LOW CARBON FERRO CHROME 60% FOR STEEL MAKING

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Ferro Chrome

Chrome is always used to improve the antioxidation and corrosion resistance of steel to make the surface of steel after it is oxidized to form strong adhension oxide film. Then it stops being oxidized or decelerates being oxidized.Micro-Carbon ferro chorme is applied to making stainless, acid-resistant steel and heat resistant steel.

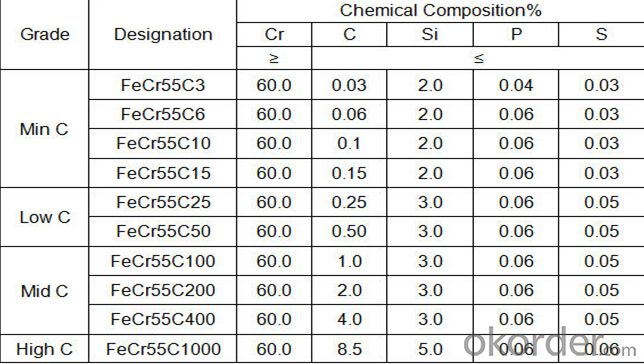

Specifications

Low Carbon Ferro Chrome

1. Original manufacturer

2. The stability of the shipments

3. Free samples

4. Relatively lower cost

Products information

1. It can be used to produce FerroChrome and Chrome metal in metallurgy industrial.

2. As a kind of steel addition,it is used to produce various special steels with high strength,corrosion resistance,anti-friction,thermostability and anti-oxydic.such as stainless steel,acid-resistant steel,heat-resistant steel,spring steel,tool steel and so on.

3. Chromite is used to produce Chrome brick,,Chrome-magnesium brick and other special refractories in fireproofing.

Packaging & Delivery

Packaging Detail: | 1MT/BAG |

Delivery Detail: | 15-30days |

- Q: How are hard alloy fittings machined and polished?

- Cutting tools or ceramic cutting tools for cubic boron nitride material, cobalt alloy cutting tools, etc.,Diamond grinding materials for polishing.

- Q: What are the differences between the two grades of carbide, YT15 and YT5?

- YT5 is often used for roughing or machining, impact cutting, and YT15 is usually semi finishing and finishing.

- Q: What are the grinding carbide wheels?

- Diamond grinding wheel, carborundum wheel. Only welded blades use carborundum wheels, and generally fine grinding blades use diamond grinding wheels.

- Q: Can CBN wheels grind cemented carbide? Why?

- Diamond grinding wheels are commonly used for grinding carbide. Because diamond is much harder than CBN, only CBN grinding wheel is selected for grinding iron family material. So we should choose diamond grinding wheel.

- Q: The use of cemented carbides YG and YT

- First, the more common processing carbide used in three categories,:1, YG--- tungsten cobalt alloy products, to YG6, generally suitable for processing iron, non-ferrous metals and their alloys and non-metallic materials continuous cutting of rough cars, intermittent cutting of the semi fine cars and fine cars.2, YT--- tungsten cobalt titanium alloy products, for YT5, for carbon steel and alloy steel rough section, intermittent cutting in the rough car, rough plane, half fine plane, non continuous surface roughing milling and drilling.3, YW---- tungsten, cobalt, titanium, tantalum alloy products.

- Q: Is there a material that is more wear-resistant than cemented carbide and has a relatively low cost?

- If it is numerical control tool, it is more wearable than cemented carbide: ceramic, CBN, diamondAmong them, the lowest price of ceramics, diamond prices are highest

- Q: Use of waste cemented carbide

- Two, crushing methodFor hard alloy containing drilling is not high, because the hardness is relatively low, can use manual or mechanical means broken to a certain fineness in wet grinding mill for a period of time, to reach a certain size for reproduction of hard alloy. This force is a method has the advantages of simple process, short process, low energy consumption, no pollution to the environment, but often in the manual crushing hard alloy, metallic materials due to debris into the tools have broken material pollution, in addition, due to the hard alloy drill containing high amount of easily broken, mechanical crushing method is very limited; cemented carbide complex material by this method is also very difficult to ensure the quality of recycled products. Process method: artificial crushing is broken, crushed into powder 200 mesh or using bulk of hard alloy ball mill for crushing strikes the ball, then add in the bjm alcohol in wet grinding, and then enter the remanufacturing process of hard alloy.Some companies use cooling method: first crushing waste hard alloy in a muffle furnace heated to 80 above this immediately into the water quench, resulting in hard alloy cracking, and then enter the mechanical crushing process. This force is a method in the last century in 90s in Hebei Province Qinghe to gain popularity, there were dozens of county size ranging from recycling plant using the recycled and processed hard alloy, hard alloy processed over a thousand tons of annual production, the total output value of 300 million yuan, becoming one of the local pillar industry. At present, there is still a certain space for development of the crushing method, and the crushing method still needs to be improved by adopting more advanced and clean crushing equipment or by means of the force method which does not destroy the microstructure of cemented carbide with high efficiency.

- Q: Classification of Cemented Carbides

- Upstairs is said that China's classification, ISO is divided into 6 categories: P, M, K, N, S, H., modern processing materials, 90% ~ 95% can be P class and K class carbide processing, and the rest of the material can be M class processing. You can see the ISO 513-2004 standard

- Q: One kind of steel is called T10, and another is carbon steel. What kind of hardness and strength do they have?

- T10 is a kind of carbon steel, carbon containing 1% carbon steel, excluding alloy elements, alloy steel is alloy element steel. The strength of carbon steel and alloy steel which has high hardness, not only carbon and alloy content, to look at the condition of heat treatment, even if the same carbon content of carbon steel and alloy steel under different heat treatment conditions, may be carbon steel high hardness alloy steel with high hardness can also be. Still do not understand this is not nonsense, domestic high quality steel, not only domestic technology is not in place, the user is not willing to pay a high price to buy high quality steel. Always want to spend less money to buy things, it is not possible.

- Q: Carbide and carbon steel

- Hard alloy knife, cutting knife, carbon steel is the food, so simple.

Send your message to us

LOW CARBON FERRO CHROME 60% FOR STEEL MAKING

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords