Ferro Silicon Origin In Qinghai Province CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Usage

Ferro silicon is widely used in the steel making,iron casting ,low-carbon ferroalloy producing:

1 In the steel making field,Ferro silicon is used as deoxidizer and alloying agent to precipit and diffusedeoxidation.Adding a certain amount silicon of fe-si to the steel can obviously improve the strength ,hardness ,elasticity and permeability of steel.

2 In the iron casting,it is used as ball mile agent and alloying agent especially in the nodular iron casting, Adding ferrosilicon to cast iron ,it can prevent the formation of carbide and promote the precipitation of graphite and the nodulizing.then the mechanical capacity can be the same of steel's.

3 High-silicon ferrosilicon can be used for the production of the low-carbon reductant in ferro alloy industry.

4 In addition ,ferro silicon powder can be used as a suspended phase in the mineral processing industry and coatings for welding electrodes in the electrode manufactruing.

Application

Used as deoxidants and desulfurizing agents, and could purity the molten steel, etc. The size includes:0-3mm, 3-25mm,10-50mm, etc.

Packaging & Delivery

Packing Details: In 1 MT Jumbo Bags

Delivery Detai | Within 30 days after received the deposite |

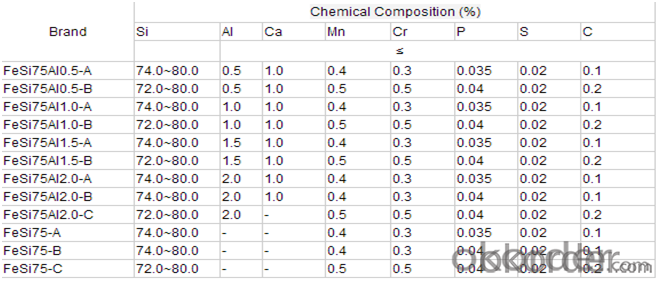

Specification

- Q: I only know a few big, like Zhuzhou, Chun Bao, Xiamen tungsten diamond. Anything else? I'm looking for a tool cutter

- There are a lot of ah, as you said, Zhuzhou Chun Bao, Xiamen tungsten, diamond, and Zigong hard alloy, Yun Li tool, these are made of hard materials, specifically to look at you is to do what tool, what materials processing, our factory is processing of steel, aluminum, plastic and so on. The benefit is to allow the tool, think the price is good, mainly to see you to say what material processing. It's purely personal. It doesn't involve advertising. Please accept it if you feel ok.

- Q: What does WC refer to in cemented carbides?

- Refers to: tungsten carbide powder, is the main raw material for the production of cemented carbide, chemical formula WC. Full name: tungsten carbide powder is black, six square crystal, has metallic luster, hardness is similar to diamond, it is good conductor of electricity and heat.

- Q: What is the specific gravity of cemented carbide?

- Similar to mercury. Tungsten cobalt carbide 14.4~15.3 density, tungsten, cobalt, titanium carbide 9.7~13.2 density, can float in the mercury is a steel knife, sink into the mercury is a cast iron knife

- Q: Machining center 8 mm carbide cutter processing 45 steel, how to set the speed, feed, and moving speed?

- You should be a 8 mm tungsten steel milling cutter, the speed should be controlled below 2200 to 3000, because the speed and your cutting are related to the amount of advice:

- Q: the blade is hard alloy, the processing material is QT600, the plane lower tool margin is 4mm, the speed and the knife

- This belongs to the category of ductile iron, more difficult to process, because the material is hard particles, it is recommended around S=1200 F=400

- Q: What cemented carbide does 2gr13 use?

- 2Cr13 martensitic stainless steel can be processed by hard alloy YW2, carbide YW2 suitable for heat-resistant steel, high manganese steel, stainless steel and advanced alloy steel and other special difficult to processing steel finishing, semi finishing.

- Q: What type of emery grinding machine is 3000/min for grinding carbide turning tools (e.g., YG8.YS8.YT15.YW1, etc.)?

- Diamond grinding wheel, green carborundum wheel can be used. Two, choose one, or choose the former good. Diamond grinding wheel has the advantages of less wear, long life, high productivity and good processing quality, that is, the price is a little more expensive.Grinding wheel: grinding wheel is also called consolidation grinding tool. It is a kind of consolidation grinding tool, which is bonded by the bond agent into a certain shape (most round, central through hole) and has a certain strength. It is generally made up of abrasives, binders and pores. These three parts are often called the three elements of the bonded abrasives. In accordance with the different classification of binders, there are common ceramic (bond) grinding wheel, resin (bond) grinding wheel, rubber (bond) grinding wheel. The grinding wheel is one of the largest amount of abrasives, widely used, when using high-speed rotation can be cylindrical, metal or nonmetal workpiece inner circle, plane and various surface of rough grinding, semi fine grinding and fine grinding and notching and cutting etc.. The characteristics of grinding wheel are mainly determined by abrasive, particle size, bond, hardness, microstructure, shape and size.

- Q: What are the fields of nano WC Cemented Carbides applied?

- (3) wood processing. As early as 50s, carbide tipped tools were used in the wood processing industry. Now, there sheet of all kinds of materials, the processing precision and the requirements of the appearance is greatly improved, the centrifugal force, when high speed cutting cutting force so that ordinary hard alloy is difficult to meet the requirements of the processing, and nanocrystalline WC cemented carbide has been useless.

- Q: The welding welding hard alloy cutter, should use what type of flame why

- With the fire on it. Put the knife and put some red hot and then put up with borax alloy outer flame burning red and then placed in a good point copper alloy and borax on the use of knife gap flow with upper and lower outer flame burnt gap can be

- Q: The difference between cemented carbide and tungsten.

- Cemented carbide is a kind of alloy material made by powder metallurgy process of hard metal and bonding metal of refractory metal.Hard alloy with high hardness, strength and toughness, good wear resistance, heat resistance, corrosion resistance and a series of excellent performance, especially high hardness and wear resistance of it, even at a temperature of 500 DEG C also remained unchanged, at 1000 degrees C still have high hardness.Hard alloy is widely used as a tool material, such as turning, milling, planing, drilling, boring, used for cutting cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone and steel, can also be used for cutting steel, stainless steel, high manganese steel, tool steel and other hard processing materials.

Send your message to us

Ferro Silicon Origin In Qinghai Province CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords