Melt Extract Stainless Steel Fiber - Copper Coated Steel Fiber from China NBM Company

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Shandong, China (Mainland)

Brand Name: cnbm

Model Number: GW-F

Material: Steel

Specifications

Such steel fiber using the technology into a row of single steel fiber bonding with water-soluble glue, to ensure that the steel fiber uniformly dispersed in concret, easily stirred, eliminate agglomerate phenomena such as, due to the bonding of steel fiberrows technology, steel fibers in concrete can be evenly distributed, so that the concrete structure by the impact of steel fibers can absorb impact energy, reduce stress concentration, effectively control the emergence and development of cracks in the concrete, to extend the structural life.

As reliable and efficient concrete reinforcement material, it is widely uesd in buildings, bridges, thin roof engineering, highway etc.

In bonding steel fiber concrete internal steel fiber, as long as ramming close-grained, and air separation, steel fiber generally don't happen corrosion phenomena. Dew in the concrete surface or in the crack width more than 0.25 mm, jumper cracks in the steel fiber, vulnerable to corrosion phenomena.

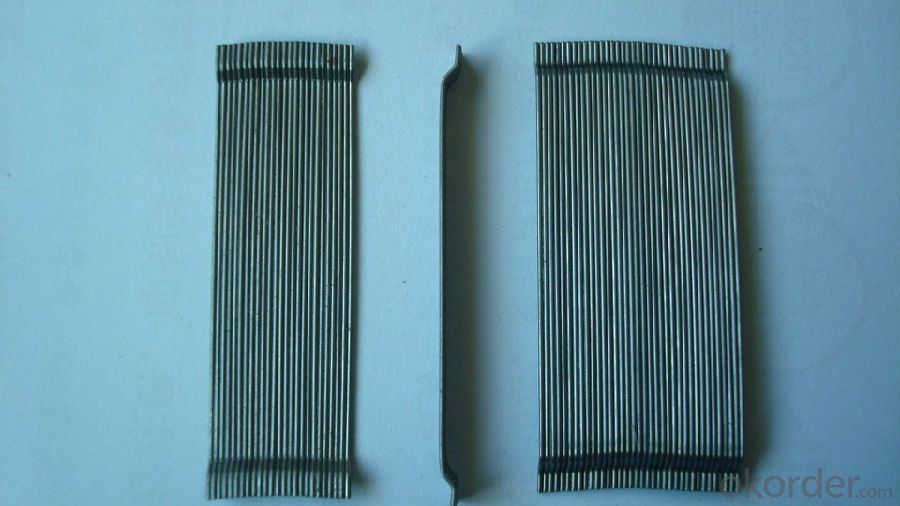

Picture

Steel fiber

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: How does melt extract stainless steel fiber improve the toughness of fiber-reinforced shotcrete?

- The toughness of fiber-reinforced shotcrete can be greatly improved by the addition of melt extract stainless steel fiber, thanks to its unique properties and characteristics. By adding these stainless steel fibers to shotcrete, the overall performance and durability of the concrete are enhanced, resulting in increased tensile and flexural strength. The primary reason why melt extract stainless steel fiber improves the toughness of fiber-reinforced shotcrete is its ability to resist cracking and control crack propagation. Shotcrete is susceptible to cracking under various stress conditions, such as shrinkage, thermal changes, or external forces. These cracks can weaken the structure and compromise its integrity. However, incorporating stainless steel fibers acts as reinforcement, creating a three-dimensional network within the shotcrete matrix. The steel fibers act as micro-reinforcement, helping to distribute the stress load more evenly throughout the concrete. This redistribution of stress effectively minimizes the formation and propagation of cracks. The fibers also act as bridging elements, preventing cracks from widening and spreading further. This improved crack control significantly enhances the toughness of the shotcrete, making it more resilient to external forces and reducing the risk of failure. Moreover, melt extract stainless steel fibers possess excellent corrosion resistance properties, which is crucial for shotcrete applications in aggressive environments or structures exposed to moisture and chemicals. Unlike other types of fibers, such as carbon or polypropylene, stainless steel fibers do not degrade over time due to corrosion. This ensures the long-term durability and performance of the fiber-reinforced shotcrete, even in challenging conditions. Furthermore, the high aspect ratio and small diameter of melt extract stainless steel fibers result in a high surface area, enabling better bonding with the shotcrete matrix. This improved bond strength between the fibers and the concrete further enhances the toughness and overall mechanical properties of the shotcrete. In conclusion, melt extract stainless steel fiber enhances the toughness of fiber-reinforced shotcrete by controlling crack formation and propagation, improving bond strength, and providing excellent corrosion resistance. These properties make it an ideal choice for reinforcing shotcrete in various construction applications, including tunnels, bridges, slope stabilization, and structural repairs.

- Q: What is the effect of melt extract stainless steel fiber on the compressive strength of concrete?

- The inclusion of melt extract stainless steel fiber in concrete has a positive effect on its compressive strength. The fibers enhance the overall toughness and resistance of the concrete by improving its ability to withstand compressive forces. This results in a stronger and more durable concrete structure.

- Q: Is melt extract stainless steel fiber compatible with different types of shotcrete curing methods?

- Different types of shotcrete curing methods can be effectively used with melt extract stainless steel fiber. This fiber type is commonly employed in shotcrete applications to enhance the strength, durability, and ductility of the concrete. It can be incorporated into the shotcrete mix and applied to various surfaces using wet or dry techniques. Melt extract stainless steel fiber offers compatibility with a range of shotcrete curing methods, including standard wet curing, accelerated curing, and polymer-based curing. Its utilization aids in the reduction of cracking and shrinkage in shotcrete, leading to improved overall performance and longevity. Moreover, melt extract stainless steel fiber displays high resistance to corrosion and can endure harsh environmental conditions. This quality renders it suitable for employment in diverse shotcrete curing methods. Its excellent bonding with the concrete matrix enhances structural integrity, impact resistance, and abrasion resistance. In conclusion, melt extract stainless steel fiber is compatible with various types of shotcrete curing methods and has the potential to significantly enhance the performance and durability of shotcrete applications.

- Q: How does the addition of melt extract stainless steel fiber affect the setting time of concrete?

- The addition of melt extract stainless steel fiber can affect the setting time of concrete in a few ways. Firstly, the stainless steel fibers can act as nucleation sites for the formation of hydration products, which can accelerate the setting time of concrete. This is because the stainless steel fibers provide additional surface area for the hydration reactions to occur, leading to faster cement hydration and setting. Secondly, the stainless steel fibers can also improve the overall mechanical properties of the concrete, such as its tensile strength and crack resistance. This can indirectly affect the setting time of concrete by reducing the need for extended curing periods. With improved mechanical properties, the concrete can reach its desired strength faster, allowing for shorter setting times. However, it is important to note that the addition of melt extract stainless steel fiber should be carefully controlled to avoid any negative effects on the setting time of concrete. Excessive amounts of fibers can hinder the flowability of the concrete mixture, leading to longer setting times. Therefore, it is crucial to find the right dosage of stainless steel fibers to achieve the desired setting time and mechanical properties of the concrete. Additionally, the specific characteristics of the stainless steel fibers, such as their length and aspect ratio, can also influence the setting time of concrete and should be taken into consideration during the design and mixing process.

- Q: Does melt extract stainless steel fiber improve the ductility of concrete?

- Concrete can have improved ductility by incorporating melt extract stainless steel fiber. The addition of stainless steel fibers enhances the flexural strength and toughness of concrete. These fibers function as reinforcement within the concrete matrix, forming a network that aids in stress distribution and inhibiting crack propagation. This reinforcement enhances concrete's capacity to deform and absorb energy prior to failure, ultimately enhancing its ductility. Furthermore, stainless steel fibers possess high tensile strength and corrosion resistance, thereby further augmenting concrete's improved ductility.

- Q: Can melt extract stainless steel fiber be used in water retaining structures?

- Yes, melt extract stainless steel fiber can be used in water retaining structures. This type of fiber is highly corrosion-resistant and can withstand exposure to water without compromising its performance. It can be incorporated into concrete or other materials used in water retaining structures to enhance their strength, durability, and crack resistance.

- Q: Can melt extract stainless steel fiber be used in lightweight or low-density concrete?

- Yes, melt extract stainless steel fiber can be used in lightweight or low-density concrete.

- Q: How does melt extract stainless steel fiber improve the bond strength of shotcrete?

- Melt extract stainless steel fiber improves the bond strength of shotcrete in several ways. Firstly, the steel fibers act as reinforcement within the shotcrete mix, providing additional strength to the material. When the shotcrete is applied, the fibers are evenly distributed throughout the mix, creating a network of reinforcement that enhances the overall bond strength. Secondly, the stainless steel fibers have a high aspect ratio, meaning they are long and thin. This characteristic allows them to effectively bridge any cracks or voids that may form within the shotcrete. By bridging these gaps, the fibers prevent the propagation of cracks and enhance the overall cohesion of the material, thus increasing the bond strength. Furthermore, the stainless steel fibers also improve the durability of shotcrete. Due to their corrosion resistance properties, they can withstand harsh environments and prevent degradation over time. This durability ensures that the bond strength of the shotcrete remains intact for an extended period, even in challenging conditions. Overall, melt extract stainless steel fiber enhances the bond strength of shotcrete by providing reinforcement, bridging cracks, and increasing durability. This makes shotcrete more reliable and effective in various construction applications, such as tunnel linings, retaining walls, and structural repairs.

- Q: Does melt extract stainless steel fiber improve the fire resistance of reinforced concrete slabs?

- Yes, melt extract stainless steel fiber can improve the fire resistance of reinforced concrete slabs. Stainless steel fibers are known for their high melting point and excellent thermal conductivity, making them effective in enhancing the fire resistance of concrete structures. When added to concrete, these fibers create a three-dimensional network within the material, providing increased resistance to cracking and spalling during exposure to high temperatures. This reinforcement helps to maintain the structural integrity of the concrete slab and prevents it from crumbling under fire conditions. Additionally, stainless steel fibers also act as a heat sink, absorbing and dissipating heat away from the concrete, further reducing the risk of fire damage. Overall, the incorporation of melt extract stainless steel fibers into reinforced concrete slabs can significantly enhance their fire resistance and improve the overall safety of the structure.

- Q: Does melt extract stainless steel fiber affect the electrical conductivity of concrete?

- Yes, melt extract stainless steel fiber does affect the electrical conductivity of concrete. The addition of stainless steel fibers increases the electrical conductivity of concrete due to the conductive nature of stainless steel. This can be advantageous in applications where electrical conductivity is desired, such as in grounding systems or electromagnetic shielding.

Send your message to us

Melt Extract Stainless Steel Fiber - Copper Coated Steel Fiber from China NBM Company

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords