Melt Extract Stainless Steel Fiber - Steel Fiber Straight Type CNBM China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

1. Material: low carbon steel wire or stainless steel

2.Diameter: 0.4mm-1.0mm

3.Length: meet your requirements

4.tensile strength >1000Mpa

6.Feature: excellent tensile,high tenacity,against cracking,impact and fatigue

7.Uses: highway road surface,tunnel,building,airport road surface and so on .

Straight Steel Fiber

1.ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

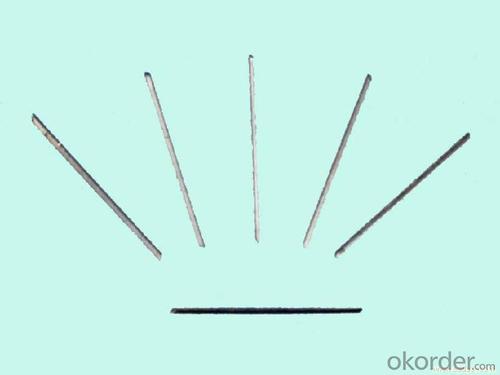

Picture

Steel fiber straight type

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: What are the advantages of using melt extract stainless steel fiber in concrete reinforcement?

- The utilization of melt extract stainless steel fiber in concrete reinforcement offers several benefits. To begin with, the inclusion of stainless steel fibers significantly enhances the overall durability and strength of concrete structures. These fibers serve as reinforcement, increasing the tensile and flexural strength of the concrete. Consequently, the concrete becomes more resistant to cracking and breaking, resulting in a longer lifespan and reduced maintenance and repair expenses. Moreover, stainless steel fibers play a crucial role in controlling the formation and propagation of cracks in concrete. By evenly distributing the load throughout the structure, the fibers prevent cracks from expanding and spreading. This ensures the integrity and stability of the concrete, which is especially advantageous in high-stress areas like bridges, highways, and industrial floors. Additionally, melt extract stainless steel fibers possess exceptional corrosion resistance. Unlike traditional steel reinforcement, these fibers do not rust or corrode when exposed to moisture or chemicals. This quality is of utmost importance in environments where corrosion is a concern, such as marine structures or areas with high chloride content. The corrosion resistance of stainless steel fibers guarantees the extended lifespan and optimal performance of the reinforced concrete. Furthermore, stainless steel fibers exhibit improved fire resistance properties. When subjected to high temperatures, the fibers function as a heat sink, absorbing and dissipating the heat energy. This effectively prevents the concrete from cracking or spalling, thus maintaining its structural integrity during fire incidents. This characteristic is particularly significant in buildings where fire safety is prioritized. Lastly, the utilization of melt extract stainless steel fibers in concrete reinforcement offers a more efficient and cost-effective solution in comparison to traditional reinforcement methods. The fibers can be easily incorporated into the concrete mix, eliminating the need for additional labor for reinforcement installation. This saves time and reduces construction costs. Moreover, the enhanced durability and reduced maintenance requirements of the reinforced concrete result in long-term cost savings. Overall, the utilization of melt extract stainless steel fiber in concrete reinforcement provides numerous advantages, including enhanced durability, crack control, corrosion resistance, fire resistance, and cost-effectiveness. These benefits make it an ideal choice for a wide range of concrete applications, ensuring the longevity, safety, and optimal performance of the structures.

- Q: Does melt extract stainless steel fiber improve the crack control of concrete elements?

- Yes, melt extract stainless steel fiber does improve the crack control of concrete elements.

- Q: What is the cost-effectiveness of using melt extract stainless steel fiber in concrete?

- The cost-effectiveness of using melt extract stainless steel fiber in concrete can vary depending on various factors. Firstly, the initial cost of incorporating stainless steel fibers into concrete can be higher compared to traditional reinforcement methods such as rebar or wire mesh. Stainless steel fibers are generally more expensive to produce and purchase, which can contribute to higher upfront costs. However, the cost-effectiveness of using stainless steel fiber in concrete lies in its long-term benefits and performance. Stainless steel fibers offer excellent durability and corrosion resistance, making them suitable for applications in harsh environments or where long-term structural integrity is required. By enhancing the tensile strength and crack resistance properties of concrete, stainless steel fibers can help increase the lifespan of the concrete structure. This, in turn, can lead to reduced maintenance and repair costs over the life cycle of the structure. Moreover, the use of stainless steel fibers can also provide cost savings by eliminating or reducing the need for additional reinforcement materials, such as rebar or mesh. The fibers can distribute the load more evenly throughout the concrete, reducing the potential for localized cracks or failures. Additionally, the labor and time required for installing stainless steel fibers is often less compared to traditional reinforcement methods. This can result in cost savings during the construction phase. It is important to consider the specific project requirements and the expected lifespan of the concrete structure when evaluating the cost-effectiveness of using stainless steel fibers. While the initial costs may be higher, the long-term benefits and reduced maintenance expenses can make it a cost-effective choice in certain applications.

- Q: How does melt extract stainless steel fiber improve the toughness of concrete?

- Melt extract stainless steel fiber improves the toughness of concrete by enhancing its crack resistance and durability. The steel fibers act as reinforcement within the concrete matrix, distributing and absorbing stress and preventing the propagation of cracks. This improves the overall strength and longevity of the concrete, making it more resistant to impact, flexural, and fatigue loads.

- Q: How does the aspect ratio of melt extract stainless steel fiber affect its performance?

- The aspect ratio of melt extract stainless steel fiber refers to the ratio of its length to diameter. A higher aspect ratio generally leads to improved performance of the fiber. This is because a higher aspect ratio allows for a greater surface area and better interlocking within the matrix material, resulting in enhanced mechanical properties such as increased tensile strength, improved crack resistance, and better overall reinforcement. Additionally, a higher aspect ratio can enhance the fiber's ability to distribute stress evenly, leading to improved durability and longevity.

- Q: What is the effect of melt extract stainless steel fiber on the fatigue resistance of concrete?

- Concrete's fatigue resistance can be greatly improved by adding melt extract stainless steel fiber. These fibers, which are known for their strength and durability, are well-suited for enhancing the performance of concrete in applications where fatigue is a concern. The main benefit of melt extract stainless steel fiber in terms of concrete's fatigue resistance is its ability to reinforce the material. These fibers form a distributed network within the concrete, effectively connecting any cracks that may occur during repeated loading. By preventing crack propagation and reducing their width, the presence of stainless steel fibers enhances the overall fatigue strength of the concrete. Moreover, the high ductility and corrosion resistance of stainless steel fibers also contribute to the improved fatigue resistance of concrete. These fibers have the capability to absorb and distribute stress energy, thereby reducing stress concentration in specific areas. This energy dissipation ability helps to prevent the formation and growth of cracks, ultimately enhancing the fatigue performance of the concrete. Furthermore, the addition of melt extract stainless steel fiber can enhance the toughness and durability of concrete as a whole. These fibers increase the resistance of the material to impact and dynamic loading, making it more resistant to fatigue failure. This is particularly advantageous in structures that experience repetitive loading, such as bridges, pavements, and industrial floors. In conclusion, the incorporation of melt extract stainless steel fiber significantly enhances the fatigue resistance of concrete. The reinforcement provided by these fibers, along with their high ductility and corrosion resistance, improves crack bridging, reduces crack width, and enhances the overall toughness of the material. As a result, structures reinforced with stainless steel fibers exhibit improved durability and longer service life, making them well-suited for applications where fatigue is a concern.

- Q: How does melt extract stainless steel fiber improve the impact resistance of shotcrete?

- Melt extract stainless steel fiber serves as a reinforcement material that is incorporated into shotcrete, a versatile construction material with various uses. The inclusion of this stainless steel fiber in shotcrete greatly enhances its ability to withstand impact. The primary reason for this enhancement stems from the unique properties of stainless steel fiber. Firstly, stainless steel possesses a high tensile strength, allowing it to endure significant force without breaking or distorting. This characteristic enables the stainless steel fiber to effectively distribute and absorb the energy from impacts, minimizing the occurrence of cracks or fractures in the shotcrete. Moreover, the melt extract process employed to manufacture these fibers ensures a consistent and uniform shape, size, and distribution. This uniformity contributes to the overall stability and durability of the shotcrete, rendering it more resistant to impact loads. Additionally, the addition of stainless steel fibers to shotcrete enhances its ductility, which refers to its ability to deform without fracturing. By increasing the ductility of shotcrete, the stainless steel fibers enable it to absorb energy more effectively during impact events, preventing sudden failures or catastrophic damage. In summary, the utilization of melt extract stainless steel fibers in shotcrete significantly bolsters its impact resistance by augmenting its tensile strength, stability, durability, and ductility. Consequently, shotcrete reinforced with stainless steel fibers becomes an optimal choice for applications where impact loads are anticipated, such as in tunnel linings, bridge abutments, or protective barriers.

- Q: What is the effect of melt extract stainless steel fiber on the crack width in shotcrete?

- The crack width in shotcrete is significantly affected by the use of melt extract stainless steel fiber. Stainless steel fibers are renowned for their exceptional tensile strength and durability, making them the ideal reinforcement material for shotcrete applications. Upon addition to the shotcrete mix, the stainless steel fibers are uniformly dispersed throughout the material, forming a reinforcement network that enhances its structural integrity. This reinforcement effectively reduces crack width in the shotcrete by bridging the cracks and preventing their propagation. The melt extract stainless steel fibers serve as micro-reinforcement within the shotcrete, amplifying its ductility and resistance to cracking. This is especially advantageous in areas with high stress concentrations or where cracking is prevalent, such as tunnels, underground structures, or retaining walls. By diminishing crack width in shotcrete, the utilization of melt extract stainless steel fibers enhances the material's overall durability and longevity. It elevates its ability to withstand environmental factors, including freeze-thaw cycles, chemical exposure, or mechanical loading, all of which can trigger crack propagation and subsequent deterioration. Moreover, the reduced crack width in shotcrete also enhances its aesthetic appearance by minimizing visible indications of cracking on the surface. This is particularly crucial in architectural applications where the shotcrete is exposed and serves as a decorative element. To summarize, the incorporation of melt extract stainless steel fibers into shotcrete yields positive effects on crack width in the material. It enhances structural integrity, durability, crack resistance, and overall aesthetic appearance, rendering it a valuable reinforcement option for shotcrete applications.

- Q: What is the effect of melt extract stainless steel fiber on the workability of concrete?

- The addition of melt extract stainless steel fiber to concrete can have a significant effect on its workability. Stainless steel fibers are typically added to concrete to enhance its mechanical properties and improve its resistance to cracking, impact, and abrasion. One of the main benefits of using stainless steel fiber in concrete is that it increases its tensile strength and flexural strength. This means that the concrete becomes more resistant to bending or cracking under pressure, which is particularly important in structural applications. The incorporation of stainless steel fibers also enhances the overall durability and long-term performance of the concrete. However, the addition of stainless steel fibers can also have some drawbacks in terms of workability. The fibers can cause an increase in the viscosity of the concrete mix, making it more difficult to handle and place. This can result in a decrease in the fluidity and cohesiveness of the mix, making it harder to achieve the desired finish and surface texture. To overcome these challenges, it is important to carefully control the dosage and length of the stainless steel fibers used in the concrete mix. By optimizing the fiber content and distribution, it is possible to maintain a good balance between workability and the desired mechanical properties. In summary, the effect of melt extract stainless steel fiber on the workability of concrete is a trade-off between improved mechanical properties and potential challenges in handling and placing the mix. With careful consideration of the fiber dosage and mix design, it is possible to achieve a concrete mix that provides both enhanced performance and satisfactory workability.

- Q: How does melt extract stainless steel fiber affect the curing process of concrete?

- Melt extract stainless steel fiber plays a crucial role in the curing process of concrete, impacting it significantly. When integrated into the concrete mixture, these fibers disperse evenly throughout, offering reinforcement and enhancing the overall strength and durability of the cured concrete. As a reinforcement material, the stainless steel fibers strengthen the concrete's flexural strength, toughness, and resistance to cracking. This reinforcement effect is particularly advantageous in minimizing early-age cracking, plastic shrinkage cracking, and drying shrinkage cracking, which are common during the curing process. Furthermore, the stainless steel fibers improve the bond between the cement paste and aggregates, preventing internal micro-cracking and enhancing the concrete's ability to withstand stresses and loads. This improved bond also lowers the risk of delamination and spalling, thereby increasing the cured concrete's longevity and durability. Additionally, melt extract stainless steel fibers assist in controlling crack formation and propagation in the concrete. By bridging the cracks, these fibers limit their width and restrict their growth, effectively minimizing the potential for structural failure and enhancing the concrete's resistance to external forces. Moreover, the stainless steel fibers aid in managing plastic shrinkage and settlement cracking by reducing the evaporation rate of water from the concrete surface. This slower drying process enables a more controlled and uniform curing, resulting in improved overall strength and reduced permeability of the concrete. In conclusion, incorporating melt extract stainless steel fibers into concrete has a significant impact on the curing process, enhancing the concrete's strength, durability, resistance to cracking, and overall performance. These fibers provide reinforcement, improve bond strength, control crack formation, and reduce shrinkage, ultimately resulting in higher quality and longer-lasting cured concrete.

Send your message to us

Melt Extract Stainless Steel Fiber - Steel Fiber Straight Type CNBM China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords