low Carbon -Ferro-Manganese C0.4

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Ferro manganese

1. Mainly used as alloy additives and deoxidizer in steelmaking.

2. Used as alloy agent ,widely applied to be widely applied to alloy steel, such as structural steel, tool steel, stainless and

heat-resistant steel and abrasion-resistant steel.

3. It also has the performance that it can desulfurize and decrease the harmfulness of sulfur. So when we make steel and cast iron, we always need certain account of manganese.

The specification and size can be made as your demand.

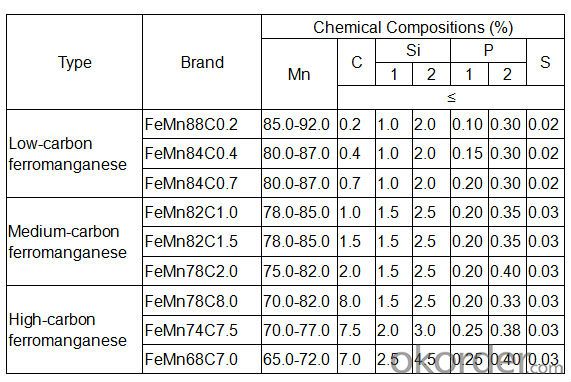

PICTURE

- Q: Y represents the metallurgical (Yejin) Department standard. W stands for universal (Wanneng) alloy

- Ha ha, I'm good at that!HC is the sign of the attractive magnetic force of the alloy, and HRA is the sign of hardness. COM is the cobalt magnetic mark of the alloy. D is the density of the alloy. The general quality certificate of the alloy product will have three indexes above

- Q: Why is carbide cutting tools less standard than high speed steel cutting tools?

- Because carbide cutting tools wear better than high speed steel cutting tools.

- Q: What are the parameters of the wear resistance of cemented carbides in addition to their hardness?

- Even the best knives in the world, if not1, reasonable processing parameters;2 、 proper installation and use;3 、 timely maintenanceAnd so on, it will turn into a scrap of iron in a short time.

- Q: What kinds of carbides are there? How should we choose in production?

- Basically divided into four major categories: YG, YW, YS, YT.YG is cast iron, nonferrous metal, base alloy steel.YW is made of stainless steel and base alloy steel.YS is the finishing of high strength steel, steel and cast steel.YT is the rough processing of steel and cast steel.

- Q: Classification of Cemented Carbides

- Upstairs is said that China's classification, ISO is divided into 6 categories: P, M, K, N, S, H., modern processing materials, 90% ~ 95% can be P class and K class carbide processing, and the rest of the material can be M class processing. You can see the ISO 513-2004 standard

- Q: What kinds of carbide knives do you have? Write out its main functions and uses.

- (3) tungsten tantalum cobalt (WC+TaC+Co) cemented carbide (YA);The addition of TaC (NbC) on the basis of YG cemented carbide improves the hardness and strength, thermal shock resistance and wear resistance at room temperature, high temperature, and can be used to process Cast Iron and stainless steel.(4) tungsten, titanium, tantalum, cobalt (WC+TiC+TaC+Co) and hard alloy (YW), such as W1, W2 and so on.On the basis of YT cemented carbide, TaC (NbC) is added to improve the flexural strength, impact toughness, high temperature hardness, oxygen resistance and wear resistance. Both can process steel, but also the processing of cast iron and non-ferrous metals. Therefore, it is often called universal cemented carbide (also known as universal cemented carbide). At present, mainly used for processing heat-resistant steel, high manganese steel, stainless steel and other difficult materials.

- Q: Carbide saw blades, plain and alternating teeth. What do you mean? That good?

- .1., about the most widely used teeth, cutting speed, grinding relatively simple. Suitable for cutting and crosscut various soft and hard wood materials and MDF, plywood, particleboard etc.. Equipped with anti elastic protection around the tooth is tooth plate for dovetail, longitudinal cutting of various degree; with negative rake angle of tooth saw blade sharp, serrated cutting because of good quality, usually used for veneer cutting.2. flat tooth saw is rough, cutting speed is slow, grinding is the most simple. Mainly used for sawing ordinary wood, the cost is lower, more used for smaller diameter aluminum saw blade, in order to maintain cutting to reduce adhesion, or used for grooving saw blade, to keep the groove bottom leveling.

- Q: We'll drill on the stainless steel column. Which bit is better?

- If it's cylindrical carbide, it's better to be on the drill bit or as a guide

- Q: 5 meters long hard alloy bars, where are they sold?

- Almost impossible to sell, you can choose to use media, multi section welding, bonding completed.AskMultistage welding? What welding is it?Chasing the answerUsing a steel as the matrix, the copper inserts are used to complete the desired specifications.

- Q: I want to process more hard stainless steel, with YC45 this type of carbide knife can do? Where can I buy authentic, know the friend told me, thank you

- Not suitable. YC45 is used for rough machining of general steel.If you have a low nickel content in your stainless steel, it is more suitable to use YD101 after hardening. If the nickel is high and the material is highly ductile, use the YBM series.Domestic hard alloy Zhuzhou diamond is better, you find a formal agent in Zhuzhou near you to buy.

Send your message to us

low Carbon -Ferro-Manganese C0.4

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords