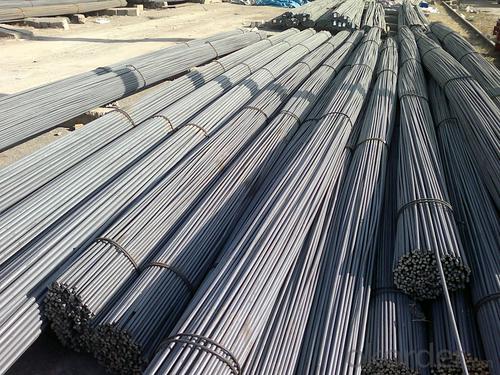

Hot Rolled Steel Round Bar 6mm-150mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Chinese Standard Round Bar

1. Grade: Q195, Q235, Q345

2. Diameter: 6mm-150mm

3. Length: 6m, 9m, 12m or as customer’s request

4. Tolerance: Within ±5% for weight; ±2mm for diameter

5. Note: The price can be better is the quantity is good

6. Chemical composition

Alloy No | Element (%) | ||||

C | Mn | S | P | Si | |

Q195 | 0.06-0.12 | 0.25 | ≤0.05 | ≤0.045 | ≤0.3 |

Q235 | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 |

Q345 | ≤0.2 | 1.00-1.60 | ≤0.045 | ≤0.045 | ≤0.55 |

Usage and Applications of Chinese Standard Round Bar

1. Chinese standard steel bar is often used where large amounts of steel need to be formed, for example as structural steel.

2. And we can use this kind of product on the performance of the mechanical parts if the demand is not very high.

3. Steel round bar is used in construction and a large number of architectural and engineering structures.

Packaging & Delivery of Chinese Standard Round Bar

Packaging Detail: All goods are packed in bundle with steel strips and shipped by break bulk vessel or container (depend on target market and different ports)

Delivery Detail: 45 days

Trade terms: FOB, CFR, CIF

MOQ: 25 tons per specification; we can negotiate the quantity if the specification is normal or we have stock of one specification.

Weight: The price invoicing on theoretical weight basis or actual weight basis depends on customer’s request.

Shipment: The shipment of bulk break or container is depends on customer’s request and the situation of the port of destination.

Documents given: Full set of original clean on board bill of lading; Original signed commercial invoice; Original packing list; Policy of insurance; Certificate of origin and what the target market needs.

Production Flow of Chinese Standard Round Bar

1. The common processes are preheated forging quenching, dual refinement solution process, cooling quenching and isothermal quenching. We use heat treatment for dual refinement solution process.

2. Material prepare (billet) — heat up — rough rolling — precision rolling — cooling — packing — storage and transportation

Characteristics of Chinese Standard Round Bar

1. The steel in which the main interstitial alloying constituent is carbon in the range of 0.12–2.0%.

2. As the carbon percentage content rises, steel has the ability to become harder and stronger through heat treating; however it becomes less ductile.

3. Quality should be in conformity with the specification of the manufacturer. Quantity and packing conditions should be in conformity with the term in the contract.

4. Regardless of the heat treatment, higher carbon content reduces weld ability. In carbon steels, the higher carbon content lowers the melting point.

- Q: What are the different types of steel round bar alloys for improved strength?

- There are several types of steel round bar alloys that provide improved strength, including carbon steel, alloy steel, stainless steel, and tool steel. Each of these alloys has different properties and compositions, making them suitable for various applications where enhanced strength is required.

- Q: What is the machinability of a steel round bar?

- The ease with which a steel round bar can be shaped, cut, and modified using machining processes determines its machinability. This property measures how easily the steel material can be worked on with tools like lathes, mills, drills, and cutting or shaping tools. Several factors influence the machinability of a steel round bar, including its chemical composition, microstructure, and any heat treatment it has undergone. Elements like sulfur, phosphorus, and lead can either enhance or hinder machinability, while alloying elements like chromium, molybdenum, and nickel can also have an impact. Steel round bars with high machinability are characterized by their ability to be easily cut, drilled, and shaped with minimal tool wear and power consumption. They also produce smooth, precise finishes with minimal surface defects. On the other hand, low machinability steel round bars are more challenging to work with and may require more power, specialized tools, and slower cutting speeds. Considering the machinability of a steel round bar is important when selecting materials for machining applications. Factors like desired cutting speed, tool life, surface finish, and overall machining efficiency should be taken into account. The specific machining operations, such as turning, milling, or drilling, will also influence the choice of steel round bar with suitable machinability. In conclusion, the machinability of a steel round bar is a crucial factor in determining its suitability for various machining processes. Understanding the machinability characteristics of different steel grades can help in selecting the most appropriate material for specific machining applications, ensuring efficient and effective machining operations.

- Q: What are steel round bars?

- Steel round bars are long, cylindrical metal bars that are made from steel. They are commonly used in various industries such as construction, manufacturing, and engineering. These bars are known for their strength, durability, and versatility. Steel round bars are typically produced through a hot rolling process, where a solid steel billet is heated and passed through a series of rollers to achieve the desired shape and size. They come in a range of sizes and grades, with different properties depending on the specific application. These bars are often used as structural components in buildings, as shafts in machinery, as support bars in concrete structures, and as raw material for the production of other steel products. Due to their high tensile strength and resistance to corrosion, steel round bars are widely preferred in the construction and manufacturing sectors.

- Q: What are the different standards for steel round bars?

- There are several different standards for steel round bars, including ASTM A36, ASTM A105, ASTM A276, ASTM A479, and ASTM A572. These standards outline the specific requirements for the chemical composition, mechanical properties, and dimensions of steel round bars for various applications.

- Q: Can steel round bars be used for making musical instruments?

- Yes, steel round bars can be used for making musical instruments. Steel is a versatile material with excellent strength and durability properties, making it suitable for various applications including musical instruments. Steel round bars can be used to create various components of musical instruments such as strings, rods, or even the main body of certain instruments. The specific type and grade of steel used will depend on the instrument and the desired sound quality. For example, some percussion instruments like xylophones or vibraphones use steel bars to produce different pitches and tones. Additionally, steel round bars can be used to create parts for wind instruments like saxophones or trumpets. However, it is worth noting that the choice of material for musical instruments is often a complex process that involves considering factors like resonance, tonal quality, and playability. Therefore, while steel round bars can be used, other materials like brass, wood, or even synthetic materials might be preferred for certain instruments to achieve the desired sound characteristics.

- Q: Can steel round bars be used for making propeller shafts?

- Yes, steel round bars can be used for making propeller shafts. Steel is a commonly used material for propeller shafts due to its strength, durability, and resistance to corrosion. Round bars, in particular, are often chosen for their shape, which provides optimal strength and load-bearing capabilities. The selection of steel grade and specific properties will depend on the requirements of the propeller shaft, such as the desired length, diameter, and torque capacity. Additionally, other factors like cost, weight, and manufacturability may also influence the choice of steel round bars for propeller shafts.

- Q: What are the advantages of using case-hardening steel round bars?

- Case-hardening steel round bars offer several benefits for various applications. To begin with, these round bars possess a toughened outer layer, known as the "case," while maintaining a softer and more malleable core. This unique combination allows for exceptional surface wear resistance, making them highly suitable for situations where the material encounters abrasive or erosive forces. Furthermore, the hardened outer layer enhances the overall strength and durability of the round bars, thereby extending their lifespan. Another advantage of case-hardening steel round bars lies in their remarkable ability to withstand heavy impact loads. The hardened outer layer acts as a protective barrier, effectively absorbing and dispersing the energy from impacts, thus preventing any deformation or breakage. This makes them particularly well-suited for applications involving substantial loads or impacts, such as in the fields of machinery or construction equipment. Moreover, case-hardening steel round bars provide enhanced resistance against fatigue. The hardened surface layer aids in distributing stresses evenly, reducing the likelihood of cracks or fractures developing during cyclic loading conditions. Consequently, they prove to be an excellent choice for applications that demand long-term durability and the ability to withstand repeated stress, such as in automotive components or gears. Additionally, these round bars demonstrate excellent machinability. The soft and malleable core allows for easy cutting, drilling, and shaping, while the hardened surface ensures the necessary wear resistance. This aspect makes them both cost-effective and efficient to work with, enabling them to be effortlessly molded into various shapes and sizes to meet specific design requirements. In conclusion, the utilization of case-hardening steel round bars offers a plethora of advantages, including outstanding wear resistance, high impact load resistance, improved fatigue resistance, and excellent machinability. These characteristics render them a versatile and dependable choice for a wide array of applications across industries such as automotive, construction, and manufacturing.

- Q: Three - grade thread Phi 10 steel can replace a grade Phi 12 round bar? Which elder knows, trouble pointing.

- The general situation is not possible, but sometimes as stirrup time, and has little effect on the structure, if 12 reinforced with missing a few, but not on the main force position is possible, sometimes supervision is not allowed.

- Q: Can steel round bars be used in automotive applications?

- Yes, steel round bars can be commonly used in automotive applications due to their strength, durability, and versatility. They are often used in various components such as axles, crankshafts, suspension parts, and steering columns, among others, to provide structural support and ensure the safe and efficient functioning of vehicles.

- Q: What is the difference between a centerless ground and a hot rolled steel round bar?

- A centerless ground steel round bar and a hot rolled steel round bar are two different types of steel bars with distinct characteristics. Firstly, the manufacturing process for each type differs. A centerless ground steel round bar is produced by passing the steel bar through a centerless grinder, which removes any surface imperfections and creates a precise and smooth finish. This process ensures the bar has tight tolerances and consistent diameter throughout its length. On the other hand, a hot rolled steel round bar is created by heating the steel billet at extremely high temperatures and then rolling it through a series of mills to achieve the desired shape and size. This process results in a rougher surface finish compared to centerless ground steel bars. In terms of physical properties, centerless ground steel bars typically have a higher level of dimensional accuracy and straightness due to the precision grinding process. This makes them suitable for applications where tight tolerances and precise measurements are required, such as in the manufacturing of machinery parts or precision tools. Hot rolled steel round bars, on the other hand, are known for their strength and durability. The heating and rolling process imparts desirable mechanical properties to the steel, such as increased hardness and toughness. These bars are commonly used in general construction, structural applications, and fabrication projects where strength and reliability are crucial. In summary, the main difference between a centerless ground and a hot rolled steel round bar lies in their manufacturing processes, surface finish, and intended applications. While centerless ground bars offer superior dimensional accuracy and smoothness, hot rolled bars are valued for their strength and resilience. The choice between the two depends on the specific requirements of the application at hand.

Send your message to us

Hot Rolled Steel Round Bar 6mm-150mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords