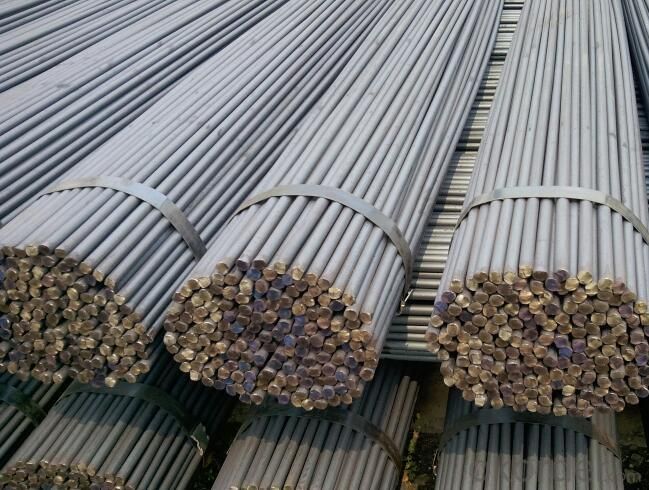

Hot Rolled Prime Low Carbon Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Prime Low Carbon Steel Round Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Prime Low Carbon Steel Round Bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Rolled Prime Low Carbon Steel Round Bar are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

| ROUND BAR | |

| SIZE d(mm) | theoretical kg/m |

| 5.5 | 0.186 |

| 6 | 0.222 |

| 7 | 0.302 |

| 8 | 0.395 |

| 9 | 0.499 |

| 10 | 0.617 |

| 11 | 0.746 |

| 12 | 0.888 |

| 13 | 1.04 |

| 14 | 1.21 |

| 15 | 1.39 |

| 16 | 1.58 |

| 17 | 1.78 |

| 18 | 2 |

| 19 | 2.23 |

| 20 | 2.47 |

| 21 | 2.72 |

| 22 | 2.98 |

| 24 | 3.55 |

| 25 | 3.85 |

| 26 | 4.17 |

| 28 | 4.83 |

| 30 | 5.55 |

| 32 | 6.31 |

| 34 | 7.13 |

| 36 | 7.99 |

| 38 | 8.9 |

| 40 | 9.86 |

| 42 | 10.9 |

| 45 | 12.5 |

| 48 | 14.2 |

| 50 | 15.4 |

| 53 | 17.3 |

| 56 | 19.3 |

| 60 | 22.2 |

| 63 | 24.5 |

| 65 | 26 |

| 70 | 30.2 |

| 75 | 34.7 |

| 80 | 39.5 |

| 85 | 44.5 |

| 90 | 49.9 |

| 95 | 55.6 |

| 100 | 61.7 |

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Q2: what is the difference between actual weight and theoretical weight?

A2: All the section steel has two weights: actual weight and theoretical weight. Actual weight is the weighing out when the product delivered from the mill. Theoretical weight is calculated by pieces. The invoice can be based on each of them as your request

Q3: How many tons of steel products could be loaded in containers?

A3: Usually the steel products are delivered by bulk vessel because of the large quantity and the freight. However, there are no bulk vessel enter some seaports so that we have to deliver the cargo by containers. The 6m steel product can be loaded in 20FT container, but the quantity is changed according to the size, usually from 18tons to 25tons.

Images:

- Q: How are steel round bars classified based on their shape?

- Steel round bars are classified based on their shape as either hot-rolled or cold-drawn round bars.

- Q: What are the advantages of using carbon steel round bars?

- The advantages of using carbon steel round bars include high strength and durability, excellent machinability, and cost-effectiveness. Carbon steel round bars are known for their superior tensile strength, making them suitable for heavy-duty applications. They are also highly resistant to wear and tear, ensuring long-lasting performance. Additionally, carbon steel round bars can be easily shaped and formed, making them ideal for machining processes. Lastly, carbon steel round bars are relatively affordable compared to other materials, providing a cost-effective solution for various industries.

- Q: Can steel round bars be used for making wire?

- Yes, steel round bars can be used for making wire by undergoing a process called wire drawing. In this process, the steel round bar is pulled through a series of progressively smaller dies, reducing its diameter and elongating it into wire form.

- Q: Can steel round bars be used in the construction of buildings?

- Yes, steel round bars can be used in the construction of buildings. They are commonly used as reinforcement materials in concrete structures due to their high strength and durability. Steel round bars provide structural stability and help resist bending and tensile forces, making them an important component in building construction.

- Q: What are the different types of steel round bar surface defects?

- There are several types of steel round bar surface defects, including pits, roll marks, scratches, cracks, scale, and decarburization.

- Q: What is the elasticity of a steel round bar?

- The elasticity of a steel round bar refers to its ability to return to its original shape and size after being subjected to external forces or deformations. Steel is known for its high elastic modulus, which means it has a high resistance to deformation and can withstand substantial stress before permanently bending or breaking. The elasticity of a steel round bar is determined by its composition, specifically the carbon content and the presence of other alloying elements. Steel with higher carbon content is generally more elastic and can be more easily manipulated without permanent deformation. However, it is important to note that the elasticity of a steel round bar can also be affected by factors such as temperature, strain rate, and the presence of any defects or imperfections in the material.

- Q: What are the advantages of using nickel-titanium alloy steel round bars?

- Nickel-titanium (NiTi) alloy steel round bars offer several benefits. Firstly, they possess exceptional shape memory and superelasticity properties. This means that they can be bent or deformed and then return to their original shape when heated or when stress is removed. This unique characteristic makes them perfect for applications requiring flexibility and resilience, such as surgical instruments or orthodontic wires in the medical field. Another advantage of NiTi alloy steel round bars is their high resistance to corrosion. Both nickel and titanium are highly resistant to corrosion, making the alloy extremely durable and long-lasting. This makes them suitable for industrial applications, including marine environments where exposure to moisture and saltwater can cause corrosion in other metals. Additionally, NiTi alloy steel round bars have a high strength-to-weight ratio. Despite being lightweight, they possess excellent mechanical properties, including high tensile strength and good fatigue resistance. This makes them suitable for engineering and structural applications in industries like aerospace, automotive, and construction. The bars' lightweight nature also allows for easier handling and transportation. Moreover, NiTi alloy steel round bars demonstrate excellent thermal stability, with a wide temperature range of usability. They can withstand extreme temperatures without losing their shape memory or superelasticity properties. This makes them suitable for applications involving exposure to high or low temperatures, such as in the aerospace or oil and gas industries. To sum up, the benefits of using NiTi alloy steel round bars include their shape memory and superelasticity properties, high resistance to corrosion, high strength-to-weight ratio, and excellent thermal stability. These qualities make them a versatile and reliable choice for a wide range of applications in various industries.

- Q: What are the advantages of using weather-resistant steel round bars?

- Weather-resistant steel round bars have numerous benefits. Firstly, they are specifically designed to withstand harsh weather conditions, such as corrosion, rust, and degradation caused by rain, snow, humidity, and saltwater environments. This makes them ideal for outdoor applications like construction projects, marine structures, and coastal infrastructure. Secondly, weather-resistant steel round bars eliminate the need for extra protective coatings or treatments. Unlike regular steel, which requires frequent maintenance and painting to prevent rust and corrosion, these bars develop a natural protective layer called patina. This patina acts as a barrier against further corrosion, reducing maintenance requirements and extending the material's lifespan. Thirdly, these bars offer exceptional strength and durability. They are manufactured with a special alloy composition that enhances their mechanical properties, making them highly resistant to impact, bending, and fatigue. This makes them perfect for structural applications in bridges, building frameworks, and heavy machinery. Additionally, weather-resistant steel round bars have aesthetic advantages. The unique patina that forms on their surface gives them an attractive reddish-brown color, adding a visually appealing element to architectural and design purposes. Lastly, the use of weather-resistant steel round bars contributes to sustainability and cost-effectiveness. Their long lifespan and low maintenance requirements make them a more sustainable option compared to traditional steel. While the initial investment may be higher, the long-term savings in maintenance and replacement costs make them a cost-effective choice in the long run. In conclusion, the benefits of using weather-resistant steel round bars include their ability to withstand harsh weather conditions, eliminate the need for additional protective coatings, provide exceptional strength and durability, offer aesthetic appeal, and contribute to sustainability and cost-effectiveness.

- Q: What are the typical yield strengths of different grades of steel round bars?

- The yield strength of steel round bars can vary depending on the specific grade of steel. Here are some typical yield strengths for different grades of steel round bars: - Mild steel round bars typically have a yield strength of around 250 MPa (megapascals) or 36,000 psi (pounds per square inch). - Carbon steel round bars can have a yield strength ranging from 350 to 550 MPa or 50,000 to 80,000 psi. - Alloy steel round bars, such as 4140 or 4340, generally have higher yield strengths compared to mild or carbon steel. The yield strength of these alloys can range from 550 to 850 MPa or 80,000 to 120,000 psi. - Stainless steel round bars come in various grades, and their yield strengths can vary accordingly. For example, austenitic stainless steels like 304 or 316 typically have yield strengths ranging from 200 to 300 MPa or 29,000 to 43,000 psi. On the other hand, duplex stainless steels like 2205 or 2507 can have higher yield strengths ranging from 450 to 650 MPa or 65,000 to 95,000 psi. It is important to note that these values are just typical ranges, and the actual yield strength of a specific grade of steel round bar may differ based on factors such as heat treatment, manufacturing process, and other variables. Therefore, it is always recommended to consult the manufacturer's specifications or industry standards for accurate and precise yield strength values of steel round bars.

- Q: Can steel round bars be used in the production of flanges?

- Flanges in the production process can utilize steel round bars. Steel round bars, commonly used as raw materials, can be machined, forged, or rolled into the desired flange shape. The production of flanges benefits from steel round bars due to their high strength, durability, and resistance to corrosion. Additionally, they can be easily fabricated and machined to meet specific size and dimensional needs. Various industries, including oil and gas, petrochemical, power generation, and construction, widely employ steel round bars for the production of flanges. These flanges are essential in connecting pipes or equipment within piping systems.

Send your message to us

Hot Rolled Prime Low Carbon Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords