Low Carbon -Ferro-Manganese CO2 Chinese Cargo

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Low Carbon -Ferro-Manganese CO2 Chinese Cargo

Ferro manganese

1. Mainly used as alloy additives and deoxidizer in steelmaking.

2. Used as alloy agent ,widely applied to be widely applied to alloy steel, such as structural steel, tool steel, stainless and

heat-resistant steel and abrasion-resistant steel.

3. It also has the performance that it can desulfurize and decrease the harmfulness of sulfur. So when we make steel and cast iron, we always need certain account of manganese.

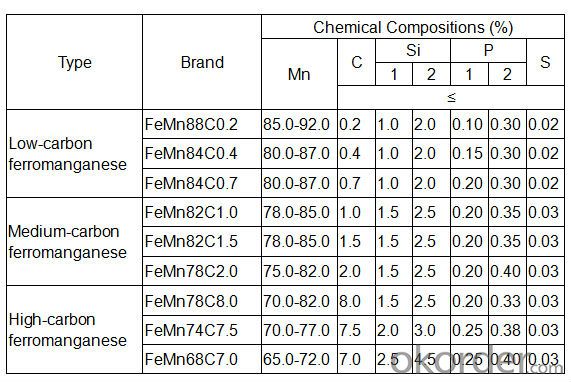

The specification and size:

Can be made as your demand.

Usage:

Metallurgy

PICTURES:

- Q: Are there any German products called K44 which are imported into cemented carbide materials? I am machining hole, K44 is better than domestic material K30?

- Germany never heard of K44, I know K40 is the international organization for standardization as the equivalent of the national standard YG-10H, the hardness of about 1300HV, used for processing softwood or hardwood and nonferrous metal; K30 is equivalent to the national standard YG-8, the hardness of about 1400HV, suitable for low hardness of grey cast iron, low tensile strength steel and compressed wood.Compared with the two, K40 has higher toughness, but its wear resistance is lower.

- Q: What kind of carbide alloy is used in stainless steel processing?

- Machine tool steel. Better cooling, liquid viscosity and sulfur chosen for good cooling performance, the pressure of the cooling liquid chlorine.

- Q: What materials are ZK20 cemented carbides processed?

- ZK20 belongs to the K hard alloy blades can car many materials, such as: wrought iron steel low alloy cast iron high alloy cast iron ductile cast iron Aluminum Alloy hard plastic

- Q: Hard alloy die mold grinding angle how slim

- The diamond electric grinding head can be polished, and the electric grinding head has a conical grinding head. Place the grinding head on a drill press or polish on an electric tool. Can the hard alloy die is caught in the lathe, grinding with diamond file.

- Q: What is the difference between the raw and recycled materials of cemented carbides? The more specific, the better

- Raw raw materials are raw materials, recycled materials have been used, and then recycled and re produced, raw materials than recycled materials used, and more pure materials.

- Q: What about cemented carbide produced in Zhuzhou? What brand is good?

- Is good at home, as for the brand well of course is diamond, refined into a brand is also good, there are fine into hard alloy sales company, previously entered a large red facade, product is very much, the Diamond Road No. 24-5, hope to help to you.

- Q: What is the hardness of the carbide thread?

- The hardness of cemented carbide tools is generally between 89~92.8, such as the hardness of YG8 is HRA89, the hardness of YT30 is 92.8, and the hardness of YT15 is 91.

- Q: I've seen a lot of classification, what tools, hardware, machinery, machinery, metallurgy, minerals, etc.,But I always don't know what the hard alloy belongs to. What can I do for you?

- The original should belong to the tool industry, because the use of hard alloy cutting tools, cutting tools, do some, such as measuring. Now the application of cemented carbide is becoming more and more widespread, and it should be more machining.

- Q: Customers ask whether cemented carbide can be used in the food industry! ~

- Used for processing food should not be possible, the composition of tungsten carbide.

- Q: What does P stand for and what is 30? What are its advantages and disadvantages? What is suitable for processing?

- 1.p stands for ferrous metals suitable for working long cuts.2.p30 is suitable for working steel, cast steel, long cut malleable iron. Suitable for general rough machining.

Send your message to us

Low Carbon -Ferro-Manganese CO2 Chinese Cargo

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords