Melt Extract Stainless Steel Fiber - Straight Type Steel Fiber by CNBM International

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

1. Material: low carbon steel wire or stainless steel

2.Diameter: 0.4mm-1.0mm

3.Length: meet your requirements

4.tensile strength >1000Mpa

6.Feature: excellent tensile,high tenacity,against cracking,impact and fatigue

7.Uses: highway road surface,tunnel,building,airport road surface and so on .

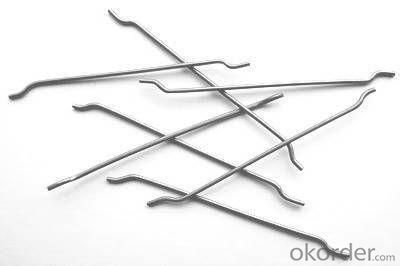

Straight Steel Fiber

1.ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

Picture

Steel fiber straight type

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: Can melt extract stainless steel fiber be used in thin concrete sections?

- Indeed, it is possible to employ melt extract stainless steel fiber in thin concrete sections. By incorporating stainless steel fibers into such sections, the mechanical properties and overall performance of the concrete can be significantly improved. These fibers effectively reinforce the concrete, bolstering its resistance to cracking and shrinkage. This becomes particularly crucial in thin sections, where the concrete is more susceptible to these concerns. Furthermore, the presence of stainless steel fibers enhances the durability and lifespan of the concrete, rendering it suitable for diverse applications, including thin sections.

- Q: How does melt extract stainless steel fiber affect the permeability of concrete to water?

- Melt extract stainless steel fiber improves the permeability of concrete to water. The fibers create a network within the concrete, reducing the size and number of capillary pores. This results in a denser and more impermeable structure, reducing water ingress and increasing the durability of the concrete.

- Q: Can melt extract stainless steel fiber be used in tunnel linings for underground mining?

- Yes, melt extract stainless steel fiber can be used in tunnel linings for underground mining. Stainless steel fibers are known for their high tensile strength, corrosion resistance, and durability, making them suitable for demanding applications such as mining tunnels. These fibers can enhance the structural integrity of the lining by providing reinforcement and preventing cracks or fractures. Additionally, the stainless steel material is resistant to chemical reactions, moisture, and temperature fluctuations commonly encountered in underground mining environments. This makes it a reliable choice for tunnel linings that need to withstand various challenges and ensure long-term stability.

- Q: Can melt extract stainless steel fiber be used in concrete overlays?

- Yes, melt extract stainless steel fiber can be used in concrete overlays.

- Q: Can melt extract stainless steel fiber be used in high-performance shotcrete mixtures?

- Yes, melt extract stainless steel fiber can be used in high-performance shotcrete mixtures. Stainless steel fibers are known for their high tensile strength, corrosion resistance, and durability, making them suitable for various applications including shotcrete. In high-performance shotcrete mixtures, the addition of stainless steel fibers can improve the overall performance of the material. The inclusion of stainless steel fibers in shotcrete can enhance its resistance to cracking, impact, and fatigue. These fibers act as reinforcement, providing additional strength and toughness to the shotcrete. They help to control shrinkage and reduce the formation of shrinkage cracks, which is crucial in high-performance applications where durability is a key requirement. Furthermore, stainless steel fibers can improve the ductility and flexural strength of shotcrete, allowing it to better withstand dynamic loads and harsh environments. This makes it particularly suitable for use in high-performance shotcrete applications such as tunnel linings, underground structures, bridge repairs, and other situations where high strength and durability are essential. It is important to note that the specific dosage and fiber length should be carefully determined based on the desired performance requirements and the characteristics of the shotcrete mixture. Consulting with a materials engineer or shotcrete specialist is recommended to ensure the proper selection and dosage of melt extract stainless steel fibers for high-performance shotcrete mixtures.

- Q: Can melt extract stainless steel fiber be used in parking garage construction?

- Yes, melt extract stainless steel fiber can be used in parking garage construction. Stainless steel fibers are commonly used in concrete to improve its structural performance and durability. They can help enhance the tensile and flexural strength of the concrete, reduce cracking and shrinkage, and increase resistance to corrosion and abrasion. In parking garages, where heavy loads, vehicle traffic, and exposure to moisture and chemicals are common, the use of stainless steel fibers can significantly improve the longevity and performance of the concrete. Additionally, stainless steel fibers can also enhance the fire resistance of concrete, making them suitable for parking garages where fire safety is crucial. Overall, melt extract stainless steel fiber is a suitable and effective reinforcement material for parking garage construction.

- Q: How does melt extract stainless steel fiber improve the ductility of shotcrete?

- The ductility of shotcrete is enhanced by melt extract stainless steel fiber, which improves its resistance to deformation and cracking. The inclusion of stainless steel fibers in the shotcrete mix forms a reinforced matrix that increases its tensile strength and flexural capacity. During the application of shotcrete, it undergoes a curing process that results in hardening and increased strength. However, shotcrete is susceptible to cracking when subjected to tensile stresses without any reinforcement. By integrating melt extract stainless steel fibers, the ductility of shotcrete is enhanced as the fibers distribute the tensile forces throughout the material, preventing the formation and spread of cracks. The exceptional properties of stainless steel, such as its high tensile strength and corrosion resistance, make it an ideal material for reinforcing shotcrete. The fibers are evenly dispersed within the shotcrete mix, creating a three-dimensional reinforcement system that improves its structural integrity. The addition of stainless steel fibers also enhances the overall durability of shotcrete. The fibers act as a barrier, preventing the entry of water and other harmful substances, thereby reducing the risk of corrosion and deterioration. This results in a longer service life and reduces the need for expensive maintenance and repairs. In conclusion, the presence of melt extract stainless steel fiber enhances the ductility of shotcrete by reinforcing its structure and improving its ability to withstand tensile stresses and deformation. Incorporating these fibers provides shotcrete with increased strength, durability, and resistance to cracking, ultimately enhancing its performance and extending its lifespan.

- Q: Can melt extract stainless steel fiber be used in seismic-resistant concrete applications?

- Yes, melt extract stainless steel fiber can be used in seismic-resistant concrete applications. Stainless steel fibers are commonly used as reinforcement in concrete to enhance its strength, durability, and ductility. In seismic-resistant concrete applications, stainless steel fibers help to improve the concrete's resistance to cracking and enhance its ability to withstand the dynamic forces generated during an earthquake. The melt extract stainless steel fibers are particularly suitable for such applications due to their high tensile strength, corrosion resistance, and ability to disperse uniformly within the concrete matrix. They effectively reinforce the concrete and provide enhanced crack control, reducing the risk of structural failure during seismic events. Therefore, using melt extract stainless steel fiber in seismic-resistant concrete can significantly improve the overall performance and safety of the structure.

- Q: What is the effect of melt extract stainless steel fiber on the curing time of concrete?

- Concrete's curing time can be significantly influenced by the addition of melt extract stainless steel fiber. Typically, stainless steel fibers are incorporated into concrete mixtures to enhance its mechanical properties, including strength, durability, and resistance to cracks. The presence of stainless steel fibers in concrete primarily impacts the curing time by improving the bond between the cement matrix and the aggregate. This improved bond leads to a faster rate of hydration, which is the chemical reaction between the cement and water that results in concrete hardening. As a result of this enhanced hydration process, concrete containing melt extract stainless steel fibers generally experiences quicker initial setting and strength development. Consequently, the concrete can achieve a sufficient level of hardness and strength more rapidly compared to plain concrete without fibers, ultimately reducing the overall curing time. Moreover, the use of stainless steel fibers also helps minimize plastic shrinkage cracking, which commonly occurs during the early stages of concrete curing when water content evaporates faster than the hydration reaction takes place. By reducing these cracks, the curing time can be further expedited as there is less need for repair or remediation. However, it is important to acknowledge that the specific impact of melt extract stainless steel fiber on curing time can vary based on factors such as fiber dosage, aggregate type, environmental conditions, and overall concrete mixture design. Therefore, it is crucial to conduct thorough testing and analysis to determine the precise influence of stainless steel fibers on the curing time of concrete in a specific application.

- Q: How does melt extract stainless steel fiber improve the resistance to cracking in concrete?

- Melt extract stainless steel fiber improves the resistance to cracking in concrete due to its unique properties and characteristics. When added to concrete, these fibers act as reinforcement by providing additional tensile strength and ductility to the material. The stainless steel fibers are uniformly dispersed throughout the concrete matrix, creating a three-dimensional network that enhances the overall structural integrity. This network effectively distributes and absorbs stresses, preventing the formation and propagation of cracks. Moreover, the high aspect ratio of these fibers, combined with their strong bond with the concrete matrix, enhances the load-bearing capacity of the material. This means that when subjected to external forces or thermal changes, the stainless steel fibers act as micro-reinforcements, effectively resisting crack formation and reducing their width and length. Additionally, the corrosion resistance of stainless steel fibers is a significant advantage. Unlike other types of fibers, stainless steel does not corrode, even in harsh environments or when exposed to chemicals. This corrosion resistance ensures the long-term durability of the concrete structure and prevents the deterioration of its mechanical properties. Furthermore, the melt extract stainless steel fibers improve the resistance to cracking by reducing shrinkage and creep in concrete. Shrinkage occurs as the concrete dries and cures, and it often leads to cracking. The addition of stainless steel fibers reduces the overall shrinkage of the concrete, minimizing the potential for cracks to form. In summary, the inclusion of melt extract stainless steel fibers in concrete significantly improves its resistance to cracking. These fibers enhance the tensile strength, ductility, load-bearing capacity, and corrosion resistance of the material, providing a more durable and long-lasting concrete structure.

Send your message to us

Melt Extract Stainless Steel Fiber - Straight Type Steel Fiber by CNBM International

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords