Fosse HDPE Geomembrane Black Plastic Sheeting

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

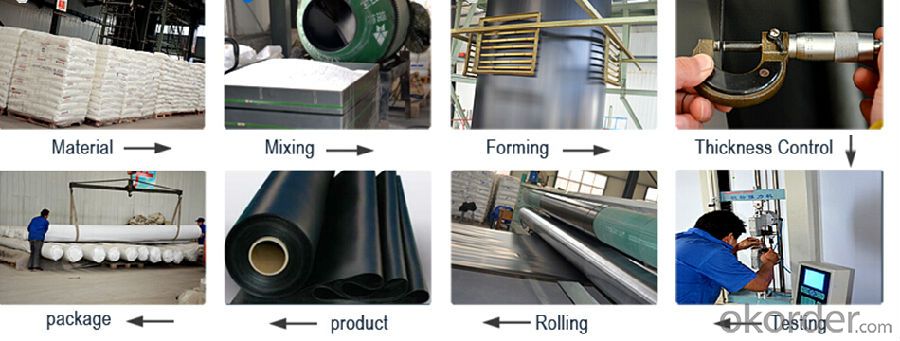

Type: | Geomembranes | Place of Origin: | Shandong, China (Mainland) | Brand Name: | CMAX |

Model Number: | JWGMPL | Material: | HDPE, LDPE, LLDPE | Thickness: | 0.2mm-4mm |

Business Type: | manufacturer, factory | Description: | chemical stabilized hdpe plastic membrane | Width: | 4m, 5.8m, 6m, 7m |

Feature: | uv and chemical resistant, long durability | Color: | Black, white, green | Surface: | smooth/textured/rough |

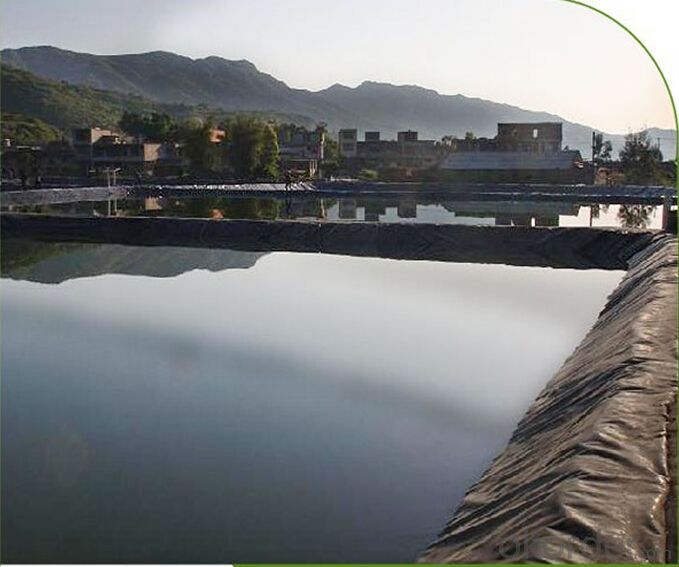

Application: | Pond, landfill, mine, salt farm, aquaculture, water reservoir |

Packaging & Delivery

Packaging Details: | hdpe geomembrane black plastic sheeting is packed in the woven bags. |

Delivery Detail: | Generally within 7 days for a 40ft container |

hdpe geomembrane black plastic sheeting

Our hdpe geomembrane plastic sheeting provide an impermeable barrier against

a wide range of solids and liquids.

They exhibit excellent chemical and UV resistance, impermeability, and high yield and welded

seam strengths, which is widely used.

Thickness | 0.2mm-4mm |

Width | 6m and 7m( or as your request) |

Length | 100m (or as your request) |

Color | white,black, green, double colored, etc |

Package | woven bags in normal |

Payment | T/T, L/C,Western Union, Paypal |

Application:

Solid Waste Landfill for secured dumping of Hazardous Waste.

Lining of Fly Ash ponds.

Thermal / Hydro power plant.

Dumping of Radio Active waste.

Masking of concrete structures at places like Port, Jetty, Bridge.

Spill containment for Chemical and Petrochemical Industries.

Industrial Reservoirs

Lining of Solar Evaporation Ponds / Sludge Ponds etc..

Foundation Lining, Floor Lining

FAQ

1. Can you send samples to us ?

Yes , free samples could be provided , but customer need pay for the freight cost .

After order placed , the freight charge could be refund .

2. What’s your Payment term ?

T/T , L/C , Western Union,Paypal ...

3. What’s your delivery method ?

By sea , By train , etc

4. What's your MOQ quantity ?

MOQ is one 20'container , the quantity could be negotiable

- Q: How are geomembranes used in pond liners?

- Geomembranes are used in pond liners to provide a durable and impermeable barrier that prevents water from seeping into the surrounding soil. This helps to maintain the water level in the pond, prevent erosion, and protect the environment from potential contamination.

- Q: Can geomembranes be used in transportation infrastructure?

- Yes, geomembranes can be used in transportation infrastructure. They are often employed in applications such as road and railway embankments, bridge abutments, and retaining walls to provide erosion control, slope stabilization, and moisture barrier functions. Additionally, geomembranes can be used in the construction of tunnels and culverts to prevent water infiltration and protect the structure from corrosion.

- Q: What are the precautions for the construction of the slope area of the cesspit?

- The construction method of geotextile/geomembrane: 1 flatness: ±2cm/m2, flat and straight; 2 compactness: 95%, after grinding, pave geomembrane on the surface; 3 vertical and horizontal gradient: Longitudinal and transverse slope should be above 2%, boundary and structure of the landfill bottom must be beneficial to diversion of leachate; 4 cleanness: No roots, rubble, gravel, concrete particles, such as sharp edges shall appear within vertical depth of 2.50cm . Climate requirements while paving: 1. Temperature: 5 - 40℃ is appropriate. Taking into account thermal expansion and cold contraction of the geomembrane, according to experience, when the weather is cold, geomembrane pavement should be tight; in hot weather should be loose; but it should be noted that, in summer, high temperature should be avoided at noon. 2 wind and rain: If the wind scale is over force 4 wind or it's raining, the construction should be stopped; When wind is lessened, it is proper to hold down geomembrane with sandbag so as to facilitate construction. Construction and installation of HDPE geomembrane: 1 construction and installation process of HDPE geomembrane. 2 tailor and transportation: According to the records of laying base measurement , cutting large bundle number of geomembrane should be marked and recorded and then carried to construction site according to their number.

- Q: What is a thin-film solar?

- The thin film solar cells with light weight and thin thickness. It can be bent andeasy to carry. Because conventional silicon cells made of silicon crystals, the main part of the battery fragile, prone to cracks invisible, mostly as a layer of protective glass, resulting in a large weight, portable inconvenience, poor seismic capacity, high cost, efficiency is more or less reduced. thin-film solar cells to overcome these shortcomings, but not the high conversion efficiency of traditional silicon cells. conversion efficiency of thin film solar cell to enhance solar technology sector is currently being studied the main direction as yet fully mature, large-scale production is still some risk, but is bound to play an important role in the field of solar energy whose development prospects are very promising.

- Q: What are the considerations for geomembrane installations in areas with high seismic activity?

- When installing geomembranes in areas with high seismic activity, several considerations need to be taken into account. Firstly, the geomembrane material should be selected based on its ability to withstand seismic forces and potential ground movements. High-quality, flexible geomembranes that can accommodate ground deformations are typically recommended. Secondly, the design and installation of the geomembrane system should include appropriate anchoring and attachment methods to ensure that the geomembrane remains in place during seismic events. This may involve using additional fastening techniques such as anchor trenches, concrete collars, or ballasting to secure the geomembrane. Thirdly, the subgrade preparation and compaction should be done meticulously to provide a stable base for the geomembrane. Proper compaction techniques and reinforcement measures, such as geotextiles or geogrids, can enhance the stability of the subgrade and reduce the potential for differential settlement or slope failure during seismic activity. Lastly, regular inspections and monitoring of the geomembrane system should be conducted to identify any signs of damage or displacement that could compromise its integrity. This can help ensure timely repairs or reinforcement to maintain the effectiveness of the geomembrane in high seismic areas. Overall, the considerations for geomembrane installations in areas with high seismic activity revolve around material selection, anchoring methods, subgrade preparation, and ongoing monitoring to ensure the long-term performance and stability of the geomembrane system.

- Q: Can geomembranes be used in stormwater infiltration and recharge systems?

- Yes, geomembranes can be used in stormwater infiltration and recharge systems. They serve as a barrier to prevent the loss of water through seepage and enhance the efficiency of the system by directing water to desired areas. Additionally, geomembranes help minimize the risk of groundwater contamination by preventing the infiltration of pollutants into the underlying soil.

- Q: Is PVC preservative film toxic?

- If PVC preservative film wrapped in the cooked food contact the oil on the surface of cooked food surface or it is put into the microwave oven for heating, the plasticiser in preservative film will have a chemical reaction with the food, and the volatilized toxins will penetrate into the food or reside on the surface of the food and, therefore, do harm to human health. Experts warn consumers that they should carefully select film products for food. In selecting preservative film, for the sake of safety, you should see if there is no product description, if it is marked with PE or polyethylene preservative film, you can use it; if it is marked with PVC or does not specify the material, then do not buy. You'd better reduce usage of preservative film and packaging bags with PVC, that is, polyvinyl chloride as the raw material. Businessmen have to pay more attention to this problem. If it is for heating in the microwave oven, even if it the raw material is not PVC, it can be used only if it is marked with the "suitable for microwave oven" on the outer package.

- Q: Should geotextile be laid under the geomembrane in the fish or shrimp ponds?

- It is completely unnecessary.

- Q: what is the film-drawing ceiling

- film-drawing ceiling introduction the film-drawing ceiling is introduced by foreign, which has ten performance and one hundred kinds of colors and fabrics with alternative, it is novel and beautiful, safe, durable, modelling diversity and quick installation, and suitable for any occasion. Scope of application: Home, apartment, office, workshop, conference room, computer room, hospital, school, cinema, hotel room, club, swimming pool, bathroom, Cara OK room, commercial premises, exhibition hall layout, etc.. Type 1, optical mask: It has strong light sensation, and can produce reflective effect similar to a mirror, it is mostly used for entertainment venues! 2, transparent film: It is milky white and translucent, the light transmission rate is 75%, and it can produce perfect and unique lighting decorative effect the lights, and it can be exclusively used in T4, T5 modulator tube and LED lamp. 3, Satin light film: It has fine stripes, the light perception ranks only second to optical mask, the overall effect is pure and elegant. 4, whale leather: The surface was villous, the overall effect is high-end, gorgeous, excellent sound absorption performance, which can create a warm interior effect. 5, metal surface: It has a strong metal texture, and can produce light metal, and has very strong ornamental effect. 6, pore membrane: The surface can be made of various specifications of small holes, light can play a variety of light through the hole! 7, mirror mask: There are white and yellow two colors and strong light sensation, which like a mirror. 8, painted film: There are marble, water and other kinds of patterns, it is translucent, and it will produce a good effect with light!

- Q: How do geomembranes protect against soil erosion?

- Geomembranes protect against soil erosion by acting as a physical barrier between the soil and external forces, such as water or wind. The impermeable nature of geomembranes prevents water from infiltrating the soil, reducing the risk of erosion caused by excessive rainfall or surface runoff. Additionally, geomembranes minimize the impact of wind by preventing the displacement of soil particles. Overall, geomembranes provide a protective layer that helps to maintain the stability and integrity of the soil, preventing erosion.

Send your message to us

Fosse HDPE Geomembrane Black Plastic Sheeting

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords