96 Inch Marble Finish Wood Surface Stone Vein Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Marble Finish Wood Surface Stone Vein Aluminum Coil

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

2. Application of Marble Finish Wood Surface Stone Vein Aluminum Coil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Marble Finish Wood Surface Stone Vein Aluminum Coil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

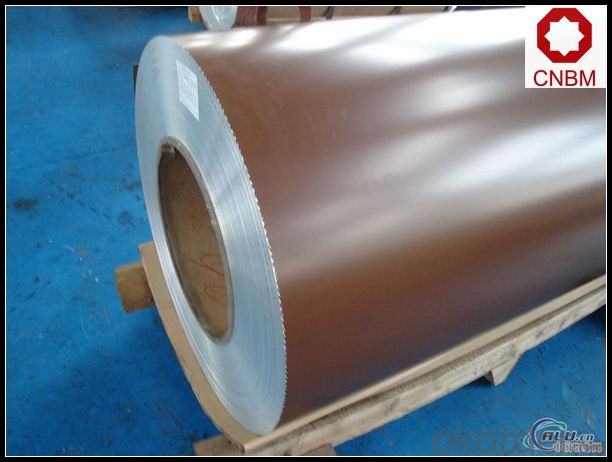

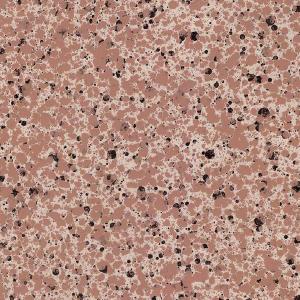

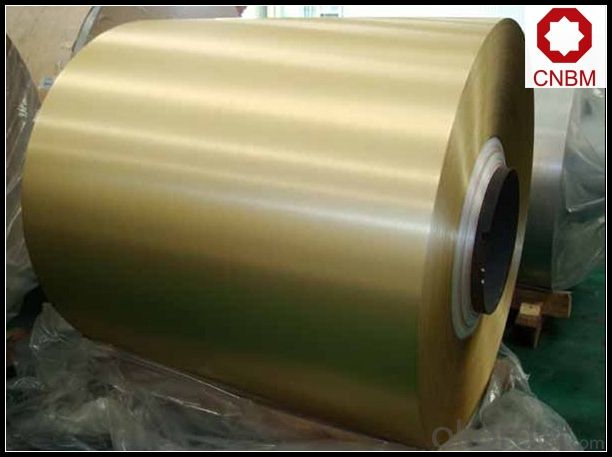

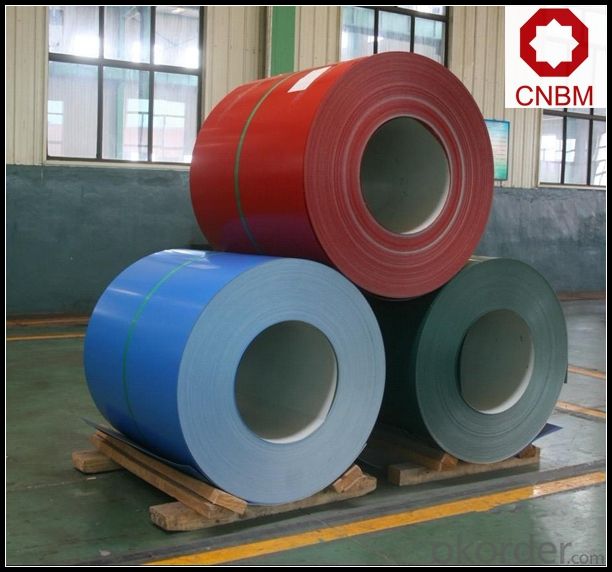

5. Image of Marble Finish Wood Surface Stone Vein Aluminum Coil

6. Package and shipping of Marble Finish Wood Surface Stone Vein Aluminum Coil

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Who knows the color coated aluminum roll, that is, roll coating manufacturers? Yes, let me know!

- I don't know if there are any regional restrictions. The ones over there in Guangdong are pretty clear. Just like Jadali, new Korea and force equal, those are good.

- Q: Can aluminum coils be customized?

- Indeed, it is possible to customize aluminum coils to meet specific requirements. These coils possess remarkable versatility, as they can be tailored in terms of thickness, width, length, alloy composition, surface finish, and other specifications. Consequently, they find extensive utility across diverse industries, including construction, automotive, aerospace, electronics, and packaging. The customization of aluminum coils involves various processes, such as slitting, cutting-to-length, embossing, painting, and coating. This remarkable flexibility in customization empowers manufacturers to satisfy the distinct demands of their clientele, thereby ensuring that the aluminum coils are perfectly optimized for their intended applications.

- Q: What are the steps to properly store an unused aluminum coil to prevent it from rusting?

- <p>To store an unused aluminum coil and prevent rusting, follow these steps: 1. Clean the coil thoroughly to remove any dirt or moisture. 2. Apply a thin layer of a rust inhibitor or light oil to the surface. 3. Wrap the coil in a protective plastic or wax paper to prevent moisture and air exposure. 4. Store the coil in a cool, dry place away from direct sunlight and humidity. 5. Ensure the storage area is well-ventilated to prevent condensation. 6. Periodically check the coil for any signs of rust and clean if necessary. By following these steps, you can effectively prevent rusting and maintain the quality of the aluminum coil.</p>

- Q: How are aluminum coils used in the production of architectural panels?

- Aluminum coils play a crucial role in the production of architectural panels by serving as the primary material for their construction. These coils are typically made from high-quality aluminum alloy, which possesses several desirable characteristics such as lightweight, corrosion resistance, and malleability. The first step in using aluminum coils for architectural panels involves uncoiling the raw material. The coils are unwound and flattened to create flat sheets of aluminum. These sheets are then cut to the desired size and shape, depending on the specific architectural panel design requirements. Once the aluminum sheets are prepared, various manufacturing techniques can be used to further process them. These techniques include bending, folding, welding, and punching to achieve the desired panel shape and functionality. The malleability of aluminum allows for precise shaping and customization, making it an ideal material for architectural panel production. Additionally, aluminum coils can be coated or treated to enhance their appearance, durability, and performance. Coatings such as paint, powder coating, and anodizing can be applied to the aluminum surface to provide protection against weathering, UV radiation, and corrosion. These coatings can also offer aesthetic options, allowing architects and designers to choose from a wide range of colors and finishes for their architectural panels. Architectural panels manufactured using aluminum coils offer numerous benefits. Firstly, due to the lightweight nature of aluminum, these panels are easier to handle and install, reducing labor costs and time. Additionally, aluminum's corrosion resistance ensures that architectural panels remain durable and visually appealing even in harsh weather conditions. The malleability of aluminum also allows for intricate designs and complex shapes, enabling architects to create visually striking and unique building facades. In conclusion, aluminum coils are an essential component in the production of architectural panels. Their lightweight, corrosion resistance, and malleability properties make them an ideal material for creating durable and aesthetically pleasing panels. Whether it is for high-rise buildings, residential homes, or commercial structures, aluminum coils are instrumental in the production of architectural panels that enhance the visual appeal and functionality of modern architecture.

- Q: What is the common color of aluminum coil membrane?

- The blue transparent membrane is the most common.

- Q: What are the differences among various types of steel wires and their respective coiling techniques?

- <p>Yes, there are differences between different types of steel wires and their coiling methods. Steel wires can be categorized based on their composition, strength, and use, such as carbon steel, stainless steel, and alloy steel wires. Each type has unique properties that affect their coiling methods. For instance, carbon steel wires are strong and ductile, suitable for standard coiling techniques, while stainless steel wires offer corrosion resistance and may require special handling to prevent damage. The coiling methods also vary; some common ones include spool coiling, loop coiling, and pancake coiling. Each method has specific applications and considerations for wire diameter, tension, and storage. Understanding these differences is crucial for selecting the appropriate wire and coiling technique for a given application.</p>

- Q: Are aluminum coils suitable for heat sinks?

- Yes, aluminum coils are suitable for heat sinks. Aluminum is a popular choice for heat sinks due to its excellent thermal conductivity and low cost. The high thermal conductivity of aluminum allows it to efficiently transfer heat away from a heat source towards the fins of the heat sink, where it can be dissipated into the surrounding environment. Additionally, aluminum is lightweight and easily formed into various shapes, making it a versatile material for heat sink applications. Overall, aluminum coils are a suitable choice for heat sinks, providing effective heat dissipation and cost-effectiveness.

- Q: I think the use of aluminum, at the lower levels, has really hurt US born players. To give a kid a piece of metal, and expect him to use wood when drafted........ I think US should go back to wood, whatever the costs (I know the aluminum is far cheaper). Thoughts....Cheers.

- Maybe. Remember, there are still tons of American born players who are some of the top players in the league. Mark Teixeira, David Wright, Ryan Braun, and many others. Also, while the use of aluminum bats may hurt American position players, pitching is completely dominated by Americans. Tim Lincecum, CC Sabathia, Cole Hamels, Ryan Dempster, Jake Peavy, Scott Kazmir. The problem is that like you said aluminum is cheaper and players are used to them. Also with aluminum bats you can have bats as light as 18 ounces and as heavy as 30 or more ounces, so kids can start using aluminum bats from an early age and not want to switch to wood. I think what they should at least do is take aluminum bats out of college baseball.

- Q: How are aluminum coils stored and transported?

- Aluminum coils are typically stored and transported in various ways depending on their size and weight. They are commonly stored in warehouses or outdoor storage facilities, where they are organized and stacked horizontally on pallets or racks. To ensure their protection, coils are often covered with a protective material such as plastic or shrink wrap. When it comes to transportation, aluminum coils are usually loaded onto trucks, containers, or flatbed trailers for long-distance journeys. To prevent damage during transit, the coils are secured using straps, chains, or other fastening methods. Additionally, specialized equipment like coil racks or cradles can be used to provide extra support and stability. Overall, proper storage and transportation practices are crucial to maintain the integrity of aluminum coils and prevent any potential harm.

- Q: This question asks for criteria or methods to determine if a used aluminum coil is safe for reuse.

- <p>To determine if a used aluminum coil is safe to use, consider the following: Check for any visible signs of damage such as cracks, dents, or corrosion. Ensure the coil has been properly cleaned and sanitized to remove any residues or contaminants. Verify that the coil has not exceeded its recommended lifespan or usage limits. Consult the manufacturer's guidelines for any specific safety checks or maintenance requirements. If in doubt, it's best to consult with a professional or replace the coil to avoid potential safety hazards.</p>

Send your message to us

96 Inch Marble Finish Wood Surface Stone Vein Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords