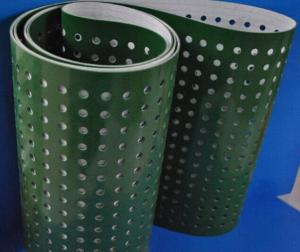

Light Duty PVC Conveyor Belt with Punching Hole

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Light Duty PVC Conveyor Belt with Punching Hole

Descriptions of PVC Conveyor Belt

PVC Conveyor Belt with Punching Hole

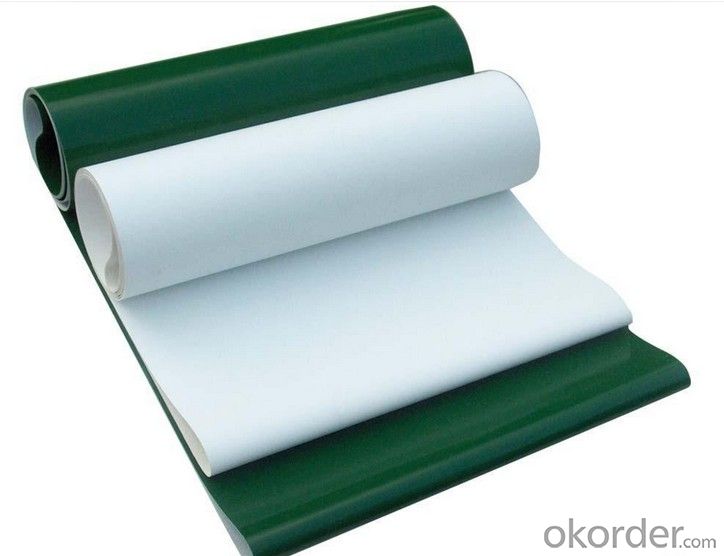

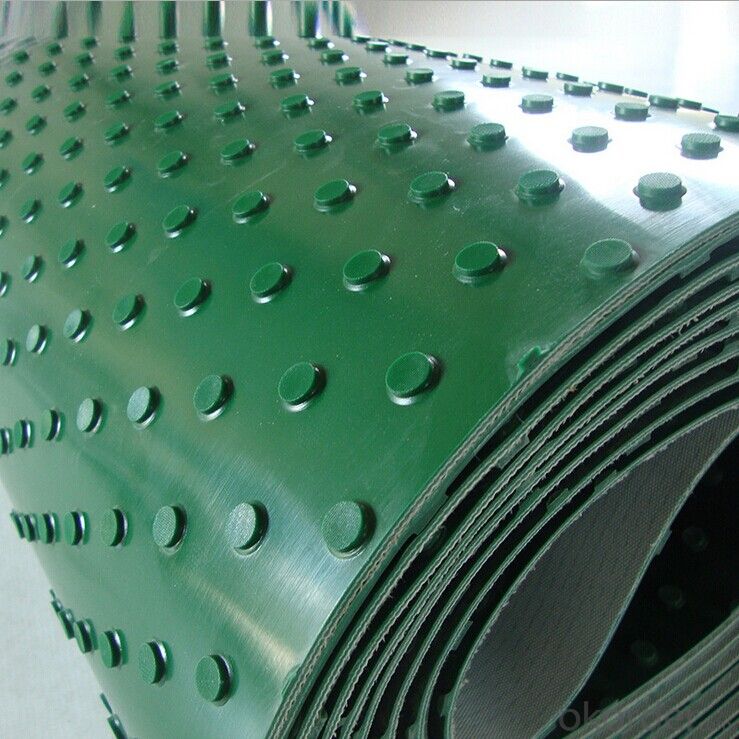

Characters:

1.High tensile strength, well circumnutate properties, light, thin, pliable but strong, oil resistant,non-toxicity,hygiene,easy clear.

2. Abrasion resistance,anti physical aging.

3. Acid/alkali resistant,cutting resistant,small turning radius.

4. It can be added V-type conducting bar underside and conducting bar or baffle on the surface.

5. Colors:white and green,etc.

6.Different thickness and width.

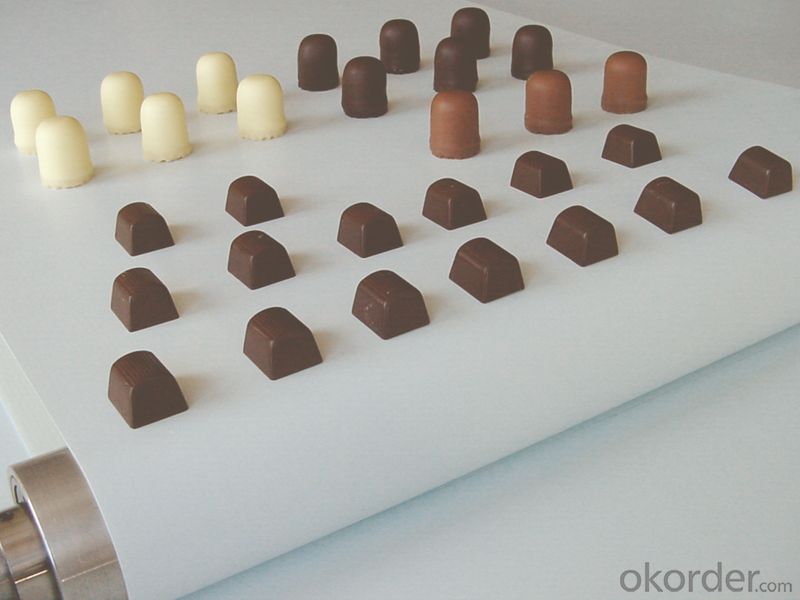

7.Appearance:high gross surface,matte,mainly used in food industry.

PVC/PU CONVEYOR BELT APPLICATION AREAS

Office automation equipments

Medical equipment

Packaging machinery

Swimming pool cleaning robots

Plotters

Money changers

Optical instruments

Robotic arms

Electric appliances

Vacuum systems

Vending machines

Food machinery

Textile machinery

DIY equipments

Pictures of PVC Conveyor Belt

RFQ:

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC treadmill conveyor belt, you could make an Inquiry in

okorder.com. Okorder.com provides you the products with best price and quality!

- Q: What solvent is used to clear the melted rubber layer?

- Remove the melted rubber layer with chloroform or toluene solvent.Rubber is a latex made from rubber, tree, rubber, and grass. It is made of flexible, insulating, impermeable and air. High elastic polymer compound. It is divided into two kinds: natural rubber and synthetic rubber. Natural rubber is made from rubber, tree, rubber, grass and other plants. The synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life.

- Q: What is the role of softening plasticizers in rubber? How are they classified?

- The plasticization of rubber can be done in a physical and chemical manner. The chemical plasticizer including the plasticizing plasticizing plasticizing process, which belongs to the rubber processing, internal plasticization in synthetic rubber, through the chemical reaction on the rubber chains into molecular structure flexibility, plasticity to achieve. Chemical plasticization will not be lost because of the volatilization or precipitation of plasticizing substances, and the plasticizing effect is long. Therefore, more and more attention has been paid to it. Physical plasticization refers to the purpose of increasing plasticity by means of additional substances. The term "plasticization" is usually referred to as physical plasticization, and the added substance in physical plasticization is called softening plasticizer.

- Q: How much is the recipe for Buddha's rubber?

- Rubber products were analyzed by infrared spectroscopy (FTIR), nuclear magnetic resonance (1H, NMR), mass spectrometry (MS), X diffraction analysis (XRD), ICP-MS, X fluorescence spectrometry, ion chromatography analysis, and other means. Through these testing methods can be a good solution for rubber products formulations, rubber products in the role of a detailed understanding of the more convenient for each enterprise research and development, grasp the market dynamics.

- Q: What are the common rubber products, please tell me

- Rubber products mainly include tires, sidewall, rubber strips and inner tubes, as well as parts of automobiles. They are made of wires, cables, wrapping and high voltage and extra high voltage insulating materials. They can also make rubber shoes and guardOther light colored products, such as raw materials, and other general industrial rubber products, cushioning materials, conveyor belts and belts, oil resistant hoses, gaskets, and chemical resistanceCorrosion equipment lining.

- Q: What is the definition of mixed rubber?

- Chemical property:Synthetic rubber is composed of different monomers under the action of the initiator, the polymerization of polymers of variety, monomer, styrene, butadiene acrylonitrile, isobutylene, chloroprene etc.. There are four kinds of polymerization process: emulsion polymerization, solution polymerization, suspension polymerization and bulk polymerization.

- Q: Rubber rolling process for making rubber products

- Rubber mastication is force, heat, oxygen or adding some chemical agents and other methods should be made by mechanical, rubber transition from elastic state for strengthening soft, easy processing of plastic process.Rubber mastication is designed to reduce its elasticity, increase the plasticity, and obtain adequate liquidity, mixing, rolling, extrusion, molding, curing and glue manufacturing, sponge and other manufacturing process to meet the requirements of.Mastering proper plasticity of plastic is essential to the processing of rubber products and the quality of finished products. The plastic degree should be reduced as much as possible in order to meet the requirements of processing technology. With the appearance of constant viscosity rubber and low viscosity rubber, some rubber is no longer need to be refined and mixed directly.

- Q: How does the rubber part of the watch become yellow?

- It is mainly divided into two kinds of natural rubber and synthetic rubber. Natural rubber is made from rubber, rubber and grass. Synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life. It has a wide range of uses. [1] can also be divided into rubber with natural rubber, general rubber, styrene butadiene rubber, nitrile rubber, silicone rubber, butadiene rubber, butyl rubber, EPDM rubber, chloroprene rubber types.

- Q: Natural rubber, general rubber, synthetic rubber. Are these all rubber products?

- General rubber is a big category, mainly refers to the general rubber tire manufacturing and commercial products of rubber, synthetic rubber production accounted for more than 50%, including styrene butadiene rubber, butyl rubber, EPDM rubber, chloroprene rubber etc..

- Q: What is food grade natural rubber?

- Is mainly made of natural rubber, made of natural rubber products, through the relevant national food contact using rubber testing standards, to reach the food grade.

- Q: What are the causes of the rubber products breach?

- Measures to prevent aging: from the point of view of aging, one of the main reasons is the polymer structure itself. Therefore, it is important to improve the structure of polymers to improve their aging ability. For example, in rubber vulcanization, there are still unsaturated double bonds, and rubber products in use and it is difficult to avoid the erosion of sunlight, oxygen, ozone, so people on the synthesis of new varieties, to avoid or reduce the polymer chain of rubber double bonds, such as ethylene and propylene two monomer by copolymerization made two yuan B two rubber, different from other synthetic rubber is one of the major characteristics in the structure of the backbone is not completely saturated with double bond, making it the most ozone resistance, chemical resistance, high temperature resistant rubber aging; there is a kind of antioxidant, such as adding oxygen or ozone to prevent aging caused by antioxidants. Add UV stabilizers, heat stabilizers, preservatives and other unfavorable factors, and caused by aging.

Send your message to us

Light Duty PVC Conveyor Belt with Punching Hole

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords