Melt Extract Stainless Steel Fiber End Hook Glued Steel Fiber from CNBM China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

Place of Origin: Tianjin, China (Mainland)

Model Number: 0.50 mm

Material: Steel

Production Process: Cold drawn

Lengh: 35

Type: 1

Compressive Strength: >1200MPa

Aspect ratio: 70

Standard: ASTM A820M-11

Section Shape: Circular

Application: Concrete Reinforcement

Packaging & Delivery

| Packaging Details: | 20 kg/Bag,50 bags/Pallet or 1,000kg/ Bulk Bag |

|---|---|

| Delivery Detail: | 1 Month |

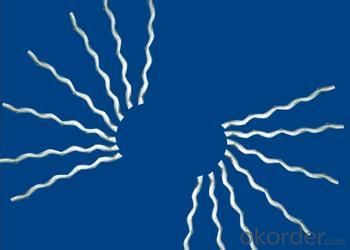

Product Description

| Diameter | 0.50 mm | ||

| Length | 35 mm | ||

| Aspect Ratio | 70 | ||

| Tensile strength | 1200 MPa | ||

| Type | Cold drawn Steel Fiber | ||

| End | Hooked-end Steel Fiber | ||

| Glued/Loose | Glued Steel Fiber | ||

| Bending Angle | 45°(min.30°) | ||

| Usage & Performance | Floor:Trafficked areas and Industrial floors | ||

| Shotcrete :Slope stabilization and Final lining | |||

| Precast concrete:Pipe and Railway sleepers | |||

| Packing | Standard Export Pallet Packing | Bag Packing | 20 kg/Bag,50 bags/Pallet |

| Bulk Packing | 1,000kg/ Bulk Bag | ||

| Loading Quantity | 20’GP | 20-25 Tonne/Tonnes | |

| 40’GP | 25-27 Tonne/Tonnes | ||

| 40’HQ | 25-27 Tonne/Tonnes | ||

| MOQ | 1 kg for trial order | ||

| Supply Ability | 10,000 Tonne/Tonnes per Year | ||

| Payment Terms | T/T or L/C at sight | ||

| Delivery Time | Within 15 days after receiving deposit or original L/C at sight | ||

| Certification | ISO9001:2000, CE, | ||

| Product | Diameter (mm) | Length (mm) | Aspect Ratio | Type | Packing |

| G-6030 | 0.5 | 30 | 60 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6535 | 0.55 | 35 | 65 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6035 | 0.6 | 35 | 60 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-8060 | 0.75 | 60 | 80 | Glued | 20 kg/Bag, 50 bags/Pallet |

| G-6060 | 0.9 | 60 | 60 | Glued | 20 kg/Bag, 50 bags/Pallet |

| G-6030 | 0.5 | 30 | 60 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6535 | 0.55 | 35 | 65 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6035 | 0.6 | 35 | 60 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-8060 | 0.75 | 60 | 80 | Loose | 20 kg/Bag, 50 bags/Pallet |

| G-6060 | 0.9 | 60 | 60 | Loose | 20 kg/Bag, 50 bags/Pallet |

- Q: Can melt extract stainless steel fiber be used in precast concrete products?

- Precast concrete products can indeed benefit from the utilization of melt extract stainless steel fiber. Such fibers are a reinforcement material that can be incorporated into concrete mixes for the purpose of enhancing their strength and durability. By improving the concrete's tensile strength and resistance to cracking, melt extract stainless steel fiber enables its suitability for various applications, including precast concrete products. During the batching process, the stainless steel fibers are typically blended into the concrete mixture and evenly dispersed throughout. This reinforcement proves especially advantageous for precast concrete products subjected to substantial loads or harsh environmental conditions. The inclusion of melt extract stainless steel fiber effectively prevents cracking and extends the overall lifespan of the precast concrete product.

- Q: What is the effect of melt extract stainless steel fiber on the deflection of concrete beams?

- The effect of melt extract stainless steel fiber on the deflection of concrete beams can be significant. When stainless steel fibers are added to concrete, they improve the overall toughness and ductility of the material. This results in increased resistance to cracking and improved structural performance. The addition of melt extract stainless steel fibers helps to distribute the load more evenly throughout the concrete matrix, reducing the concentration of stress at specific points. This leads to a decrease in deflection, as the fibers reinforce the concrete and prevent excessive bending under load. Stainless steel fibers also enhance the bond between the concrete matrix and the reinforcing steel bars, resulting in improved composite action. This further contributes to reducing deflection in concrete beams. Moreover, the thermal stability of stainless steel fibers allows them to maintain their integrity even at high temperatures. This makes them particularly effective in reinforcing concrete beams subjected to fire or elevated temperatures, as they help to minimize the effects of thermal expansion and contraction. In summary, the addition of melt extract stainless steel fibers to concrete beams has a positive effect on their deflection. The fibers improve the overall toughness, distribute the load more evenly, enhance the bond with reinforcing steel bars, and provide thermal stability. These combined effects result in reduced deflection and improved structural performance of concrete beams.

- Q: Can melt extract stainless steel fiber enhance the resistance of concrete to chemical attack?

- Concrete's resistance to chemical attack can be enhanced by melt extract stainless steel fiber. Stainless steel fibers are well-known for their excellent corrosion resistance, durability, and high melting point. By adding these fibers to concrete, they function as reinforcement, increasing its overall strength and resistance to various forms of degradation, including chemical attack. Chemical attack on concrete occurs when aggressive substances, such as acids, alkalis, or salts, come into contact with the concrete surface. This can result in the deterioration of the concrete, including loss of strength, cracking, and eventual failure. However, by incorporating melt extract stainless steel fibers into the concrete mix, the concrete's resistance to chemical attack is significantly improved. The stainless steel fibers create a network within the concrete, which serves as an additional barrier against the penetration of aggressive chemicals. This network helps prevent the diffusion of ions and the entry of moisture, both of which are crucial factors in chemical attack. Additionally, the stainless steel fibers function as reinforcement, enhancing the overall durability and strength of the concrete. Moreover, melt extract stainless steel fibers possess a high melting point, enabling them to withstand the elevated temperatures that can arise during chemical reactions. This ensures that the fibers do not melt or deteriorate when exposed to aggressive chemicals, guaranteeing their effectiveness in enhancing the concrete's resistance. In conclusion, the addition of melt extract stainless steel fiber to concrete significantly improves its resistance to chemical attack. These fibers' corrosion resistance, durability, and high melting point make them an effective reinforcement against aggressive substances, enhancing the concrete's overall durability and lifespan.

- Q: Can melt extract stainless steel fiber be used in architectural concrete?

- Indeed, melt extract stainless steel fiber is a viable option for incorporating into architectural concrete. Its utilization is widespread in architectural concrete projects owing to its impressive strength and durability. By reinforcing the concrete, it aids in bolstering its resistance against cracking, shrinkage, and impact, thereby augmenting the overall performance and lifespan of the structures. Moreover, the inclusion of melt extract stainless steel fiber in architectural concrete also fortifies its resistance against corrosion, rendering it suitable for implementation in architectural endeavors that face exposure to harsh environmental conditions. In summary, the integration of melt extract stainless steel fiber into architectural concrete not only enhances its structural integrity but also elevates its aesthetic allure.

- Q: What is the effect of melt extract stainless steel fiber on the modulus of rigidity of concrete?

- The effect of melt extract stainless steel fiber on the modulus of rigidity of concrete is generally positive. Stainless steel fibers are added to concrete to improve its mechanical properties, including the modulus of rigidity. The modulus of rigidity, also known as shear modulus or G, measures the stiffness of a material. It represents the ability of a material to resist deformation under shear stress. By reinforcing concrete with melt extract stainless steel fibers, the modulus of rigidity is increased, leading to a more rigid and durable concrete structure. Stainless steel fibers act as reinforcement within the concrete matrix, providing additional strength and enhancing the overall performance of the material. These fibers increase the tensile strength and crack resistance of concrete, preventing the propagation of cracks and enhancing its ability to withstand external loads and stresses. The incorporation of melt extract stainless steel fibers also improves the flexural strength of concrete, allowing it to withstand bending forces without failure. This, in turn, contributes to the overall rigidity of the concrete structure. Moreover, the stainless steel fibers help to distribute the applied loads more evenly throughout the concrete, reducing localized stress concentrations. This results in a more uniform distribution of forces, enhancing the overall modulus of rigidity. Overall, the addition of melt extract stainless steel fibers positively impacts the modulus of rigidity of concrete, leading to a stronger and more durable material. The enhanced rigidity and mechanical properties make it suitable for various applications where high-performance concrete is required, such as in infrastructure projects, industrial flooring, and seismic-resistant structures.

- Q: What is the recommended testing procedure for melt extract stainless steel fiber in concrete?

- The recommended testing procedure for melt extract stainless steel fiber in concrete typically involves conducting a series of tests to evaluate its performance and compatibility. This may include evaluating the fiber's physical properties, such as diameter, length, and aspect ratio, through microscopic analysis. Additionally, assessing the fiber's tensile strength, corrosion resistance, and bond strength with concrete is crucial. Various standardized tests, such as ASTM C1550 and ASTM C1609, can be employed to determine these characteristics. Lastly, it is important to conduct field trials to observe the fiber's performance in real-world conditions and ensure its suitability for the intended application.

- Q: The heavy steel fiber feifanshi supeiflat floor for what?

- A production or storage center with higher load requirements

- Q: How does melt extract stainless steel fiber contribute to the fatigue behavior of concrete?

- Melt extract stainless steel fiber enhances the fatigue behavior of concrete by improving its resistance to cracking and increasing its durability. The fibers act as reinforcement, dispersing tensile stresses and reducing the formation of microcracks, thus enhancing the overall fatigue strength of the concrete.

- Q: Can melt extract stainless steel fiber be used in bridge construction?

- Yes, melt extract stainless steel fiber can be used in bridge construction. These fibers provide enhanced strength and durability to the concrete used in the construction of bridges, making them more resistant to cracks and corrosion. Additionally, the stainless steel composition of these fibers helps improve the overall performance and longevity of the bridge structure.

- Q: How is the dosage of melt extract stainless steel fiber determined for concrete reinforcement?

- The dosage of melt extract stainless steel fiber for concrete reinforcement is determined based on various factors including the specific project requirements, the type of concrete being used, and the desired properties of the reinforced concrete. The dosage of stainless steel fiber is typically determined by conducting extensive testing and analysis to ensure that the reinforced concrete meets the desired performance criteria. The dosage is usually expressed in terms of weight or volume percentage of stainless steel fiber relative to the total weight or volume of the concrete. The first step in determining the dosage is to evaluate the specific project requirements such as the design strength, durability, and crack resistance of the concrete. This information helps in identifying the necessary properties that the stainless steel fiber should provide to the concrete. Next, laboratory testing is conducted to assess the compatibility between the stainless steel fiber and the concrete mix. This includes evaluating the fiber's bonding characteristics, dispersibility, and its effect on the fresh and hardened properties of the concrete. The dosage is adjusted based on the results of these tests to optimize the performance of the reinforced concrete. Furthermore, the type of concrete being used also plays a role in determining the dosage. Different concrete mixes have different characteristics, such as different aggregate sizes, water-cement ratios, and admixtures. These factors can influence the dosage of stainless steel fiber required to achieve the desired properties. In addition, the desired properties of the reinforced concrete, such as flexural strength, impact resistance, and crack control, also influence the dosage. Higher dosages of stainless steel fiber are generally required for applications that demand superior performance in terms of these properties. It is important to note that the dosage of stainless steel fiber should be carefully determined to avoid any negative effects on the workability of the concrete mix. Excessive dosages can lead to difficulties in placing and finishing the concrete, as well as potential segregation or balling of the fiber. In summary, the dosage of melt extract stainless steel fiber for concrete reinforcement is determined through a comprehensive analysis of project requirements, concrete mix characteristics, and desired properties of the reinforced concrete. Extensive testing and evaluation are conducted to optimize the dosage and ensure that the stainless steel fiber effectively enhances the performance of the concrete.

Send your message to us

Melt Extract Stainless Steel Fiber End Hook Glued Steel Fiber from CNBM China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords