Melt Extract Stainless Steel Fiber Straight Type China Company CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

Specifications

Produces shear type, steel wire type, cut type, stainless type, and micro wire type steel fiber. It is used for concret.

SPECIFICATION

TYPE | SIZE | tensile strength |

ENDHOOKED STEEL FIBER | 0.5×0.5×30 mm | 850Mpa min |

0.6×0.7×35 mm | 850Mpa min | |

0.5×0.5×30 mm | 1000MPA min | |

0.6×35 mm | 1000MPA min | |

0.9×60 mm | 1000MPA min | |

CORRUGATED STEEL FIBER | 0.25×0.25×10 mm | 380Mpa min |

0.25×0.25×14 mm | 380Mpa min | |

0.5×0.7×32 mm | 380MPA min |

OTHER SPECIFICATIONS CAN BE DISCUSSED AS PER BUYER’S OPTION

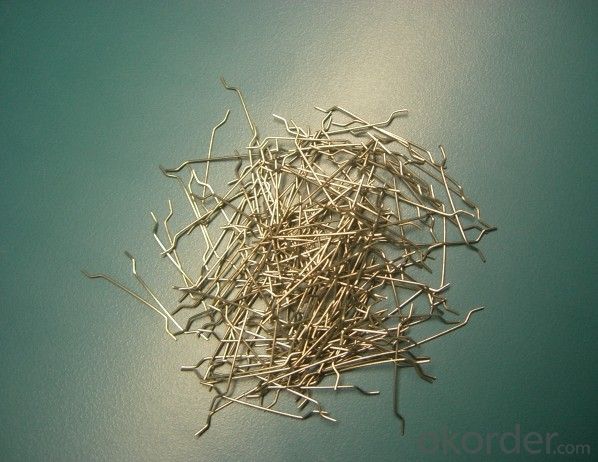

Picture

Steel fiber straight type

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: Can melt extract stainless steel fiber be used in sports field pavements?

- Yes, melt extract stainless steel fiber can be used in sports field pavements. Its high tensile strength and corrosion resistance make it suitable for withstanding the heavy foot traffic and weather conditions typically found in sports fields. Additionally, its durability helps enhance the longevity and performance of the pavement, making it a viable option for such applications.

- Q: What is the effect of melt extract stainless steel fiber on the compressive strength of concrete?

- Concrete can significantly benefit from the use of melt extract stainless steel fiber, as it enhances its compressive strength. By adding stainless steel fibers to the concrete mixture, the mechanical properties of the concrete are improved and its performance under compressive loading is enhanced. The incorporation of stainless steel fibers in concrete serves to increase its tensile strength, ductility, and toughness. These fibers act as reinforcement within the concrete matrix, providing additional strength and preventing crack propagation. When subjected to compressive forces, the fibers distribute stress more evenly throughout the concrete, resulting in a reduction in stress concentration points and an overall improvement in strength. Moreover, the presence of melt extract stainless steel fibers in concrete can enhance its resistance to temperature variations, shrinkage, and cracking. This is especially advantageous in areas where the concrete is exposed to extreme weather conditions or undergoes thermal cycling. Furthermore, the use of stainless steel fibers improves the durability and longevity of concrete structures. By inhibiting crack growth and propagation, the fibers contribute to a more durable and long-lasting concrete. Nevertheless, it is important to consider that the effect of melt extract stainless steel fibers on the compressive strength of concrete may vary depending on factors such as fiber content, aspect ratio, and distribution within the concrete matrix. Therefore, it is crucial to carefully assess these factors and conduct proper testing to determine the optimal fiber dosage and distribution for achieving the desired enhancement in compressive strength. In conclusion, melt extract stainless steel fibers positively impact the compressive strength of concrete by improving its mechanical properties, enhancing its resistance to cracking, and increasing its durability.

- Q: Can melt extract stainless steel fiber improve the resistance of concrete to chemical attack?

- Indeed, the incorporation of melt extract stainless steel fibers has the ability to enhance the resistance of concrete against chemical attack. Renowned for their exceptional resistance to corrosion and chemical reactions, stainless steel fibers possess unique properties that make them an ideal choice for improving the durability of concrete. When introduced into the concrete mixture, they form a lattice-like structure, thereby augmenting the overall strength and endurance of the material. This intricate network of stainless steel fibers acts as a formidable barrier against chemical agents, effectively thwarting their infiltration into the concrete matrix and averting any potential harm. Concrete is susceptible to chemical attacks triggered by a variety of factors, including the exposure to aggressive chemicals, acidic solutions, chlorides, sulfates, and more. Such attacks can cause deterioration of the concrete structure, leading to a reduced lifespan. However, by integrating melt extract stainless steel fibers into the concrete blend, the concrete's resistance to chemical attack is significantly enhanced. The stainless steel fibers serve as a reinforcement within the concrete, bestowing upon it additional robustness and stability. They work to decrease the permeability of the concrete, rendering it less susceptible to chemical penetration. Moreover, these stainless steel fibers elevate the overall durability and toughness of the concrete, thereby rendering it more impervious to cracking and spalling induced by chemical reactions. Moreover, melt extract stainless steel fibers also contribute to the concrete's ability to withstand temperature fluctuations. Possessing a remarkably high melting point, they are capable of withstanding extreme heat. This attribute proves exceedingly advantageous in environments where chemical reactions may occur due to elevated temperatures. To conclude, the integration of melt extract stainless steel fibers into concrete holds immense potential in bolstering its resistance against chemical attack. These fibers function as a protective barrier, decrease permeability, and enhance the overall durability and strength of the concrete. Consequently, they represent an effective solution for structures that are exposed to harsh chemical environments, ultimately prolonging the lifespan of the concrete and ensuring its longevity.

- Q: How does melt extract stainless steel fiber enhance the resistance to impact loads in concrete?

- Melt extract stainless steel fiber enhances the resistance to impact loads in concrete through its unique properties and behavior. When added to concrete, stainless steel fibers disperse uniformly throughout the mixture, creating a three-dimensional reinforcement network. This network acts as a secondary reinforcement system, increasing the concrete's ability to resist impact loads. The high tensile strength and ductility of stainless steel fibers play a crucial role in enhancing impact resistance. Unlike traditional reinforcement materials like steel bars or mesh, stainless steel fibers have a much higher tensile strength, enabling them to distribute the impact energy more effectively. This prevents the formation of cracks and improves the overall durability of the concrete. Additionally, stainless steel fibers have excellent bonding characteristics with the concrete matrix. This strong bond ensures that the fibers remain in place even under heavy impact loads, effectively transferring the load from the surface of the concrete to the fiber reinforcement system. This mechanism helps to dissipate the impact energy and reduce the risk of surface spalling or cracking. Furthermore, the unique aspect of melt extract stainless steel fibers lies in their ability to withstand elevated temperatures. This is particularly important in situations where impact loads may be accompanied by high temperatures, such as fire incidents or explosions. The stainless steel fibers can maintain their structural integrity even at high temperatures, providing continuous reinforcement to the concrete and enhancing its resistance to impact under extreme conditions. In summary, melt extract stainless steel fiber enhances the resistance to impact loads in concrete by creating a strong and uniform reinforcement network. Its high tensile strength, excellent bonding characteristics, and ability to withstand elevated temperatures contribute to the overall durability and impact resistance of the concrete.

- Q: What is the effect of melt extract stainless steel fiber on the modulus of elasticity of concrete?

- By incorporating melt extract stainless steel fibers into concrete, the modulus of elasticity can be positively influenced. The modulus of elasticity refers to the capacity of a material to deform elastically under stress and subsequently return to its original shape upon stress removal. The stainless steel fibers serve as reinforcement within the concrete matrix, thereby enhancing its mechanical properties. These fibers augment the tensile strength of the concrete, impeding the propagation of cracks and increasing its ability to withstand bending or flexural stresses. Consequently, the modulus of elasticity of the concrete is enhanced. The inclusion of melt extract stainless steel fibers aids in the uniform distribution of stress throughout the concrete, diminishing stress concentration at specific points and improving the overall structural integrity. This enables the concrete to bear heavier loads and enhances its durability. Moreover, the presence of stainless steel fibers further strengthens the bond between the concrete matrix and the fibers themselves. This fortified bond facilitates the transmission of stress from the matrix to the fibers, thereby amplifying the overall strength and rigidity of the concrete. In summary, the incorporation of melt extract stainless steel fibers into concrete has a positive influence on the modulus of elasticity by enhancing the material's tensile strength, crack resistance, and overall durability.

- Q: Does melt extract stainless steel fiber improve the resistance to chloride ingress in shotcrete?

- The utilization of melt extract stainless steel fibers indeed enhances the capability of shotcrete to withstand chloride ingress. Concrete structures are susceptible to corrosion caused by chloride ions, particularly in marine environments or areas with high chloride salt exposure. By incorporating melt extract stainless steel fibers into the shotcrete mix, the durability and resistance of the concrete against chloride penetration are significantly improved. Melt extract stainless steel fibers are specially designed for reinforcing concrete and shotcrete applications. These fibers are manufactured using top-notch stainless steel material, which possesses exceptional corrosion resistance properties. When introduced into the shotcrete mix, the stainless steel fibers establish a three-dimensional network within the concrete matrix, effectively distributing stress and preventing crack formation. Regarding resistance against chloride ingress, the presence of melt extract stainless steel fibers acts as a physical barrier that hinders the movement of chloride ions into the concrete. The fibers create a complex pathway for the chloride ions to traverse, consequently decelerating their penetration rate. This, in turn, greatly diminishes the likelihood of corrosion initiation and propagation within the concrete. Moreover, melt extract stainless steel fibers enhance the overall durability of shotcrete by increasing its resistance to freeze-thaw cycles, abrasion, impact, and other forms of deterioration. This extended lifespan further contributes to the augmented resistance against chloride ingress, as the concrete remains structurally intact and less susceptible to corrosion induced by chloride. It is crucial to acknowledge that although melt extract stainless steel fibers offer significant advantages in terms of chloride ingress resistance, they should be used in combination with other corrosion prevention measures, such as appropriate concrete cover, waterproofing systems, and suitable concrete mix design. Additionally, the dosage and distribution of stainless steel fibers within the shotcrete mixture should be meticulously determined based on the specific demands and exposure conditions of the project.

- Q: Does melt extract stainless steel fiber enhance the bond strength between concrete layers?

- The inclusion of melt extract stainless steel fiber indeed heightens the bond strength between layers of concrete. By incorporating stainless steel fibers into concrete mixtures, the mechanical properties, specifically the bond strength between layers, are enhanced. As the concrete solidifies, the stainless steel fibers disperse evenly throughout the mixture, reinforcing it and augmenting the overall strength. This reinforcement fortifies the bond between layers, rendering it more resilient against cracking, delamination, and other forms of failure. Additionally, the integration of melt extract stainless steel fibers can enhance the durability and longevity of the concrete structure by diminishing the risk of spalling and increasing its resistance to impacts and vibrations. Ultimately, the utilization of melt extract stainless steel fiber in concrete significantly improves the bond strength between layers, elevating the performance and lifespan of the concrete structure.

- Q: Can melt extract stainless steel fiber be used in architectural facades or cladding systems?

- Yes, melt extract stainless steel fiber can be used in architectural facades or cladding systems. It offers excellent strength and durability, making it suitable for enhancing the structural integrity and aesthetics of buildings. Additionally, its resistance to corrosion and weathering makes it an ideal choice for long-lasting architectural applications.

- Q: How does melt extract stainless steel fiber impact the shrinkage cracking of concrete pavements?

- Melt extract stainless steel fiber helps reduce shrinkage cracking in concrete pavements by improving the overall tensile strength and ductility of the concrete. The fibers act as reinforcement, dispersing stress and controlling crack propagation, resulting in a more durable and crack-resistant pavement.

- Q: What is the impact of melt extract stainless steel fiber on the shrinkage of concrete?

- The impact of melt extract stainless steel fiber on the shrinkage of concrete is that it helps to reduce or mitigate the shrinkage cracks that can occur during the curing and drying process of concrete. The steel fibers provide reinforcement and improve the overall strength and durability of the concrete, thereby reducing the potential for shrinkage and cracking.

Send your message to us

Melt Extract Stainless Steel Fiber Straight Type China Company CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords