Melt Extract Stainless Steel Fiber - Steel Fiber Copper Coated from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

1. Material: low carbon steel wire or stainless steel

2.Diameter: 0.4mm-1.0mm

3.Length: meet your requirements

4.tensile strength >1000Mpa

6.Feature: excellent tensile,high tenacity,against cracking,impact and fatigue

7.Uses: highway road surface,tunnel,building,airport road surface and so on .

Straight Steel Fiber

1.ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

Such steel fiber using the technology into a row of single steel fiber bonding with water-soluble glue, to ensure that the steel fiber uniformly dispersed in concret, easily stirred, eliminate agglomerate phenomena such as, due to the bonding of steel fiberrows technology, steel fibers in concrete can be evenly distributed, so that the concrete structure by the impact of steel fibers can absorb impact energy, reduce stress concentration, effectively control the emergence and development of cracks in the concrete, to extend the structural life.

As reliable and efficient concrete reinforcement material, it is widely uesd in buildings, bridges, thin roof engineering, highway etc.

In bonding steel fiber concrete internal steel fiber, as long as ramming close-grained, and air separation, steel fiber generally don't happen corrosion phenomena. Dew in the concrete surface or in the crack width more than 0.25 mm, jumper cracks in the steel fiber, vulnerable to corrosion phenomena.

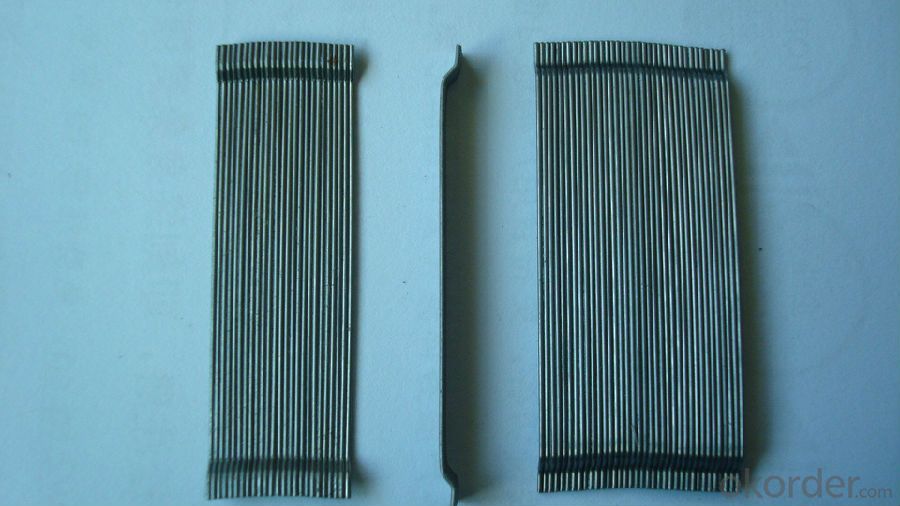

Picture

Steel fiber

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: How does the addition of melt extract stainless steel fiber impact the flowability of concrete?

- The addition of melt extract stainless steel fiber can significantly impact the flowability of concrete. Stainless steel fibers are typically added to concrete to enhance its mechanical properties, such as increasing its tensile and flexural strength, improving its durability, and reducing cracking. However, the addition of stainless steel fibers can also affect the flowability of the concrete mixture. The presence of fibers in the concrete can increase its viscosity, making it more resistant to flow. This can be particularly noticeable in high fiber volume concrete mixtures. The flowability of concrete is commonly measured using the slump test, which measures the consistency and workability of the concrete. When stainless steel fibers are added, the slump of the concrete can decrease, indicating a reduction in flowability. Nevertheless, the impact of stainless steel fibers on flowability can be controlled and managed through proper mix design and dosage. By adjusting the fiber content, the size and shape of the fibers, and the water-to-cement ratio, the flowability of the concrete can be optimized to meet the specific requirements of the project. In conclusion, the addition of melt extract stainless steel fibers can have a noticeable impact on the flowability of concrete. However, with proper mix design and dosage, the flowability can be controlled and adjusted to achieve the desired performance characteristics of the concrete.

- Q: How does melt extract stainless steel fiber improve the resistance of concrete to impact loads?

- Melt extract stainless steel fiber improves the resistance of concrete to impact loads in several ways. Firstly, the addition of stainless steel fibers to concrete significantly enhances its tensile strength and ductility. These fibers act as a reinforcement, distributing the applied load more evenly throughout the concrete matrix and reducing the concentration of stress points. This helps to prevent the formation and propagation of cracks, increasing the overall resistance of the concrete to impact loads. Moreover, the unique properties of stainless steel, such as high strength, corrosion resistance, and durability, contribute to the improved impact resistance of concrete. Stainless steel fibers are extremely tough and can withstand high impact forces without breaking or deforming. This toughness allows them to effectively absorb and dissipate energy during impact, preventing the occurrence of catastrophic failure. Additionally, the small size and high aspect ratio of melt extract stainless steel fibers promote better bonding between the fibers and the concrete matrix. This strong bond ensures that the fibers remain well-anchored within the concrete, even under high impact loads. This, in turn, increases the overall strength and integrity of the concrete, making it more resistant to impact-induced damage. Furthermore, the addition of stainless steel fibers can also enhance the post-cracking behavior of concrete. When cracks do occur due to impact loads, the fibers help to hold the cracked sections together, preventing further separation and limiting the extent of damage. This post-cracking behavior contributes to the overall improvement in the resistance of concrete to impact loads. In summary, melt extract stainless steel fiber improves the resistance of concrete to impact loads by enhancing its tensile strength, ductility, and toughness. The fibers contribute to a more even distribution of applied loads and prevent the formation and propagation of cracks. Their strong bond with the concrete matrix and ability to absorb and dissipate energy during impact further enhance the impact resistance of the concrete.

- Q: Can melt extract stainless steel fiber be used in marine environments?

- Yes, melt extract stainless steel fiber can be used in marine environments. Stainless steel is known for its excellent corrosion resistance, making it suitable for various applications in marine environments. The melt extract stainless steel fibers are produced using a special process that ensures high tensile strength and durability, making them capable of withstanding the harsh conditions found in marine environments, such as saltwater exposure and high moisture levels. These fibers can be used in various marine applications, including reinforcement of concrete structures, marine coatings, and marine composites, to provide enhanced durability and corrosion resistance.

- Q: Is melt extract stainless steel fiber suitable for use in high-performance mortar?

- Yes, melt extract stainless steel fiber is suitable for use in high-performance mortar. It enhances the mechanical properties and durability of the mortar, providing increased flexural and impact strength, as well as improved resistance to cracking, shrinkage, and corrosion.

- Q: Can melt extract stainless steel fiber be used in thin concrete overlays?

- Yes, melt extract stainless steel fiber can be used in thin concrete overlays. These fibers are typically added to concrete mixes to enhance their mechanical properties and improve their durability. In thin concrete overlays, where the thickness of the concrete layer is less than 2 inches, the use of stainless steel fibers can help to reduce cracking and increase resistance to shrinkage and impact. The fibers provide additional reinforcement and improve the overall performance of the concrete overlay. However, it is important to ensure that the correct dosage of fibers is used and that they are evenly distributed throughout the mix to achieve optimal results. Additionally, proper surface preparation and application techniques are crucial to ensure the successful use of melt extract stainless steel fiber in thin concrete overlays.

- Q: Can melt extract stainless steel fiber be used in architectural precast concrete applications?

- Architectural precast concrete applications can benefit from the utilization of melt extract stainless steel fiber. It is a common practice to incorporate stainless steel fibers into concrete mixes in order to enhance the overall strength, durability, and performance of the final product. By utilizing stainless steel fibers in architectural precast concrete, the structural integrity of the panels can be improved, making them more resistant to cracking, impact, and other types of damage. Moreover, the implementation of stainless steel fibers in architectural precast concrete can enhance the visual appeal of the panels by reducing surface defects and improving the overall finish. These fibers also offer additional reinforcement to the concrete, allowing for thinner and lighter panels without compromising strength. Melt extract stainless steel fibers are particularly well-suited for architectural precast concrete applications due to their high tensile strength, corrosion resistance, and ability to withstand extreme temperatures. These fibers are manufactured using a specialized process that guarantees consistent quality and performance. In conclusion, incorporating melt extract stainless steel fiber in architectural precast concrete applications is highly recommended as it can significantly enhance the durability, strength, and aesthetics of the panels.

- Q: The steel fiber concrete cover per cubic concrete how much steel fiber

- After buying the equipment, they provided us with a recipe ratio.

- Q: Can melt extract stainless steel fiber be used in self-compacting concrete (SCC)?

- Indeed, melt extract stainless steel fibers are capable of being utilized in self-compacting concrete (SCC). SCC, a type of concrete that possesses high fluidity and is able to occupy and flow into even the most densely packed reinforcement areas without the need for vibration, often incorporates stainless steel fibers to augment its mechanical characteristics, including flexural strength, impact resistance, and toughness. The production of melt extract stainless steel fibers involves a melt extraction process, which guarantees consistent quality and uniform dispersion of fibers within the concrete matrix. These fibers exhibit exceptional resistance to corrosion and possess outstanding durability, rendering them suitable for employment in SCC, which is frequently employed in the construction of high-performance and long-lasting concrete structures. The inclusion of melt extract stainless steel fibers in SCC yields improvements in its ductility, crack resistance, and overall performance. These fibers function as reinforcement, supplying supplementary tensile strength to the concrete and diminishing the likelihood of cracking. Additionally, they aid in the control of shrinkage and the prevention of plastic shrinkage cracks. Moreover, melt extract stainless steel fibers contribute to the post-cracking behavior of SCC by heightening its resistance to cracking and ensuring the integrity of the concrete even subsequent to cracking. This is especially advantageous in scenarios where the control of cracks and the preservation of structural integrity are of utmost importance, such as in industrial flooring, tunnel linings, and precast elements. To summarize, melt extract stainless steel fibers can be effectively employed in self-compacting concrete (SCC) to enhance its mechanical properties, enhance crack resistance, and ensure long-term durability. The inclusion of these fibers in SCC can result in the creation of sturdier and more enduring concrete structures, rendering them a fitting choice for a variety of construction applications.

- Q: Does melt extract stainless steel fiber improve the resistance to sulfate attack of shotcrete?

- Yes, melt extract stainless steel fiber does improve the resistance to sulfate attack of shotcrete.

- Q: How does melt extract stainless steel fiber affect the curing process of concrete?

- Melt extract stainless steel fiber has a significant impact on the curing process of concrete. When added to the concrete mixture, these fibers distribute uniformly throughout the mixture, providing reinforcement and enhancing the overall strength and durability of the cured concrete. The stainless steel fibers act as a reinforcement material, improving the flexural strength, toughness, and resistance to cracking of the concrete. This reinforcement effect is particularly beneficial in reducing early-age cracking, plastic shrinkage cracking, and drying shrinkage cracking, which commonly occur during the curing process. Moreover, the stainless steel fibers improve the bond between the cement paste and the aggregates, preventing internal micro-cracking and enhancing the concrete's ability to withstand stresses and loads. This enhanced bond also reduces the risk of delamination and spalling, thereby increasing the durability and longevity of the cured concrete. Additionally, melt extract stainless steel fibers help to control the formation and propagation of cracks in the concrete. By bridging the cracks, these fibers restrict their width and limit their growth, thus minimizing the potential for structural failure and increasing the concrete's ability to withstand external forces. Furthermore, the stainless steel fibers aid in the control of plastic shrinkage and settlement cracking by reducing the water evaporation rate from the concrete surface. This slower drying process allows for a more controlled and uniform curing, resulting in improved overall strength and reduced permeability of the concrete. In summary, the addition of melt extract stainless steel fibers to concrete significantly affects the curing process by enhancing the concrete's strength, durability, resistance to cracking, and overall performance. These fibers provide reinforcement, improve bond strength, control crack formation, and reduce shrinkage, ultimately resulting in a higher quality and longer-lasting cured concrete.

Send your message to us

Melt Extract Stainless Steel Fiber - Steel Fiber Copper Coated from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords