Melt Extract Stainless Steel Fiber Straight Type China from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

steel fiber reinforced refractory : Easy to stirb. Evenly dispersedc. Decentralized energy and reduce stress concentration

Such steel fiber using the technology into a row of single steel fiber bonding with water-soluble glue, to ensure that the steel fiber uniformly dispersed in concret, easily stirred, eliminate agglomerate phenomena such as, due to the bonding of steel fiberrows technology, steel fibers in concrete can be evenly distributed, so that the concrete structure by the impact of steel fibers can absorb impact energy, reduce stress concentration, effectively control the emergence and development of cracks in the concrete, to extend the structural life.

As reliable and efficient concrete reinforcement material, it is widely uesd in buildings, bridges, thin roof engineering, highway etc.

In bonding steel fiber concrete internal steel fiber, as long as ramming close-grained, and air separation, steel fiber generally don't happen corrosion phenomena. Dew in the concrete surface or in the crack width more than 0.25 mm, jumper cracks in the steel fiber, vulnerable to corrosion phenomena.

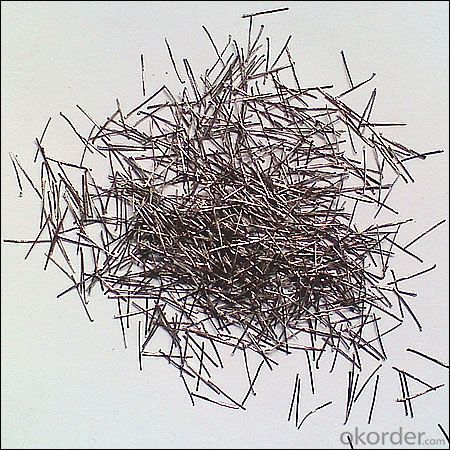

Picture

Steel fiber straight type

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: What is the effect of melt extract stainless steel fiber on the thermal expansion of concrete?

- The thermal expansion of concrete is significantly affected by melt extract stainless steel fibers. When incorporated into the concrete mixture, these fibers provide reinforcement and contribute to the enhancement of the concrete's overall strength and durability. In terms of thermal expansion, stainless steel fibers exhibit a low coefficient of thermal expansion, indicating minimal expansion or contraction in response to temperature changes. This characteristic serves to mitigate the adverse effects of thermal expansion on concrete. Concrete, on the other hand, demonstrates a relatively high coefficient of thermal expansion, resulting in substantial expansion and contraction with fluctuations in temperature. Consequently, this may lead to cracking, deformation, and other types of damage. Nevertheless, the addition of melt extract stainless steel fibers to the concrete aids in the uniform distribution of stress caused by thermal expansion throughout the material. As a result, the likelihood of cracking and damage is reduced. Moreover, the stainless steel fibers also enhance the mechanical properties of the concrete as a whole, rendering it more resistant to various forces, including thermal expansion. These fibers function as reinforcement, elevating the tensile strength and ductility of the concrete, thereby enabling it to withstand the stresses and strains arising from thermal expansion. In summary, the inclusion of melt extract stainless steel fibers in concrete has a positive impact on the material's thermal expansion properties. It serves to mitigate the negative consequences of thermal expansion, minimize cracking and damage, and enhance the overall durability and strength of the concrete.

- Q: Does melt extract stainless steel fiber improve the resistance to carbonation in concrete?

- Yes, melt extract stainless steel fiber can improve the resistance to carbonation in concrete.

- Q: Can melt extract stainless steel fiber be used in fiber-reinforced cementitious composites (FRCCs)?

- Yes, melt extract stainless steel fiber can be used in fiber-reinforced cementitious composites (FRCCs). Melt extract stainless steel fibers are often chosen for their high tensile strength, corrosion resistance, and durability. When added to cementitious materials, these fibers can enhance the flexural strength, toughness, and crack resistance of the composite. They can also improve the overall performance and longevity of FRCCs in various applications such as structural elements, pavements, and precast products. The use of melt extract stainless steel fiber in FRCCs offers increased structural integrity, reduced maintenance requirements, and improved resistance to environmental factors, making it a suitable choice for reinforcing cementitious composites.

- Q: Can melt extract stainless steel fiber be used in marine structures?

- Certainly, melt extract stainless steel fiber is applicable for utilization in marine structures. Stainless steel possesses exceptional resistance to corrosion, rendering it a suitable material for deployment in marine settings where exposure to saltwater and high humidity is prevalent. The incorporation of melt extract stainless steel fibers can enhance the reinforcement of concrete or other construction materials employed in marine structures, thereby delivering augmented strength and durability. These fibers exhibit resistance to rust and possess the capability to withstand the harsh conditions commonly encountered in marine environments, thus making them an exceptional selection for marine structures such as piers, docks, and offshore platforms. Moreover, the utilization of stainless steel fibers can contribute to the overall performance and lifespan enhancement of these structures, thereby diminishing long-term maintenance and repair expenses.

- Q: What is the effect of melt extract stainless steel fiber on the deflection of concrete beams?

- The effect of melt extract stainless steel fiber on the deflection of concrete beams is that it improves the flexural strength and reduces the cracking and deflection of the beams. The presence of stainless steel fibers in the concrete mixture enhances the overall performance of the beams by increasing their load-bearing capacity and resistance to bending. This results in a more durable and structurally sound concrete beam with reduced deflection under heavy loads.

- Q: Can melt extract stainless steel fiber enhance the resistance of concrete to chemical attack?

- Concrete's resistance to chemical attack can be enhanced by melt extract stainless steel fiber. Stainless steel fibers are well-known for their excellent corrosion resistance, durability, and high melting point. By adding these fibers to concrete, they function as reinforcement, increasing its overall strength and resistance to various forms of degradation, including chemical attack. Chemical attack on concrete occurs when aggressive substances, such as acids, alkalis, or salts, come into contact with the concrete surface. This can result in the deterioration of the concrete, including loss of strength, cracking, and eventual failure. However, by incorporating melt extract stainless steel fibers into the concrete mix, the concrete's resistance to chemical attack is significantly improved. The stainless steel fibers create a network within the concrete, which serves as an additional barrier against the penetration of aggressive chemicals. This network helps prevent the diffusion of ions and the entry of moisture, both of which are crucial factors in chemical attack. Additionally, the stainless steel fibers function as reinforcement, enhancing the overall durability and strength of the concrete. Moreover, melt extract stainless steel fibers possess a high melting point, enabling them to withstand the elevated temperatures that can arise during chemical reactions. This ensures that the fibers do not melt or deteriorate when exposed to aggressive chemicals, guaranteeing their effectiveness in enhancing the concrete's resistance. In conclusion, the addition of melt extract stainless steel fiber to concrete significantly improves its resistance to chemical attack. These fibers' corrosion resistance, durability, and high melting point make them an effective reinforcement against aggressive substances, enhancing the concrete's overall durability and lifespan.

- Q: Can melt extract stainless steel fiber be used in parking lot pavements?

- Yes, melt extract stainless steel fiber can be used in parking lot pavements. It is often added to concrete mixtures to enhance the strength and durability of the pavement, making it more resistant to cracking and wear. The stainless steel fiber reinforcement helps to increase the lifespan of the parking lot and reduce maintenance requirements.

- Q: Can melt extract stainless steel fiber improve the impact resistance of concrete?

- Yes, melt extract stainless steel fiber can improve the impact resistance of concrete. Stainless steel fibers are known for their high tensile strength, which helps to enhance the overall durability and toughness of the concrete. When added to the concrete mix, these fibers act as reinforcement and prevent the propagation of cracks under impact or dynamic loading conditions. The steel fibers distribute the stress more evenly throughout the concrete matrix, reducing the likelihood of brittle failure and increasing the impact resistance. Additionally, the melt extract stainless steel fibers have a high aspect ratio, meaning they are long and thin, which further enhances their ability to improve the impact resistance of concrete. Overall, incorporating melt extract stainless steel fiber in concrete can significantly enhance its ability to withstand impact and dynamic loads, making it a preferred choice for applications where impact resistance is critical, such as in industrial flooring, pavements, and structural elements subjected to high loads.

- Q: What is the recommended testing procedure for melt extract stainless steel fiber in concrete?

- The recommended testing procedure for melt extract stainless steel fiber in concrete typically involves conducting a series of tests to evaluate its performance and compatibility. This may include evaluating the fiber's physical properties, such as diameter, length, and aspect ratio, through microscopic analysis. Additionally, assessing the fiber's tensile strength, corrosion resistance, and bond strength with concrete is crucial. Various standardized tests, such as ASTM C1550 and ASTM C1609, can be employed to determine these characteristics. Lastly, it is important to conduct field trials to observe the fiber's performance in real-world conditions and ensure its suitability for the intended application.

- Q: Can melt extract stainless steel fiber be used in fiber-reinforced shotcrete?

- Yes, melt extract stainless steel fiber can be used in fiber-reinforced shotcrete. Stainless steel fibers are commonly used in shotcrete applications due to their high tensile strength, corrosion resistance, and durability. The melt extract process ensures uniform and consistent fiber properties, making it suitable for reinforcing shotcrete. The addition of stainless steel fibers to shotcrete enhances its mechanical properties, such as flexural and impact strength, crack resistance, and ductility. This improves the overall performance and longevity of the shotcrete structure. However, the specific application requirements, fiber dosage, and mix design should be considered to ensure proper and effective utilization of the stainless steel fibers in the fiber-reinforced shotcrete.

Send your message to us

Melt Extract Stainless Steel Fiber Straight Type China from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords