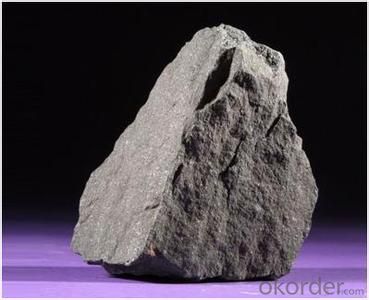

Ferro Silicon Alloy75% Inspection: CIQ SGS QA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.SGS/CIQ/ISO

2.Factory supply directly

3.Focus on the ferroalloy industry for more than ten years

4.Free samples

The introduction of the ferro silicon 75%

The introduction of the ferro silicon

Ferrosilicon has been widely applied.in the steel industry, foundry industry and other industrial production.

Ferrosilicon is indispensable deoxidizer in the steel industry., ferrosilicon is used for precipitation deoxidation and diffusion deoxidation in Ju steel. Brick iron also as an alloying agent used in steelmaking. Adding a certain amount silicon to the steel can significantly improve the strength, hardness,elasticity and permeability of steel, reduce the hysteresis loss of transformer steel.

High ferrosilicon or silicon alloys is used for the production of low-carbon reductant in ferroalloy industry. Adding ferrosilicon to cast iron can be inoculant for ductile iron, and can prevent the formation of carbides, and promote the precipitation of graphite and the nodulizing, so as to improve performance of cast iron.

In addition, ferrosilicon powder can be used as a suspended phase in the mineral processing industry,and coatings for welding electrodes in the electrode manufacturing

The application of the ferro silicon 75%

(1) in the steel industry used as deoxidizer and alloying agents.

(2) in the iron industry used as a nucleating agent and spheroidizing agent. Cast iron is a kind of important modern industrial metal materials, it is much cheaper than steel, easy to melt refining, excellent casting performance and seismic capacity is far better than steel. Especially the nodular cast iron, its mechanical performance at or near the steel mechanical property. Add a certain amount of silicon in cast iron can prevent iron in formation and precipitation of carbides, and promote the graphite spheroidizing, therefore in the nodular iron production, ferrosilicon inoculants is a kind of important separation graphite (help) and spheroidizing agent.

(3) used as a reductant in ferroalloy production. Not only chemical affinity between silicon and oxygen is very big, but also high silicon silicon carbon content is very low. So high silicon ferrosilicon (or siliceous alloy) is a low-carbon ferroalloy ferroalloy industry production more commonly used a reducing agent.

- Q: MIG and TIG welding of cobalt base carbide and medium low carbon steel, respectively, using copper wire and stainless steel wire. What kind of corrosive liquid should be used in the welding seam to be metallographic?MIG+ copper welding wire, MIG+ stainless steel wire, TIG+ stainless steel wire

- Cobalt based alloy is a cemented carbide that is capable of various types of wear and corrosion as well as high temperature oxidation. Commonly known as the cobalt chromium tungsten (molybdenum) alloy or Si Taili (Stellite) alloy (Si Taili alloy invented by the American Elwood Hayness in 1907).

- Q: What kinds of carbide cutting tools are used in the 16 and 20 manganese grinding of the lathe?

- Commonly used in 200*25*32 or 250*25*32 green carbide grinding wheel, hardness K or L, particle size 60.Cemented carbide: an alloy material made from powder metallurgy by hard metals and bonded metals of refractory metals. Hard alloy is widely used as a tool material, such as turning, milling, planing, drilling, boring, used for cutting cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone and steel, can also be used for cutting steel, stainless steel, high manganese steel, tool steel and other hard processing materials. Now, the cutting speed of new carbide tools is several times that of carbon steel. Hard alloy with high hardness, strength and toughness, good wear resistance, heat resistance, corrosion resistance and a series of excellent performance, especially high hardness and wear resistance of it, even at a temperature of 500 DEG C also remained unchanged, at 1000 degrees C still have high hardness.

- Q: What are the cemented carbides?

- General tungsten cobalt alloy is mainly applicable to: carbide cutting tools, molds and mineral products. Carbide cutting toolTungsten, titanium and cobalt carbideThe main components are tungsten carbide, titanium carbide (TiC) and cobalt. The grade by "YT" ("hard ti" Pinyin prefix) and the average content of titanium carbide.

- Q: What are the three types of commonly used cemented carbides?

- As the mass fraction of cobalt increases, the hardness and wear resistance decrease, and the flexural strength and toughness increase.M class (equivalent to our YW class), cemented carbide is based on WC, TiC, Co, and then added TaC (or NbC). After the addition of TaC (or NbC), the comprehensive properties of cemented carbide were improved. This kind of cemented carbide can process both cast iron and non-ferrous metals, and also can process steel materials. It can also process difficult materials such as high temperature alloy and stainless steel. Commonly used brands are YW1 and YW2.

- Q: What brand of carbide is used in woodworking tools?

- The quality alloy YG6X/YG6A is suitable for the processing of chilled cast iron, alloy cast iron, heat-resisting steel and alloy steel. It is also suitable for the fine machining of precision cast iron and the manufacture of wear-resistant parts. Hard alloy YG8N: is suitable for fine cast iron, ductile iron, white iron and non-ferrous metal finishing.

- Q: How to distinguish cemented carbide grades?

- Carbide how to distinguish between help you answer the following, I hope to help youCommonly used carbide WC as the main component, according to whether to join other carbide is divided into the following 3 categories:(1) tungsten cobalt (WC+Co) cemented carbide (YG), as long as pig iron is processedIt consists of WC and Co which has higher flexural strength, toughness, good thermal conductivity, but heat resistance and poor wear resistance, mainly used for processing cast iron and nonferrous metals. YG hard alloy fine grain (such as YG3X, YG6X), in the same amount of cobalt, the hardness, wear resistance than YG3 YG6 high strength and toughness is poor, suitable for machining hard cast iron, austenitic stainless steel, heat-resistant alloy, hard bronze.(2) tungsten titanium cobalt hard alloy (WC+TiC+Co) (YT) "the main processing of wrought iron"Because of the hardness and melting point of TiC was higher than WC, so compared with YG, the hardness, wear resistance, hardness increases, bond high temperature, strong antioxidant capacity, and will generate TiO 2 at high temperature can reduce the adhesion. But poor thermal conductivity, low flexural strength, so it is suitable for processing steel etc. the toughness of materials.

- Q: What is the hardness of cemented carbide?

- Different grades, different hardness, usually (86 ~ 93HRA, equivalent to 69 ~ 81HRC);

- Q: Dalian enterprises now need 16.3 and 19.3 mm in diameter, the whole cold hard alloy bit, where can I find buyers? Leave a contact

- Xi'an Jie Electrical Machinery Co., Ltd. internal cooling alloy drill, factory direct sales

- Q: Carbide saw blades, plain and alternating teeth. What do you mean? That good?

- The 3. ladder flat tooth is a combination of trapezoidal teeth and peace teeth, and the grinding is more complicated. When sawing, the utility model can reduce the phenomenon of overlaying and cracking, and is suitable for sawing and cutting all kinds of single and double facing artificial boards and fireproof boards. Aluminum saw blade, in order to prevent adhesion, but also more flat teeth with more teeth.4. ladder tooth often used for cutting saw blade trough, in artificial plate sawing double veneer, adjust the thickness of the bottom surface of the groove saw complete grooving, the main saw complete plate sawing, cutting edge to prevent the occurrence of collapse phenomenon.In summary, sawing wood, particleboard, MDF or tooth, can be sharp wood fiber cut, cut smooth; in order to keep the grooving bottom flat, with flat tooth or flat composite tooth; sawing plywood, fireproof board generally choose ladder flat teeth, is expected to open the computer the sawing sawing rate, diameter and thickness of the alloy blades are relatively large, about 350-450mm in diameter, 4.0-4.8mm in thickness, most of the ladder flat teeth, in order to reduce the edge collapse, saw.

- Q: What are the main causes of wear of high speed steel cutting tools and carbide cutting tools?

- (1) mechanical wear: the abrasion caused by the friction between the chip and the cutter front, the surface deformation of the workpiece and the sharp friction between the cutter face, called mechanical wear.When the cutting temperature is not too high, the mechanical abrasion caused by this friction is the main cause of tool wear.(2) thermal wear: when cutting, because of the severe plastic deformation and friction of metal, the cutting heat makes the blade hardness decrease, and the wear and tear caused by cutting performance is called thermal wear.It is recommended that the Santak wick tool be used to solve the wear problem.

Send your message to us

Ferro Silicon Alloy75% Inspection: CIQ SGS QA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords