Light Gauge Aluminum Sheets for Cookware - Continuous Casting Aluminum Coils Oklahoma

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

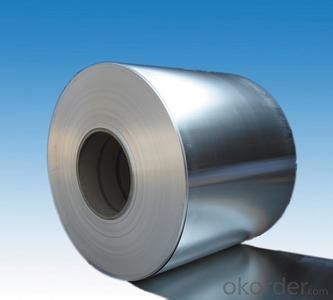

1.Structure of Continuous Casting Aluminium Coils for Cookware

Continuous Casting Aluminium Coils for Cookware is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Continuous Casting Aluminium Coils for Cookware

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2MM-3MM | 1000MM-1800MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: How do aluminum sheets perform in terms of flexural strength?

- Aluminum sheets are widely recognized for their remarkable flexural strength properties. Their inherent structural integrity and high strength-to-weight ratio allow them to endure bending forces without experiencing significant deformation or failure. The flexural strength of aluminum sheets is subject to variation based on factors like the chosen alloy, temper, and sheet thickness. Nevertheless, aluminum sheets are generally acknowledged for their impressive resistance to bending and ability to withstand applied loads without buckling or breaking. Consequently, aluminum sheets find extensive application in industries such as construction, automotive, aerospace, and marine, where components must endure flexural stresses. Furthermore, the flexural strength of aluminum sheets can be further enhanced through the utilization of diverse fabrication techniques and alloying elements, thereby optimizing their suitability for specific applications.

- Q: I need help with this question for a report i'm doing, it's about recycling aluminium, please could you give me some reasons why to recycle aluminium and eg.saves energy, and how it does eg. saves energy by...Thanks a lot this will help me loads.P.S this is just a report for my science project.

- Aluminum has to be extracted from the earth which is costly and takes a lot of energy. Then the aluminum needs to be smelted out of the rock that it is in, again this takes a lot of energy and creates toxins. Aluminum like all metals are finite, we conserve resources and the land where they will need to be extracted by recycling it.

- Q: I've had a Champion bass boat forever, but today I bought an aluminum G3 boat that was so cheap I couldn't pass it up. The G3 is aluminum. What are the pros and cons?

- This Site Might Help You. RE: What are the advantages/disadvantages of aluminum vs fiberglass bass boat? I've had a Champion bass boat forever, but today I bought an aluminum G3 boat that was so cheap I couldn't pass it up. The G3 is aluminum. What are the pros and cons?

- Q: How do you prevent oil or grease stains on aluminum sheets?

- To avoid oil or grease stains on aluminum sheets, there are several steps you can take: 1. Make it a habit to regularly clean the aluminum sheets. This will help eliminate any existing stains and prevent them from building up. Use a mild detergent or a mixture of water and vinegar to clean the sheets. Avoid using harsh cleaners or abrasive pads as they may harm the surface. 2. Apply a protective coating to create a barrier between the aluminum surface and oil or grease. Clear lacquer or anodizing are examples of coating options available. These coatings create a smooth and impermeable surface, making it difficult for oil or grease to penetrate and stain the aluminum sheets. 3. Use a barrier material if you frequently work with oil or grease near aluminum sheets. Consider using a silicone mat or placing parchment paper or aluminum foil between the aluminum sheet and the source of oil or grease to prevent direct contact. 4. Proper storage is crucial for preventing oil or grease stains on aluminum sheets. Store them in a clean and dry environment, away from potential sources of contamination. Keep the sheets covered or wrapped in a protective material to prevent dust, dirt, or oil from settling on the surface. 5. Handle aluminum sheets with clean hands. Ensure your hands are free of oil or grease before touching the sheets. Even small amounts of oil or grease on your hands can transfer onto the sheets and cause stains. If necessary, wear clean gloves or use clean tools when working with aluminum sheets to minimize the risk of stains. By implementing these preventive measures, you can significantly reduce the likelihood of oil or grease stains on your aluminum sheets, keeping them clean and in excellent condition.

- Q: Are aluminum sheets suitable for food storage containers?

- Yes, aluminum sheets are suitable for food storage containers. Aluminum is a lightweight and versatile metal that is commonly used for food packaging and storage. It is non-toxic, non-reactive, and does not impart any taste or odor to the food stored in it. Aluminum containers are also resistant to corrosion, which helps to keep the food fresh and prevent any contamination. Additionally, aluminum is a good conductor of heat, allowing for efficient cooling or heating of the food. It is also recyclable, making it an eco-friendly choice for food storage containers. Overall, aluminum sheets are a popular and reliable option for storing food safely and effectively.

- Q: This question asks for methods to prevent rusting on aluminum sheets while they are being stored or transported.

- <p>To prevent rusting on aluminum sheets during storage and transportation, follow these steps: Store the sheets in a dry, cool environment away from moisture and humidity. Use protective coverings such as plastic wraps or sheets to shield them from dust and water. Avoid stacking them directly on the ground; use pallets or racks to keep them elevated. Regularly inspect the sheets for any signs of moisture or damage. If possible, apply a protective coating or sealant specifically designed for aluminum to create a barrier against corrosion. Proper handling and packaging can also reduce the risk of scratches or dents that could lead to rust.</p>

- Q: Does it make any difference shiny side up, shiny side down when it comes to cooking with aluminum foil?

- With the shinny side up the heat is reflected away from the contents. With the Dull side out the heat is greater inside the pouch.

- Q: Are aluminum sheets resistant to chemicals?

- Yes, aluminum sheets are generally resistant to a wide range of chemicals.

- Q: Can aluminum sheet be used for cookware?

- Yes, aluminum sheet can be used for cookware. Aluminum is a popular choice for cookware due to its excellent heat conductivity and lightweight properties. However, it is usually combined with other materials, such as stainless steel or non-stick coatings, to enhance its durability and prevent any potential reactions with certain foods.

- Q: Can aluminum sheets be used for electronic devices?

- Yes, aluminum sheets can be used for electronic devices. Aluminum is widely used in the electronics industry due to its excellent conductivity, lightweight nature, and thermal management properties. It is commonly used as a base material for printed circuit boards (PCBs), heat sinks, enclosures, and other components in electronic devices.

Send your message to us

Light Gauge Aluminum Sheets for Cookware - Continuous Casting Aluminum Coils Oklahoma

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords