Pegamento Para Geomembrana de Alta Calidad PE/EVA/ECB

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000m2 m²

- Supply Capability:

- 3000 Tons Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

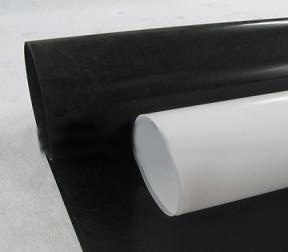

Introduction of PE/EVA/ECB Geomembrane:

Geomembrane including LDPE, LLDPE, HDPE, EVA, ECB and PVC geomembrane.

Application of PE/EVA/ECB Geomembrane:

Prevent leakage disposal in waste burying field, waste water, or waste dregs disposing field.

River bank, lake dam, mine remaining, reservoir, tunnel, liquid storage pool(pit, mine)

Preventing leakage of subway, basement, tunnel, holes

Anti-slot leakage in roadbed and other groundsill

The plan direction laying of dam, the vertical direction laying for groundsill, used in the construction fence and waste material field.

Used in seawater or freshwater feed field.

Used in groundsill of road, highway, railway and waterproof layer of swelling clay and wet collapsed loess.

Preventing leakage on rooftop

Specification of of PE/EVA/ECB Geomembrane:

|

Item |

Test Value | |||

|

EVA |

ECB |

PE | ||

|

Thickness(mm) |

0.2~4 | |||

|

Width(m) |

2.5~8 | |||

|

Tensile Strength at Break(Mpa) |

18 |

17 |

18 | |

|

Elongation at break(%) |

650 |

600 |

600 | |

|

Tear Strength(KN/M) |

100 |

95 |

95 | |

|

Impermeability(0.3MPa/24h) |

No Leakage | |||

|

Bending at low temperature(℃) |

-35 |

-35 |

-35 | |

|

Stretch tensor at heating(mm) |

≤Elongation |

2 |

2 |

2 |

|

≤Shrink |

6 |

6 |

6 | |

|

Air Oven Aging |

Tensile strength at break |

16 |

14 |

15 |

|

Elongation at Break |

600 |

550 |

550 | |

|

Anti-alkali(Saturated solution of Ca(OH)2 X 168H) |

Tensile strength at break |

17 |

16 |

16 |

|

Elongation at break |

600 |

600 |

550 | |

|

Nurture Weathering at manual Simulation |

Tensile strength at break retained % |

80 |

80 |

80 |

|

Elongation at break retained % |

70 |

70 |

70 | |

|

Puncture Strength |

1.5mm |

300 |

300 |

300 |

|

2.0mm |

400 |

400 |

400 | |

|

2.5mm |

500 |

500 |

500 | |

|

3.0mm |

600 |

600 |

600 | |

- Q: Can geomembranes be used for floating baffles?

- Yes, geomembranes can be used for floating baffles. They are often used as a cost-effective and efficient solution for creating floating baffles in various applications such as wastewater treatment, oil spills containment, and pond aeration. Geomembranes provide excellent chemical resistance, durability, and flexibility, making them suitable for constructing floating baffles that can effectively separate and control water flow.

- Q: How does the soft film ceiling?

- The soft film smallpox is the main choice of family ceiling in the markets of Europe and Russia , especially Russia, almost every Russian family use it. It should be said that it is the development trend of future indoor ceiling.

- Q: The pool of the soil, the loss and the number of lap

- This can discuss with the construction staff to decide how many centimeters,

- Q: What factors should be considered when selecting a geomembrane?

- When selecting a geomembrane, several factors should be considered. These include the type of application or project, the environmental conditions, the required lifespan and durability, the chemical compatibility with the surrounding materials, the installation and maintenance requirements, and the cost-effectiveness. Additionally, factors such as UV resistance, puncture resistance, flexibility, and ease of welding or seaming should also be taken into account. It is crucial to carefully assess these factors to ensure the chosen geomembrane meets the specific needs and demands of the project.

- Q: How are geomembranes used in construction projects?

- Geomembranes are used in construction projects as a protective barrier against water, chemicals, and other elements. They are often used to line landfills, ponds, and reservoirs to prevent leakage, as well as in underground construction to prevent groundwater contamination. Additionally, geomembranes are used in slope stabilization and erosion control to ensure the stability and longevity of structures.

- Q: Can geomembranes be used for landfill slope stabilization?

- Yes, geomembranes can be used for landfill slope stabilization. They are often used as a barrier to prevent erosion and control the movement of water within the landfill. Additionally, geomembranes can provide stability to the landfill slopes by reducing the risk of soil movement and slippage.

- Q: How are geomembranes tested for durability?

- Geomembranes are tested for durability through a combination of laboratory and field tests. In the lab, various mechanical tests, such as tensile strength and tear resistance, are conducted to evaluate their strength and resistance to external forces. Additionally, accelerated aging tests, like weathering and chemical exposure, are performed to simulate long-term environmental conditions. Field tests involve installing geomembranes in real-world applications and monitoring their performance over time, including their ability to withstand stress, deformation, and degradation. These comprehensive testing methods ensure that geomembranes are durable and can withstand challenging conditions in different environments.

- Q: Which mobile phone film is better? film or epidural?

- The film must be tempered or film, because the average hardness of the film is not mobile phone screen, the hardness is not enough not to protect, and the film is easy to draw, cause the screen light not. Toughened film hardness but with slightly larger screen is almost the same, but also posted a protective effect, but the film will affect the transmission is easy to leave fingerprints, the screen will dirty so or not to consider the film paste to paste, paste the best tempered film

- Q: What factors can affect the lifespan of a geomembrane?

- Several factors can affect the lifespan of a geomembrane, including the quality of the material used, the installation process, exposure to environmental conditions such as temperature and UV radiation, chemical exposure, and the level of maintenance and care given to the geomembrane.

- Q: What are the uses of geotextiles?

- Properties of geotextiles are as follows. 1. At present, geotextiles are made from synthetic fibers, namely the chinlon, dacron, polypropylene fiber and polyethylene fiber which all have high corrosion resistance. 2. Geotextiles are permeable. So they perform well in filtration and separation. 3. Because of the incompact structure, geotextiles perform well in dewatering. 4. Geotextiles have high anti-puncture ability. So they perform well in protection. 5. Geotextiles have high friction coefficient and strength of extension which means they can be used for reinforcement.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1998 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port,China |

| Export Percentage | 41-50% |

| No.of Employees in Trade Department | 5-10 People |

| Language Spoken: | English; Chinese; Russian; Spanish |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Pegamento Para Geomembrana de Alta Calidad PE/EVA/ECB

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000m2 m²

- Supply Capability:

- 3000 Tons Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords