica tape and bracket made by refractory insulating material. Bracket has a plurality of grooves where inbedding the bus line and fixed it. There is a busway connecting box at one end of the busway and there is a bus line splitter box in the busway. Fire-resistant busway has excellent insulation properties, which can not only be used continuously in a normal environment, but also can be used in the fire environment continuously for more than one hour, suitable for high-rise buildings and important facilities.

- Q: How to measure the influence of high-temperature performance of the products refractory in the formation of the liquid phase.

- Generally how can do high-temperature performance to measure how much liquid may affect hot bending strength rul refractoriness levels of high temperature creep?

- Q: what needs to be noted when choosing and using blast furnace fireproof materials?

- Hello,: three parts of the blast furnace lining in general are easily corroded. The first one is furnace bosh,second is the middle part of the furnace, The third is lower part of the furnace stack. if These parts are damaged, then we need an overhaul. Bosh, because damage to the middle part of the furnace and the furnace bosh are generally due to alkali metal and fusant erosion. the main reason for the lower furnace part damage is molten iron, slag. In view of this situation, mullite bricks, corundum bricks, silicon carbide bricks are used for reparation. make repairments as soon as possible if any problems occur in case of incidents.

- Q: Firing high temperature kiln of refractory and internal temperature being as high as 1600 ℃, metal heat exchanger can't use, how to do?

- Directly using silicon molybdenum kiln, the temperature is better. Now using the electricity is cheaper than the price of other fuels.

- Q: What is the quote of fireproof and soundproof materials used in KTV?

- acoustic material, aluminum foil glass wool, sound-deadening material, glass wool, cinema / KTV dedicated glass wool: The classification of glass fiber products: The category of glass wool felts: The level of insulation cotton: A-level brands: New applications: The origin of GB/T13350-2008: The coefficient of thermal conductivity(room temperature): 0.035 bending at low temperature≤: 0.02 elongation at break: ≤80kPa flexure strength: ≤120kpa Compressive strength: ≤150kpa application temperature: 700 Core material: The shape of glass wool: Fibrous shape: Coil Specifications: Complete quote is 23 Yuan per cubic meter. glass wool board, KTV sound insulation core material: The shape of glass wool: The level of rectangular glass wool: A-level non-combustible brands: Kunnai material: The origin of glass fiber: Guangzhou, Shijiazhuang, Wuhan, the quote there is 8.8 Yuan per cubic meter.

- Q: On the problem of making refractory materials

- Refractories mainly depend on their high melting point characteristics. The refractory market is mainly Magnesium Oxide material.

Send your message to us

Raw Materials for Refractory Fiber Rope

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords