Melt Extract Stainless Steel Fiber - Straight Type Steel Fiber from CNBM International

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Shandong, China (Mainland)

Brand Name: CNBM

Model Number: LONGSTONE

Material: Stainless Steel

Specifications

Specifications

Produces shear type, steel wire type, cut type, stainless type, and micro wire type steel fiber. It is used for concret.

SPECIFICATION

TYPE | SIZE | tensile strength |

ENDHOOKED STEEL FIBER | 0.5×0.5×30 mm | 850Mpa min |

0.6×0.7×35 mm | 850Mpa min | |

0.5×0.5×30 mm | 1000MPA min | |

0.6×35 mm | 1000MPA min | |

0.9×60 mm | 1000MPA min | |

CORRUGATED STEEL FIBER | 0.25×0.25×10 mm | 380Mpa min |

0.25×0.25×14 mm | 380Mpa min | |

0.5×0.7×32 mm | 380MPA min |

OTHER SPECIFICATIONS CAN BE DISCUSSED AS PER BUYER’S OPTION

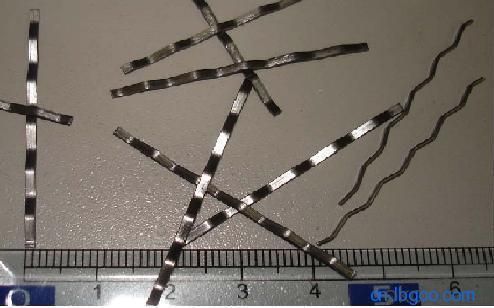

Picture

Steel fiber straight type

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: How does melt extract stainless steel fiber improve the impact resistance of bridge decks?

- Melt extract stainless steel fiber is a promising material that can significantly improve the impact resistance of bridge decks. This fiber is manufactured by melting stainless steel and then extracting it into fibers of various lengths and diameters. These fibers are then mixed into the concrete matrix during the construction of bridge decks. The addition of melt extract stainless steel fiber to bridge decks brings several benefits that enhance their impact resistance. Firstly, the fibers act as reinforcement within the concrete, creating a three-dimensional network that increases the tensile strength and overall durability of the structure. This reinforcement effectively distributes the load and impact forces, preventing cracks and fractures from propagating and compromising the integrity of the bridge deck. Moreover, the unique properties of stainless steel, such as its high strength, corrosion resistance, and ductility, make it an ideal material for improving the impact resistance of bridge decks. When subjected to impact or dynamic loading, the stainless steel fibers absorb energy and dissipate it throughout the concrete matrix, reducing the stress concentration and minimizing the risk of damage. This energy absorption mechanism helps bridge decks withstand heavy traffic, seismic events, and other external impacts. Additionally, melt extract stainless steel fibers enhance the crack resistance of bridge decks. The presence of these fibers inhibits crack formation and propagation, as they act as micro-reinforcements that bridge small cracks and prevent them from expanding. This crack bridging effect not only improves the overall durability of the bridge deck but also minimizes maintenance needs and extends the service life of the structure. In conclusion, melt extract stainless steel fiber is a valuable addition to bridge deck construction, as it significantly improves impact resistance. By reinforcing the concrete matrix, absorbing and dissipating energy, and enhancing crack resistance, this material ensures the longevity and structural integrity of bridge decks, making them more resilient to various types of impacts.

- Q: How does melt extract stainless steel fiber improve the impact resistance of airport pavements?

- The impact resistance of airport pavements can be greatly enhanced with the use of melt extract stainless steel fiber. This material is commonly employed as reinforcement in concrete to enhance its mechanical properties and increase its durability. By incorporating melt extract stainless steel fiber into airport pavements, their capacity to withstand impact forces is significantly improved. When aircraft land or take off, they exert immense pressure and impact on the pavement surface. Without adequate reinforcement, this can result in cracking, spalling, and other forms of damage. The stainless steel fiber functions as reinforcement by dispersing the stress caused by impact forces over a wider area. This helps to distribute the load and prevent concentrated pressure points, which are more susceptible to damage. Consequently, the airport pavements become more resistant to cracking and other forms of structural failure. Additionally, melt extract stainless steel fiber also enhances the overall toughness of the pavement. It effectively impedes the propagation of cracks, limiting their length and depth. This significantly reduces the risk of extensive damage and prolongs the lifespan of the pavement. Moreover, the stainless steel fiber provides increased resistance to fatigue. Airport pavements undergo repetitive loading and unloading cycles that can lead to fatigue failure over time. The inclusion of stainless steel fiber enhances the pavement's ability to withstand these cyclic loads, diminishing the likelihood of fatigue cracks and enhancing its overall resilience. In conclusion, melt extract stainless steel fiber is a valuable material for augmenting the impact resistance of airport pavements. Its incorporation into concrete reinforcement greatly enhances the pavement's ability to endure the pressure and impact forces generated by aircraft during landing and takeoff. This reinforcement disperses stress, impedes crack propagation, improves toughness, and enhances resistance to fatigue, ultimately resulting in a longer-lasting and more durable pavement.

- Q: What is the effect of melt extract stainless steel fiber on the modulus of porosity of concrete?

- By incorporating melt extract stainless steel fibers into the concrete mix, the modulus of porosity is significantly impacted. The inclusion of these stainless steel fibers helps decrease the overall porosity of the material, thanks to their exceptional attributes like high tensile strength and resistance to corrosion. The inclusion of melt extract stainless steel fibers serves to enhance the strength and durability of the concrete material by filling in gaps and reducing porosity. As a result, the concrete matrix becomes denser, leading to a decreased modulus of porosity. This reduction in porosity elevates the concrete's ability to resist water absorption, chemical attacks, and freeze-thaw cycles. Moreover, the stainless steel fibers also augment the concrete's ability to resist cracks and increase its ductility. Acting as reinforcement, these fibers offer additional strength and hinder the propagation of cracks. Consequently, the modulus of elasticity is improved, which measures the material's capacity to deform under stress and regain its original shape. All in all, the incorporation of melt extract stainless steel fibers into concrete yields positive outcomes for the modulus of porosity. It not only enhances the durability, strength, and crack resistance of the concrete but also makes it a preferable choice for a range of construction applications that demand high-performance and long-lasting concrete.

- Q: Can melt extract stainless steel fiber be used in water retaining structures?

- Yes, melt extract stainless steel fiber can be used in water retaining structures. Stainless steel fibers are corrosion-resistant and have high tensile strength, making them suitable for use in structures that are exposed to water or other corrosive environments. These fibers can enhance the durability and performance of water retaining structures by improving crack resistance, reducing permeability, and increasing flexural strength. Additionally, stainless steel fibers can help prevent the formation and propagation of cracks, which can be particularly beneficial in water retaining structures where maintaining water tightness is essential. Overall, the use of melt extract stainless steel fiber in water retaining structures can enhance their longevity and structural integrity.

- Q: What is the role of melt extract stainless steel fiber in refractory materials?

- The role of melt extract stainless steel fiber in refractory materials is to enhance the mechanical properties and improve the overall performance of the refractory material. The stainless steel fibers provide reinforcement and increase the tensile strength, thermal shock resistance, and resistance to cracking in the refractory material. They also help to improve the overall durability and longevity of the refractory material in high-temperature environments.

- Q: Can melt extract stainless steel fiber be used in earthquake-resistant concrete structures?

- Yes, melt extract stainless steel fiber can be used in earthquake-resistant concrete structures. Stainless steel fibers are known for their high tensile strength and excellent ductility, making them ideal for enhancing the toughness and durability of concrete. When added to concrete, these fibers can improve its resistance to cracking, shrinkage, and spalling during seismic events. The use of stainless steel fibers in earthquake-resistant concrete structures can help mitigate the detrimental effects of earthquakes. The fibers act as reinforcement, providing additional strength and preventing the propagation of cracks in the concrete. This reinforcement improves the overall structural integrity of the concrete, making it more resistant to the dynamic forces generated by earthquakes. Moreover, melt extract stainless steel fibers have a high melting point, corrosion resistance, and excellent thermal stability. These properties make them suitable for long-term applications in harsh environments, such as earthquake-prone areas. The fibers do not degrade over time, ensuring the long-term durability and effectiveness of the concrete structure. Additionally, melt extract stainless steel fibers have been extensively tested and proven to enhance the seismic performance of concrete structures. They comply with various international standards, such as ASTM and ACI, which ensure their quality and reliability. These fibers have been successfully used in a wide range of earthquake-resistant applications, including bridges, tunnels, high-rise buildings, and industrial structures. In conclusion, melt extract stainless steel fiber can indeed be used in earthquake-resistant concrete structures. Its high tensile strength, ductility, and resistance to cracking make it an excellent reinforcement material for enhancing the durability and seismic performance of concrete. By incorporating stainless steel fibers into concrete, engineers can effectively improve the resistance of structures to seismic forces, ensuring the safety and longevity of the infrastructure in earthquake-prone regions.

- Q: What is the recommended dosage of melt extract stainless steel fiber in concrete?

- The recommended dosage of melt extract stainless steel fiber in concrete can vary depending on the specific application and desired outcome. However, a general guideline is to add 1-2% by volume of stainless steel fiber to the concrete mix. This dosage range is commonly used to enhance the mechanical properties of the concrete, such as increasing its strength, toughness, and durability. It is important to note that the dosage of stainless steel fiber may need to be adjusted based on the specific requirements of the project, such as the desired level of reinforcement, exposure conditions, and the type of concrete being used. Consulting with a structural engineer or concrete specialist is recommended to determine the optimal dosage for a particular project. Additionally, it is important to ensure proper mixing and distribution of the stainless steel fibers within the concrete mix to achieve the desired benefits. This can be achieved through thorough mixing and/or the use of specialized equipment, such as fiber dosing machines or mixers with high shear capabilities. Ultimately, the recommended dosage of melt extract stainless steel fiber in concrete should be determined based on the specific project requirements and in consultation with experts in the field.

- Q: How does melt extract stainless steel fiber prevent cracking in concrete?

- Melt extract stainless steel fiber prevents cracking in concrete by improving its tensile strength and ductility. The fibers act as reinforcement, dispersing the stress throughout the concrete mixture and reducing the formation and propagation of cracks. This helps in enhancing the overall durability and structural integrity of the concrete.

- Q: How does melt extract stainless steel fiber improve the resistance to chemical attack in concrete?

- Melt extract stainless steel fiber is known for enhancing the resistance to chemical attack in concrete due to its unique properties and characteristics. When added to concrete mixtures, the stainless steel fibers act as a reinforcement that improves the durability and longevity of the concrete structure. One of the primary ways in which melt extract stainless steel fiber improves the resistance to chemical attack is by forming a physical barrier against corrosive substances. Concrete is generally susceptible to chemical attack from substances such as acids, alkalis, and chlorides, which can penetrate the concrete matrix and cause deterioration over time. However, the addition of stainless steel fibers creates a network of reinforcement within the concrete, which acts as a protective barrier against chemical intrusion. This, in turn, reduces the permeability of the concrete and prevents the corrosive substances from reaching and damaging the underlying steel reinforcement. Furthermore, melt extract stainless steel fiber also enhances the resistance to chemical attack by improving the mechanical properties of the concrete. The addition of stainless steel fibers increases the flexural strength, tensile strength, and impact resistance of the concrete, making it more resistant to cracking and spalling caused by chemical exposure. This improved mechanical performance helps to maintain the integrity of the concrete structure and prevents the ingress of corrosive substances through cracks and fissures. Moreover, stainless steel fibers also play a crucial role in minimizing the effects of chemical attack by reducing the formation of microcracks in the concrete. Chemical attack can lead to the formation of cracks and fractures in the concrete, which can further accelerate the deterioration process. However, the presence of stainless steel fibers helps to distribute the stress and load more evenly throughout the concrete, preventing the concentration of forces that can lead to crack formation. By minimizing the formation of microcracks, the stainless steel fibers effectively reduce the vulnerability of the concrete to chemical attack and enhance its overall durability. In conclusion, melt extract stainless steel fiber improves the resistance to chemical attack in concrete by forming a physical barrier against corrosive substances, enhancing the mechanical properties of the concrete, and minimizing the formation of microcracks. These combined effects result in a more durable and long-lasting concrete structure that is better able to withstand the detrimental effects of chemical exposure.

- Q: What is the typical aspect ratio of melt extract stainless steel fiber?

- The typical aspect ratio of melt extract stainless steel fiber is around 100:1 to 200:1.

Send your message to us

Melt Extract Stainless Steel Fiber - Straight Type Steel Fiber from CNBM International

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords