Carbon Steel Bar 1035 S35C C35

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Carbon Steel Bar 1035 S35C C35

Product Description

1, Diameter: 8mm-250mm rounds

5mm-9mm rods

2, Length: 2m, 3m, 5.8m, 6m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black, Polished, Galvanized

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

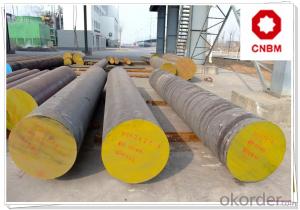

Products Show

Product Overviews

Description | Carbon Steel Rod/Carbon Steel Bar,carbon steel rod,carbon steel shaft,mild steel bar, Mild steel shaft,ms bar | |

Material | ASTM | 1005, 1006, 1008, 1010, 1015, 1020, 1025, 1030, 1035, 1040, 1045, 1050, 1055, 1060, 1065, 1070, 1080, 1084, 1016, 1022 |

DIN | Ck10, Ck15, Ck22, Ck25, Ck30, Ck35, Ck40,Ck45, Ck50, 30Mn4, 40Mn4 | |

BS | 040A04, 095M15, 045M10, 080A40, 045M10, 080M50 | |

JIS | S09CK, S9CK, S10C, S15C, S20C, S25C, S30C, S35C, S40C, S45C, S50C, S55C, S58C, SB45, S30C, S40C, S45C, S53C | |

Standard | GB/T799, ASTM A29, A108, A321, A575, BS970, DIN1652, JIS G4051 | |

| Section shape | Round, square, hexagonal, flat, angle | |

| Surface | Black painted, galvanized | |

Specifications | Round bar | Diameter: 4mm~1200mm |

Angle bar | Size: 3mm*20mm*20mm~12mm*800mm*800mm | |

Square bar | Size: 4mm*4mm~100mm*100mm | |

Flat bar | Thickness: 2mm~100mm | |

Width: 10mm~500mm | ||

| Hexagonal | Size: 4mm~800mm | |

Length | 2m, 4m, 5.8m, 6m, 11.8m, 12m or as required. | |

Work Shop

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: What is the difference between a forged and a ground steel round bar?

- A forged steel round bar and a ground steel round bar differ primarily in their manufacturing processes and resulting characteristics. A forged steel round bar is created by heating the steel to a high temperature and then shaping it using mechanical pressure, usually through a hammer or press. This process aligns the steel's grain structure, making it stronger and more durable. Forged steel round bars are known for their excellent strength, impact resistance, and overall toughness. They are commonly used in applications that require high strength, such as heavy machinery, automotive parts, and construction equipment. On the other hand, a ground steel round bar is manufactured through a grinding process. After the steel is initially shaped, it undergoes precision grinding to achieve the desired dimensions and surface finish. This process removes any imperfections or irregularities on the surface, resulting in a smooth and polished appearance. Ground steel round bars are often used in applications that require precise dimensions, such as shafts, axles, and precision tools. In summary, the main difference between a forged and a ground steel round bar lies in their manufacturing processes and resulting properties. A forged steel round bar offers superior strength and toughness due to its grain structure alignment, making it suitable for heavy-duty applications. On the other hand, a ground steel round bar is known for its precise dimensions and polished surface finish, making it ideal for applications that require precision.

- Q: Are steel round bars available in custom sizes?

- Yes, steel round bars are available in custom sizes. Steel round bars can be manufactured to meet specific size requirements and specifications. Custom sizes can be requested based on the diameter, length, and overall dimensions of the round bar. Whether it is for a specific project or application, many steel manufacturers and suppliers offer the option to customize the size of round bars to suit individual needs.

- Q: What is the difference between a seamless and a precision ground steel round bar?

- A seamless steel round bar is manufactured without any seams or welds, resulting in a smooth and uniform surface throughout the entire length. On the other hand, a precision ground steel round bar is manufactured with precise dimensions and surface finish, typically achieved through grinding or machining processes. This ensures tighter tolerances and a more accurate diameter, making it suitable for applications requiring high precision and tight dimensional control.

- Q: Are steel round bars magnetic?

- Yes, steel round bars can be magnetic. The magnetic properties of steel depend on its composition and processing. Most commonly used steel alloys, such as carbon steel or stainless steel, contain iron as the main component. Iron is a ferromagnetic material, which means it can be magnetized. Therefore, steel round bars made from these alloys will exhibit magnetic properties. However, it is important to note that the strength of the magnetism can vary depending on the specific composition of the steel. Some stainless steel alloys, for example, have a lower magnetic permeability and may exhibit weaker magnetic properties compared to carbon steel.

- Q: How are steel round bars used in the manufacturing of machinery and equipment?

- Steel round bars are widely used in the manufacturing of machinery and equipment due to their inherent strength, durability, and versatility. These bars are typically made from carbon steel or alloy steel and come in various diameters and lengths. One common application of steel round bars is in the fabrication of shafts and axles. These components are crucial for transmitting rotational motion and torque in machinery. Steel round bars provide the necessary strength and stiffness to withstand the forces and stresses experienced during operation. They are often machined to precise tolerances and then heat-treated to enhance their mechanical properties, such as hardness and toughness. Another important use of steel round bars is in the production of gears and sprockets. These components are essential for transmitting power and motion between different parts of a machine. Steel round bars are machined to form teeth or cogs that mesh together, ensuring smooth and efficient operation. The high strength and wear resistance of steel enable gears and sprockets to withstand heavy loads and repetitive motion without deformation or failure. Steel round bars are also utilized in the manufacturing of various machine components such as bearings, couplings, and fasteners. Bearings, for example, rely on the strength and hardness of steel to support rotating or sliding shafts while minimizing friction and wear. Couplings, on the other hand, utilize steel round bars to connect different machine parts, transmitting power and motion efficiently. Steel round bars are also used as fasteners, providing a secure and reliable connection between different machine elements. In addition to these applications, steel round bars are often employed in the construction of machine frames and structures. Their high strength-to-weight ratio makes them ideal for providing structural support and stability. By using steel round bars, manufacturers can build robust and reliable machinery and equipment that can withstand heavy loads, vibrations, and other challenging operating conditions. Overall, steel round bars play a vital role in the manufacturing of machinery and equipment. Their exceptional strength, durability, and versatility make them a preferred choice for a wide range of applications. Whether it is for shafts, gears, bearings, or machine frames, steel round bars provide the necessary mechanical properties to ensure the reliable and efficient operation of machinery and equipment.

- Q: How do steel round bars compare to aluminum or steel tubing?

- Steel round bars, aluminum tubing, and steel tubing all have their own unique properties and applications, so it is important to understand the characteristics of each material before making a comparison. Steel round bars are solid cylindrical bars made of steel. They are known for their high strength and durability, making them suitable for heavy-duty applications. Steel round bars have excellent tensile strength and can withstand high levels of stress and pressure. They are often used in construction, manufacturing, and engineering projects where strength and structural integrity are crucial. Steel round bars are also highly resistant to corrosion, making them suitable for outdoor and marine applications. Aluminum tubing, on the other hand, is made from aluminum, which is a lightweight and corrosion-resistant material. Aluminum tubing is known for its excellent thermal conductivity and electrical conductivity. It is often used in applications where weight reduction is important, such as in the aerospace and automotive industries. Aluminum tubing is also commonly used in the construction of heat exchangers and in electrical wiring systems due to its conductivity properties. Steel tubing, similar to steel round bars, is made of steel but is hollow in shape. Steel tubing is known for its versatility and wide range of applications. It is available in various shapes and sizes, including round, square, and rectangular, allowing for different structural designs. Steel tubing is often used in construction, automotive manufacturing, and industrial applications. It offers high strength and rigidity, making it suitable for applications that require structural support or the ability to withstand heavy loads. In comparison, steel round bars offer superior strength and durability compared to aluminum and steel tubing. They are ideal for heavy-duty applications that require high levels of strength and structural integrity. However, steel round bars can be heavier and more expensive than aluminum tubing, which is often preferred for lightweight applications. Steel tubing, on the other hand, provides versatility in terms of shape and size, allowing for more design options. Ultimately, the choice between steel round bars, aluminum tubing, and steel tubing depends on the specific requirements of the application, including factors such as strength, weight, cost, and corrosion resistance. It is important to carefully evaluate these factors and consult with experts to determine the most suitable material for a particular project.

- Q: Are steel round bars suitable for automotive applications?

- Steel round bars are an ideal choice for automotive applications. Their exceptional strength, durability, and resistance to corrosion make them a popular choice in the manufacturing of various automotive components. These components include axles, crankshafts, drive shafts, steering components, suspension systems, and chassis construction. Steel round bars possess the necessary strength and rigidity to withstand the demanding conditions of automotive use, such as heavy loads, vibrations, and impact forces. Moreover, they offer versatility and adaptability to different automotive designs and requirements as they can be easily machined, welded, and forged. In summary, steel round bars are not only dependable but also cost-effective for automotive applications.

- Q: Can steel round bars be used for making bicycle frames or handlebars?

- Yes, steel round bars can be used for making bicycle frames or handlebars. Steel is a commonly used material in bicycle manufacturing due to its strength, durability, and affordability. Round bars made of steel provide excellent rigidity and stability, which are essential for ensuring the structural integrity of a bicycle frame or handlebars. Additionally, steel has a high tensile strength, allowing it to withstand the stresses and strains experienced during cycling. It is worth noting that different types of steel, such as chromoly steel, may be preferred for bicycle frames and handlebars as they offer specific advantages such as improved strength-to-weight ratio. However, in general, steel round bars are a suitable choice for constructing bicycle frames and handlebars.

- Q: What are the advantages of using heat-treatable steel round bars?

- Using heat-treatable steel round bars offers several advantages: 1. Strength Enhancement: Controlled heating and cooling processes can be applied to heat-treatable steel round bars, which enhance their strength and hardness. This renders them suitable for applications demanding high strength and durability. 2. Enhanced Resistance to Wear: Heat treatment enables the development of a hardened surface layer on the steel round bars, significantly improving their wear and abrasion resistance. As a result, they are ideal for use in industries such as manufacturing, construction, and automotive, where components experience heavy wear and tear. 3. Tailored Customization: Heat-treatable steel round bars possess the advantage of easy customization to meet specific requirements. By adjusting the heat treatment process, the bars' hardness, strength, and other mechanical properties can be tailored to suit different applications, ensuring optimal performance. 4. Convenient Machinability: Heat-treatable steel round bars generally exhibit good machinability, allowing for easy cutting, drilling, or shaping into various forms without compromising their structural integrity. This convenience reduces production time and costs. 5. Versatility: Heat-treatable steel round bars find versatile applications across a wide range of industries, including construction, manufacturing, oil and gas, automotive, and aerospace. They are commonly utilized in the production of shafts, gears, bolts, axles, and other critical components. 6. Long-term Cost-effectiveness: Although heat-treatable steel round bars may initially have a higher cost compared to non-heat-treatable or lower-grade steels, their durability and enhanced properties make them cost-effective in the long run. The improved strength and wear resistance contribute to a longer service life, reducing the need for frequent replacements and maintenance. In conclusion, the utilization of heat-treatable steel round bars offers a multitude of benefits, including increased strength, improved wear resistance, customized properties, easy machinability, versatility, and long-term cost-effectiveness. These advantages position them as the preferred choice for demanding applications requiring high-performance materials.

- Q: How do steel round bars compare to concrete round bars?

- Steel round bars and concrete round bars have several key differences. Firstly, steel round bars are made of a strong and durable material, whereas concrete round bars are made of a composite material consisting of cement, aggregates, and water. This difference in materials gives steel round bars a higher tensile strength and resistance to bending and deformation compared to concrete round bars, which are more prone to cracking and breaking under stress. Secondly, steel round bars offer greater flexibility in terms of design and customization. They can be easily shaped, bent, and cut to specific lengths and dimensions, making them highly versatile for various applications. On the other hand, concrete round bars are usually available in standard sizes and shapes, limiting their design possibilities. Another important aspect to consider is the weight. Steel round bars are generally lighter in weight compared to concrete round bars, making them easier to handle and transport. This weight advantage also translates into reduced structural loads, allowing for more efficient and cost-effective construction. In terms of corrosion resistance, steel round bars require additional protective measures such as coatings or galvanization to prevent rust and corrosion, especially in humid or marine environments. Concrete round bars, on the other hand, are naturally resistant to corrosion. This can be a significant factor when considering the long-term durability and maintenance requirements of a structure. Lastly, cost is an important factor to consider. While steel round bars may have a higher initial material cost compared to concrete round bars, their superior strength and durability can lead to long-term cost savings. Concrete round bars may require more frequent maintenance and repairs, which can add up over time. In conclusion, steel round bars offer superior strength, flexibility, and durability compared to concrete round bars. However, the choice between the two depends on the specific requirements of the project, including factors such as design flexibility, weight considerations, corrosion resistance, and cost.

Send your message to us

Carbon Steel Bar 1035 S35C C35

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords