Ductile Cast Iron Manhole Cover EN124 for Iidustry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

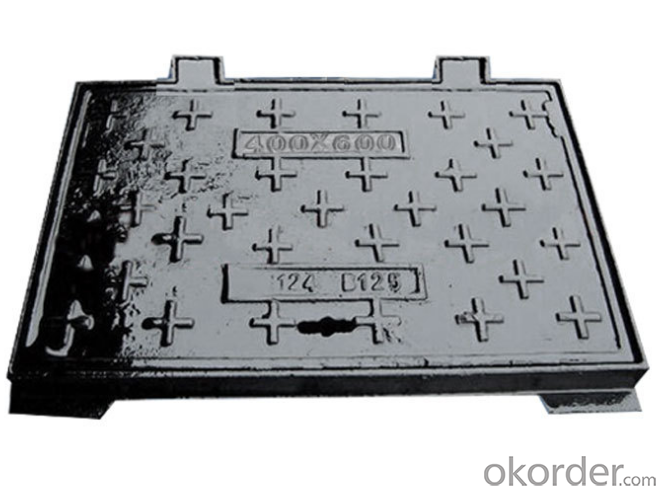

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron

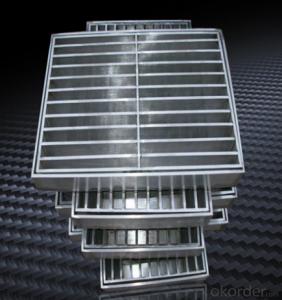

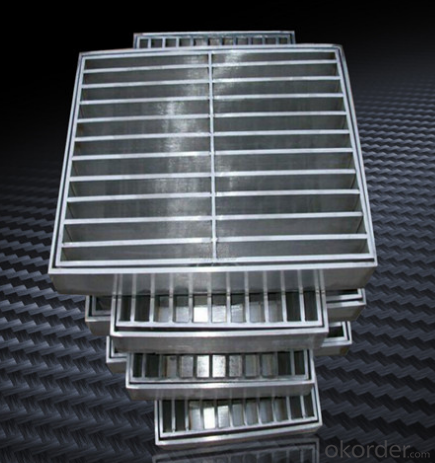

3) Type: round type and Square type, triangle

4) Sand casting

5) we can produce as per customers' drawings

Specification

| Item No. | Class | Clear Opening (mm) | Frame Size(mm) | Frame Height (mm) | Unit Weight (kg/set) |

| D110 | D400 | 1000*1000 | 1100*1100 | 100 | 202 |

| D100 | D400 | 900*900 | 1000*1000 | 100 | 175 |

Advantages

Higher quality /higher tensile

Higher security /long life

Possibilities of new locking systems

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1. Can I get free samples?

A: Yes, we can provide you the free sample, but you need to bear their own delivery costs.

2. Can I request to change the form of packaging and transportation?

A: Yes , We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

- Q: How is the silicon sol precision casting part priced? What is the price per ton of casting? Such as 304 material.

- I am doing this for sale, if the price is mainly based on the product structure, the difficulty of pricing. At present, if it is more formal and material guarantee manufacturers generally in 48-53 yuan /Kg (of course, products have a certain weight, such as greater than 100g), our company's current price of about 53 yuan /Kg or so. .

- Q: What is normalizing, annealing, tempering, quenching? What is the difference between forging parts and casting parts?

- The aim is to make the grain fine and distribute the carbide evenly. The difference between normalizing and annealing is that normalizing cooling rate is slightly faster than annealing cooling rate, so normalizing structure is finer than annealing structure, and its mechanical properties are also improved. In addition, normalizing furnace cooling does not occupy equipment and has higher productivity. Therefore, normalizing may be used instead of annealing as much as possible. The main application areas of normalizing are as follows: for low carbon steel, after normalizing, the hardness is slightly higher than that of annealing, and the toughness is better. It can be used as the pretreatment of cutting. Used for medium carbon steel, instead of quenching and tempering, as the final heat treatment, or as an induction heating method before surface hardening. Used for tool steel, bearing steel, carburizing steel, etc., it can eliminate or restrain the formation of network carbide, so as to obtain the good organization of spheroidizing annealing. For cast steel, the microstructure can be refined and the machinability can be improved. Used for large forgings, which can be used as final heat treatment, so as to avoid larger cracking tendency during quenching.

- Q: What's the effect of casting copper?

- In general cast iron, the mass fraction of copper below 3% - 3.5% can increase the hardness; but when the cast iron has a tendency to chill, or when there is a hard point of free carbides, the addition of copper decreases the hardness.Copper can be used to improve the wear resistance, abrasion resistance, and shock absorption of cast iron, so it is often used in the manufacture of sliding friction iron castings, such as drilling machine spindle, automobile and tractor, valve tappet, etc.. But in white cast iron or chilled cast iron, adding copper does not make any improvement in its abrasion resistance.Copper for certain heat resistant cast iron and austenitic cast iron can increase the heat resistance and corrosion resistance, copper - chromium composite alloy to prevent oxidation under high temperature in the atmosphere from the skin effect is particularly effective, heat resistance and corrosion resistance of austenitic cast iron containing many mass fraction of 4% ~ 7% copper.

- Q: How to get rid of casting sand inside casting parts?

- Are you saying that in the sand casting cavity? We use the manual blast, he is like a pipe will be automatic shot out of the grit, into the casting cavity, to remove the internal cavity in the purpose of casting sand!

- Q: Casting parts have poor surface finish. What sand is used to make them?

- Manual coal dust, clay sand is a little worse. Mechanical styling is not bad either.

- Q: After reaming, the roughness can reach several levels, that is to say, the sample.Casting parts in rocker arm drilling, reaming, roughness, block. After reaming, the roughness can reach several levels, that is to say, the sample.

- Radial drilling machine can achieve boring, reaming function, but as much as you want, according to your requirements and material to determine!

- Q: What do you mean by "proofing" in the casting? Do you charge for the proofing?

- Proofing refers to making the first sample to confirm to the customer

- Q: In the design of casting steps and precautions, for casting design, we have what experience?.

- (3) to prevent generating white grey cast iron, in addition to taking measures from the process, must make the wall thickness is not too thin (some sources indicate that the corner wall thickness above 15mm, metal type casting must be in the corner, for Aluminum Alloy, magnesium alloy casting casting casting Create fillet should not be less than 3-4m, for casting round cast iron, copper alloy mould casting can see table 1.1-32 selection; (5) because of the metal and the core without let, for the convenience of the casting is taken out and the draw out type, slope casting casting should be suitably large than sand casting metal casting. General 30%-50%, it should be pointed out that in addition to the height of the slope of casting size and alloy type, wall, is also related to the casting surface position, where the cooling and contraction and metal surface of casting surface can be designed from the tendency of small inclination, while casting shrinkage tend to be pressed on the surface of metal castings the type should be given greater inclination, all kinds of metal type alloy casting casting casting.

- Q: Is 316 casting better than 304 casting?

- The degree of difficulty in the process of casting depends mainly on the structure, precision requirements, and hardness of the casting. It is comprehensive. There is no simple comparison of the material to determine the degree of difficulty in processing

- Q: Shandong foundry, casting small pieces of precision casting

- Dongying Huayang precision casting factory, the smallest to do 2G pieces.

Send your message to us

Ductile Cast Iron Manhole Cover EN124 for Iidustry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches