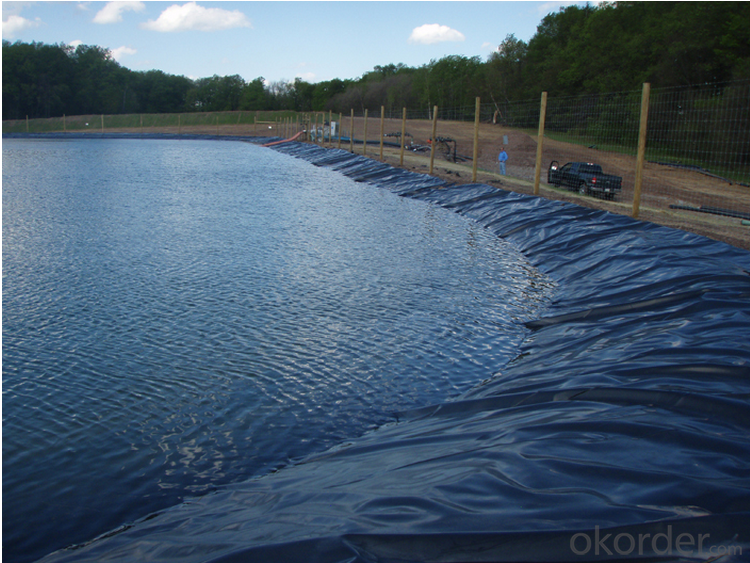

LLDPE Geomembrane Liner / Geocomposite / Composite Geomembrane / Geotextile Membrane / Waterproofing Membrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Characteristic

1.Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance, anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life.

2.Water, drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications and low cost, simple construction.

Table 1

Item | Specification | ||||||||

Nominal breaking Strength (KN/m) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

1 | Width Variation % | -1.0 | |||||||

2 | Breaking Strength KN/m≥ | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 |

3 | Elongation At Break (MD/CD)% | 30-100 | |||||||

4 | CBR Mullen Burst Strength KN≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | 3.2 |

5 | Hydraulic pressure /Mpa | As table 2 | |||||||

6 | Vertical Permeability Coefficient cm/s | According to request | |||||||

7 | Tear Strength KN≥ | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 |

8 | Peel strength (N/cm) | 6 | |||||||

Table 2

Item | Thickness of geomembrane/mm | ||||||||

0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | ||

Hydraulic Pressure/Mpa | Geotextile+ Geomembrane | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 |

Geotextile+ Geomembrane+Geotextile | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | |

Applicable scope

1) Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti- dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

FAQ

How about the delivery time?Lead time since receipt of 30% T/T deposit payment: 3 weeks.(Samples will be prepared within 3 days.)

2.What's are the MOQ?Generally speaking, the MOQ is one container, but we can provide you samples for quality inspection.

3. Do you charge for the samples?Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

4. Can you produce according to customers' design?Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: Is it worthwhile to stick membrane for high-end mobile phone?

- It is worthwhile for common cellphone but not for high-end mobile phone. The film for high-end mobile phone will be better than that of common mobile phone. But when sticking film, you need to see the cellphone material. Some mobile phone does not need to stick film, not to say that the high-end mobile phone film.

- Q: How is the geothermy film?

- The electrothermal?film efficiency will decrease with the usage rate year by year, so it is recommended that you should be better to use oil heater according to the size of your room. The service life of oil heater is longer than that of electrothermal?film and it is more practical than the electrothermal film. You can choose Xianfeng oil heater, which is cost-effective and professional.

- Q: where can i buy cheap geomembrane?

- Currently. Currently, good frost resistance performance,plastic film applied for seepage-proof at home and abroad, two films a cloth is in favor of the stability of protective layer and composite geo-membrane; vinyl copolymer (EVA). Corrosion resistance; and non-woven staple fiber is macromolecule staple fibre chemical material, mainly including polyvinyl chloride (PVC), polyethylene (PE), it's produced by the manufacturer according to individual requirements, low temperature resistance, various product specifications, there are many domestic geomembrane production manufacturers, ethylene & # 47 through needle stick or hot sticking forming, which is flexible material polymer chemistry, and because the rough non-woven surface, two cloth one film. Meanwhile, the base, etc., has high tensile strength and elongation, smaller proportion, strong extension, not afraid of acid, high?adaptability?to the?deformation, it can be also requested by the user according to their actual situation, and it can not only increase plastic film tensile strength and puncture resistance. The main mechanism is cutting off earth leakage passage with the imperviousness of plastic film, they have good corrosion resistance for bacteria and chemical function and has good chemical resistance, its tensile strength and elongation can withstand water pressure and adapt to dam deformation ; after it is combined with plastic film, increasing the friction coefficient of the contact surface; m2, etc., salt erosion, a cloth membrane, two cloth membrane and two cloth more and more film. Models include 200g & # 47 geomembrane takes plastic film as seepage-proof substrate, its seepage-proof performance depends on seepage-proof properties of plastic film and soil engineering impermeable material composed by non-woven cloth.

- Q: composite geo-membrane, two cloths and one membrane geomembrane 6 meters thick material how to use multiple sets of quotas

- 10 meters dam seepage-proof construction, 1000g composite membrane quotas are not accurate, depth 6 meters, each design Institute are not the same, two cloths one membrane composite membrane 800 grams per square meter is sufficient .

- Q: What is made of stretch film?

- As one of the synthetic resins, polyethylene has the largest production, mainly including low density polyethylene, linear low density polyethylene (LLDPE), high density polyethylene (HDPE) and some products with special performance.

- Q: What are the advantages of using geomembranes in floating baffles?

- The advantages of using geomembranes in floating baffles include their high strength and durability, resistance to chemical degradation, and ability to effectively contain and control water or other liquids. They are also flexible and easily customizable to fit different sizes and shapes, making them ideal for various applications. Additionally, geomembranes are relatively low maintenance, cost-effective, and environmentally friendly compared to other materials used in floating baffles.

- Q: How do geomembranes help in preventing land subsidence?

- Geomembranes help in preventing land subsidence by acting as a barrier between the ground and any underlying water sources. They are impermeable liners made of synthetic materials that prevent water from infiltrating into the soil. This prevents excessive saturation of the soil, which can lead to the weakening of the ground and subsequent subsidence. Additionally, geomembranes also provide stability and reinforcement to the soil, reducing the risk of subsidence caused by erosion or soil movement.

- Q: Does geomembrane has the color of grey?

- The color of the geomembrane is mostly black, and also green, white, gray, black green and other colors. The main material of geomembrane is high density polyethylene, auxiliary materials are antioxidants, anti UV agent, carbon black, masterbatch and so on, color of the geomembrane depending on the colour of added masterbatch. There is also geomembrane without auxiliary material, and it is transparent.

- Q: What is the cost of membrane structure?

- Membrane structure is a novel architectural form, compared with the traditional building materials, it has many advantages.

- Q: Can geomembranes be used in oil and gas storage applications?

- Yes, geomembranes can be used in oil and gas storage applications. Geomembranes are impermeable liners that are commonly used to contain and protect various types of liquids, including oil and gas. They are designed to provide a reliable barrier against leaks and contamination, making them suitable for storage tanks, secondary containment systems, and other oil and gas storage facilities.

Send your message to us

LLDPE Geomembrane Liner / Geocomposite / Composite Geomembrane / Geotextile Membrane / Waterproofing Membrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords