Manhole Cover Ductile Cast Iron Anti Theft EN124 E600

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Cast Iron Manhole Cover Description :

A manhole cover is a removable plate forming the lid over the opening of a manhole, to prevent anyone or anything from falling in, and to keep out unauthorized persons and material.

A manhole cover sits on metal base, with a smaller inset rim which fits the cover. The base and cover are sometimes called "castings", because they are usually made by a casting process, typically sand-casting techniques.

2.Main Features of the Ductile Iron Manhole Cover:

1) Production information

manhole cover are manufactured for construction and public use .Manhole cover shall be smooth and free sand holes , blow holes , distortion or any other defects

2) Material

a) Ductile iron GGG500&400-12

B) Grey iron GG20

3) Designs

a) EN124 Class B125 C250 D400 ,with different size and grammage, or as per customers requirement

b) Major standards designs available

c) as per customers' drawing or samples

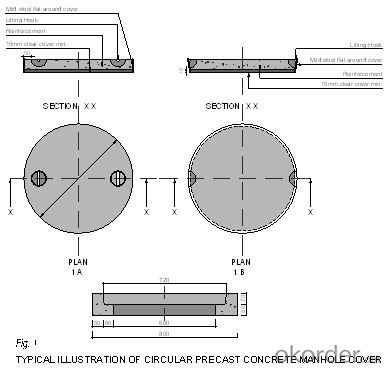

3.Manhole Cover Images:

4.Manhole Cover Specifications:

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

Q. Can I fit a square manhole cover into a round chamber?

A. Yes, there are a select few manhole covers which are square-to-round, meaning they will fit square or round chambers.

Q. I have a heavy traffic manhole cover but it has been broken by a forklift, why?

A. Forklifts have solid wheels which apply pressure differently to standard pneumatics and therefore covers must be specially adapted to suit this.

Q. Odours are coming through where I have installed my manhole cover, why?

A. Your cover must be sealed and locked, or neoprene sealed, so you would require a T-Range Cover, or if you require a solid top, a selection of the PC range (e.g. PC2BG3, PC6CG3, not PC2BG) are suitable.

Q. I need access through my manhole cover on a regular basis, is this possible?

A. Yes, the majority of covers have built-in lifting keys, and for those that don’t we also supply lifting keys. However, the best way to obtain easy access is to have a bespoke, hinged manhole cover.

- Q: Why does the precision casting factory not usually make iron castings?

- The so-called precision parts is the size, roughness requirements of the piece. Cast iron parts generally do not reach the accuracy.

- Q: The casting defects of pores, trachoma how to repair?

- If the repair after the high temperature resistance, choose LT737 high temperature repair agent.

- Q: What is the ejection angle of the die casting (Tan Gang)?

- Especially deep hole, and customers to discuss, generally take 0.3-1 degrees is enough

- Q: Domestic large steel castings factory which is better, recommend!

- Do the casting manufacturer of large steel castings, Hunan Jinsha heavy industry science and technology limited company, heard that their professional only more than 1 tons of steel castings, anyway, 150T just big, the company won a lot of foundry industry patents should be good. At least spend money on research and development, then the quality should be all right.

- Q: Is the cast steel a casting part?

- Yes, molten steel is poured into the mold and cooled to become a casting. Can also cast iron, cast aluminum, plastic casting.

- Q: the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- If it is not directly cast hole hole, later processing, large pores may be directly cast out,

- Q: What's the density of the cast iron? The density is thin and the density is thin

- Uneven casting density is caused by uneven shrinkage of the casting during solidification.

- Q: How to cast iron and wrought iron collocation

- 2, listen: Pig beating sound boring, wrought iron beating sound loud.

- Q: When the blank is a casting, the margin is evenly distributed, how should rough machining?Please help friends from mechanical classes.There is another problem: in the NC milling plane contour machining, when the rough margin is large, how to deal with.Who can help in time, add 20 reward. Urgently!!

- Even distribution is a good thing. Generally, the machining allowance of the casting is uneven.If the processing depends on how your processing techniques have been arranged.In the NC milling plane contour machining, when the rough margin is large, how to deal with.1. Return to the foundry, too large margin improvement.2. Then you can spend more time on it.

- Q: Is 316 casting better than 304 casting?

- It is comprehensive. There is no simple comparison of the material to determine the degree of difficulty in processing

Send your message to us

Manhole Cover Ductile Cast Iron Anti Theft EN124 E600

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords