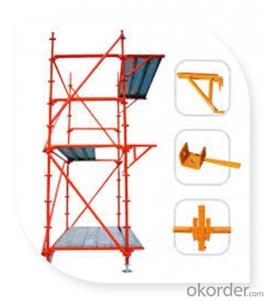

Kwikstage Scaffolding System Used in Construction CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Kwikstage Scaffolding System Used in Construction

Type:

Material:

Construction Properties:

Lapping Form:

Framework:

Supporting Mode:

Erection Position:

Scaffolding Part Type:

Move Method:

Structural Style:

Place of Origin:

Surface:

Material.:

Thickness:

Descriptions of Kwikstage Scaffolding System Used in Construction

Kwikstage Scaffolding is a multi-purpose modular scaffold system which can be used for all forms of access and support structures in the building and construction industries, ship buliding, offshore construction and industrial maintennace.

Details of Metal kwikstage Scaffolding

1. Metal kwikstage scaffolding system is a new type of selflock scaffolding which is very popular in Oceanian,African construction.

2. Metal kwikstage scaffolding System is suitable for both inside concrete slab supporting and outside masonry Construction multi-purpose for construction.

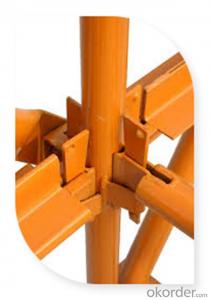

3. Metal kwikstage scaffolding systemstandard is weld with a plate every 600mm which can join ledgers at 90 degree.

4. Metal kwikstage scaffolding system ledger is a horizontal member with a blade at each end for insertion into the standard plate.

5. kwikstage scaffolding system is quick to erect and strip which has completely replaced other scaffolding.

The Accessories of Descriptions of Kwikstage Scaffolding System Used in Construction

STEEL STANDARD

Material: steel tube φ48.3x3.25mm

Surface finish: hot dipped galvanized

Standard with normal length 3.0m, 17.02kg

Standard with normal length 2.5m, 14.32kg

Standard with normal length 2.0m, 11.64kg

Standard with normal length 1.5m, 8.94kg

Standard with normal length 1.0m, 6.26kg

Standard with normal length 0.5m, 3.56kg

Topper Standard, 1.72kg

Material: steel tube φ48.3x4.0mm

Surface finish: hot dipped galvanized

Standard with normal length 3.0m, 19.48kg

Standard with normal length 2.5m, 16.38kg

Standard with normal length 2.0m, 13.28kg

Standard with normal length 1.5m, 10.18kg

Standard with normal length 1.0m, 7.07kg

Standard with normal length 0.5m, 3.97kg

Topper Standard, 1.93kg

STEEL LEDGER

Material: Made of steel tube φ48.3x3.25mm

Surface: hot dipped galvanized

Ledger of 3.00m, 13.00kg

Ledger of 2.44m, 10.67kg

Ledger of 2.39m, 10.60kg

Ledger of 1.95m, 8.87kg

Ledger of 1.83m, 8.29kg

Ledger of 1.78m, 8.20kg

Ledger of 1.47m, 6.97kg

Ledger of 1.22m, 5.98kg

Ledger of 1.05m, 5.31kg

Ledger of 0.71m, 3.97kg

TRANSOM (ANGLE)

Material: Made of steel 5# angle

Surface: hot dipped galvanized

Transom 2.39m, 17.71kg

Transom 1.78m, 13.60kg

Transom 1.27m, 10.19kg

Transom 1.22m, 9.85kg

Transom 1.05m, 8.70kg

Transom 0.813m, 7.12kg

Transom 0.71m, 6.42kg

Transom 0.60m, 5.75kg

Transom 0.51m, 5.08kg

L/A Transom 1.8m, 11.78kg

L/A Transom 1.2m, 9.56kg

BRACE

Material: Made of steel tube φ48.3x3.25mm

Surface: hot dipped galvanized

Brace 3.6m, 15.33kg

Brace 3.2m, 14.00kg

Brace 2.7m, 12.25kg

Brace 2.0m, 9.33kg

Brace 1.6m, 7.99kg

STEEL PLANK

Material: Made of 1.8mm thickness pre-gal.steel sheet

Surface: hot dipped galvanized

Size: 229mm(W)x 66mm(H)

Steel Plank 4.00m, 25.30kg

Steel Plank 3.00m, 18.90kg

Steel Plank 2.44m, 15.37kg

Steel Plank 2.00m, 12.52kg

Steel Plank 1.81m, 11.42kg

Steel Plank 1.25m, 8.20kg

Steel Plank 1.05m, 7.05kg

Steel Plank 0.736m, 5.25kg

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: I'm gonna be getting piercings this weekend, so i know im already getting my nose. but i want to get my ear. like barbell? so what's the difference between Scaffold and Industrial?

- Theres no difference scaffold is what they call it in like europe, indusstrial is usa

- Q: Standard for inspection of portal scaffolding

- The inspection results are summarized in table NO:2008JW1658 serial number of inspection items and standard units of measurement test results 1# 2# single judge 1 Materials: 1.1 qualified door frame and accessories in addition to special requirements, the material should be consistent with the provisions of the Q235 according to GB/T 700

- Q: i have lived in york for ten years and have been told many times that the minster in york has had scaffolding up for decades and that it has to stay there for political or religious reason there is never any work done or indeed workers on the scaffolding. can anyone shed any light on the matter for me or is it just an urban myth and nothing more than on going restoration.

- York Minster Scaffolding

- Q: What are the dangers of scaffolding

- Analysis of the types of scaffolding accidents1) the entire frame dumping or local collapse frame2) the whole frame instability and vertical collapse3) personnel from scaffold falling

- Q: If you have two workers say standing on a scaffolding, their are downward forces from the weight of the workers along with the weight of the scaffold, and upward forces from tension suspending the scaffolding in place. The opposite forces add to zero and thus the scaffolding remains at rest.My question has to do with what would occur if more/less workers were on the scaffolding. It appears to me that the scaffolding would always remain at rest. Would there always be a ΣF=0 regardless of the amount of workers? As the decreases in weight from removing a worker would also cause the tension force to be weaker? And vice versa if there were more workers?I

- You are correct so long as the scaffolding is not allowed to move. I.e. the cables suspending it are locked and not unwinding from their spools as more workers get on. More weight added would necessarily increase the tension in this type of case. However, if, when another worker got on and the tension could not increase for what ever reason, a downward acceleration would take place that is proportional to the worker's weight. Hope that clears things up.

- Q: What are the requirements for the sampling inspection of scaffolding?

- Quality specification for the cantilever support1 the material of the suspension bearing frame should have the certificate of quality and quality inspection report;2 the height and length of the weld shall meet the design requirements, and shall not have any defects such as welding cracks, structural deformation, corrosion and so on;3 the production quality of the suspension frame shall be in conformity with the provisions of appendix D table D.1.

- Q: Fastener type steel pipe scaffold composed of two components? What are the roles?

- Bowl buckle steel pipe scaffolding when using steel pipe, as a "single steel pipe scaffolding"; when using the steel cross bar, for the "steel pipe based scaffold".2.2 according to the vertical and horizontal transmission force between the vertical and horizontal1) the frictional force acting on the contact surface. That is, the friction force at the contact surface of the joint is pressed to support the load of the cross bar and is transmitted to the vertical rod;2) welding force. Most of the cross bar and vertical rod socket connection is used in this way, the door frame is also this way;3) direct pressure transmission. This method is more common in the horizontal bar placed in the top of the scaffolding;4) shear force of pin. That is to say, the connecting rod and the hole of the vertical rod are connected by the pin rod through the vertical connecting plate of the transverse rod to realize the double side shear action of the connecting rod and the pin rod. This method is rarely seen in the connection between the rod and the vertical rod.

- Q: I would like to ask how much scaffolding steel prices, scaffolding steel pipe use what are the requirements?

- General price of 3800-4200 yuan per ton, you need to see the material and specifications.1. Scaffolding steel pipe material Q195, Q215 or Q2352. Scaffolding steel pipe specifications of 3, phi, phi, phi, phi, phi, phi, 2.5, phi = phi, phi, phi, phi, phi, phi, phi, phi, 3.25, Phi3. Scaffolding steel pipe length of 1-6 meters, half a meter specifications can be customized according to customer specifications4. Scaffolding steel pipe standard SY/T5768-95 GB/T3091-2001

- Q: i had my scaffold piercing done in the summer holidays and wen i went back to school (currently in my last year) they told me to take it out so i had to go back to the piercer. They changed the bar to two clear retainers in the holes so they wouldn't heal, now it hurts all the time and is red with a bubble on the top of my ear, any suggestions as to what i should do? :/

- try drying it out with sea salt soaks, tea tree oil, aspirin paste (crushed aspirin and water) , chamomile tea bag soaks !!! keloids are unpredictable , you can get them anytime from changing the jewelry early, irritation, bumping it on stuff or accidentally yanking it , and they will either stay or go away !!! you can prevent infections by cleaning the piercing regularly with anti bacterial soap and sea salt soaks , making sure to use clean hands when handling the piercing and not letting anyone touch the piercing

- Q: Okay so I got a scaffold piercing about 5 days ago now. I've been cleaning it with Claire's piercing stuff. What I do is I pour it onto a little bit of loo roll and squeeze it all out on where the holes are. I have not been twisting it at all, but my friend told me that I should soak it in warm salty water and twist it twice a day. I have no idea what to do now as I have researched it and some people say that I shouldn't twist it because it will drag more bacteria into it and could get it infected. Also I have massive scabs around both ends of the bar, I've tried to pick them off as they are pretty uncomfortable, but it didn't work as they are rock solid, so how do I get these off? I have no idea what to do, my piercer didn't say anything about twisting it just cleaning it twice a day. Oh and if it helps I'm 13:) Thanks. X

- Why are you using Claire's crap? You need to be doing sea salt soaks twice a day for 5-10 minutes each soak with 1/4th of a teaspoon of non-iodized sea salt to 8oz of hot water. Don't twist them as that drags in crust and bacteria and tears up the inside of the piercing. Stop trying to pick stuff off from your ear and go have a reputable piercer check out the scabbing, it could be crust it could be something wrong. If your piercer didn't tell you to do sea salt soaks to keep it clean go to a better piercer.

Send your message to us

Kwikstage Scaffolding System Used in Construction CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords