LOW CARBON FERRO CHROME

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Ferro Chrome

Chrome is always used to improve the antioxidation and corrosion resistance of steel to make the surface of steel after it is oxidized to form strong adhension oxide film. Then it stops being oxidized or decelerates being oxidized.Micro-Carbon ferro chorme is applied to making stainless, acid-resistant steel and heat resistant steel.

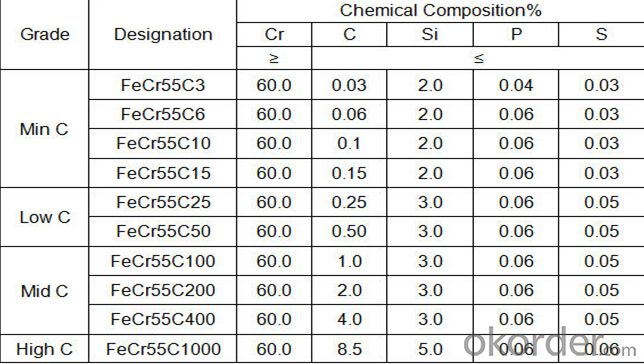

Specifications

Low Carbon Ferro Chrome

1. Original manufacturer

2. The stability of the shipments

3. Free samples

4. Relatively lower cost

Products information

1. It can be used to produce FerroChrome and Chrome metal in metallurgy industrial.

2. As a kind of steel addition,it is used to produce various special steels with high strength,corrosion resistance,anti-friction,thermostability and anti-oxydic.such as stainless steel,acid-resistant steel,heat-resistant steel,spring steel,tool steel and so on.

3. Chromite is used to produce Chrome brick,,Chrome-magnesium brick and other special refractories in fireproofing.

Packaging & Delivery

Packaging Detail: | 1MT/BAG |

Delivery Detail: | 15-30days |

- Q: I only know a few big, like Zhuzhou, Chun Bao, Xiamen tungsten diamond. Anything else? I'm looking for a tool cutter

- I heard that Zhuzhou is better, you say diamond coated knives? This is the tool of two different materials, diamond is not coated

- Q: Machining center 8 mm carbide cutter processing 45 steel, how to set the speed, feed, and moving speed?

- You should be a 8 mm tungsten steel milling cutter, the speed should be controlled below 2200 to 3000, because the speed and your cutting are related to the amount of advice:

- Q: What is hard alloy grinding?

- Diamond grinding wheel in grinding hard alloy and non-metallic materials, has a unique effect, but in the grinding of steel material, especially grinding special steel, the effect is not significant. It is composed of cubic boron nitride (CBN) grinding cubic boron nitride particles sticking to the ordinary wheel surface only a very thin layer, the abrasive wear the hardness, toughness and durability of corundum wheel is 100 times, the most suitable for processing high hardness, high viscosity, high strength, low thermal conductivity of grinding hard steel and high or super high speed grinding.

- Q: the blade is hard alloy, the processing material is QT600, the plane lower tool margin is 4mm, the speed and the knife

- This belongs to the category of ductile iron, more difficult to process, because the material is hard particles, it is recommended around S=1200 F=400

- Q: What is the hardness of YG8 cemented carbide?

- YG8 is a tungsten cobalt type material.Good wear resistanceDensity / (g/cm3): 14.5-14.9Hardness (HRA): 89Flexural strength (sigma bb/MPa): 1500Impact toughness K/ (J/cm2): 2.5

- Q: What are the fields of nano WC Cemented Carbides applied?

- (2) electronic industry. The development trend of electronic products is miniaturization, integration and precision. The integrated circuit board is made of epoxy resin, glass fiber or glass fiber reinforced plastic. This requires micro drill has high hardness and wear resistance; while the drill diameter is very small (generally 0.2 ~ 0.3mm, and 0.05mm), easy to break, also called bit has high strength and toughness, and need to correct drilling hole position accuracy, and the drill bit has high stiffness (elastic modulus). These conflicting requirements. The common hard alloy and fine grain carbide drills are difficult to meet these requirements, only the use of nano grain carbide grain size of less than 0.5 m. And as the dot printing needle, its diameter is only 0.2-0.35mm; multi frame processing integrated circuit lead by the progressive die, punch thickness less than 0.2mm, the error is only 0.002mm; in addition to the printed circuit board with wire cutting head disc cutter, and the precision of the small die, all require the use of Nanocrystalline WC cemented carbide in order to achieve its function to produce alloy.

- Q: What about cemented carbide produced in Zhuzhou? What brand is good?

- Diamond brand still has a certain position, the 1 floor said that the fine carbide sales company, I pass there every day, but also put Alibaba lights in there

- Q: What are the types and types of carbide inserts?

- There are too many blades, just a few examples of YG3 (used in cast iron, non-ferrous metals and alloys, precision cars or semi fine cars)YT14 (for carbon and alloy steel, semi fine and precision cars)YW1 (applicable to heat resistant steel, high Menggang, stainless steel processing, can also be used for general materials)

- Q: What does P stand for and what is 30? What are its advantages and disadvantages? What is suitable for processing?

- Cemented carbides are classified into 3 categories, and the ISO standards are defined as K, P, and m three. Each corresponds to the YG class, the YT class, and the YW class in our country. The material properties of P30 correspond roughly to the performance of our brand YT5. Suitable for carbon and alloy steels. But it is not suitable for machining titanium alloy or brittle material, because this kind of cemented carbide with high hardness, good wear resistance, but the strength is not enough, cutting the material easily.

- Q: Is it hard to make carbide cutting tools for aluminum alloy?

- High speed tool steel is essentially tool steel, but heat resistance is betterHard alloy is made of tungsten carbide, titanium carbide materials such as superhard materials. From the hardness and red hardness, high speed tool steel paima couldn't catch up. Although the name as "alloy" two words, it is actually a kind of metal ceramic.

Send your message to us

LOW CARBON FERRO CHROME

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords