Metal Kwikstage Scaffold System for Building Construction Project CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Metal Kwikstage Scaffold System for Building Construction Project

Type:

Material:

Construction Properties:

Lapping Form:

Framework:

Supporting Mode:

Erection Position:

Scaffolding Part Type:

Move Method:

Structural Style:

Place of Origin:

Surface:

Material.:

Thickness:

Descriptions of Metal Kwikstage Scaffold System for Building Construction Project

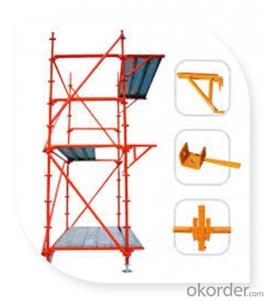

Kwikstage Scaffolding is a multi-purpose modular scaffold system which can be used for all forms of access and support structures in the building and construction industries, ship buliding, offshore construction and industrial maintennace.

Details of Metal kwikstage Scaffolding

1. Metal kwikstage scaffolding system is a new type of selflock scaffolding which is very popular in Oceanian,African construction.

2. Metal kwikstage scaffolding System is suitable for both inside concrete slab supporting and outside masonry Construction multi-purpose for construction.

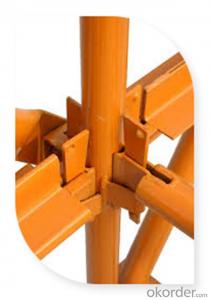

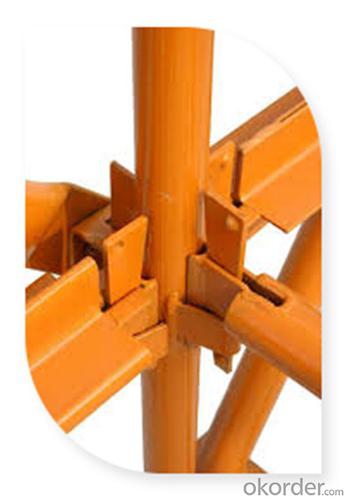

3. Metal kwikstage scaffolding systemstandard is weld with a plate every 600mm which can join ledgers at 90 degree.

4. Metal kwikstage scaffolding system ledger is a horizontal member with a blade at each end for insertion into the standard plate.

5. kwikstage scaffolding system is quick to erect and strip which has completely replaced other scaffolding.

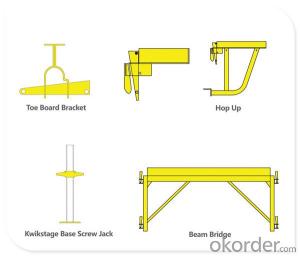

The Accessories of Metal Kwikstage Scaffold System for Building Construction Project

The main items of Kwikstage scaffolding system

ITEMS SPECIFICATION WEIGHT STANDARD

(VERTICAL)48.3*4.0*3000/2500/2000/1500/1000mm

painted/hot dip galvanized/ect.

steel pipe16.94/14.34/11.53/8.86/6.13kg LEDGER

(HORIZONTAL)48.3*3.2*2400/1800/1200/700mm

painted/hot dip galvanized/etc.

steel pipe9.1/6.85/5.13/3.24kg TRANSOM 2400/1800/1200/700mm

painted/hot dip galvanized/etc.19.92/12.08/10.79/7.79kg BRACE 2400*2000mm/2500/3000mm

pained/hot dip galvanized/etc.9.38/10.35/11.41kg HOPUP BRACKET one board/two board/three board

painted/hot dip galvanized/etc.1.84/4.99/8.58kg The other items of Kwikstage scaffolding system

TIE BAR 2400/1800/1200/700mm

painted/hot dip galvanized/etc.5.41/4.15/2.77/1.72kg STEEL BOARD 2400/1800/1200/700mm

painted/hot dip galvanized/etc.14.5/10.93/7.68/4.94kg END TOE BOARD BRACKET as normal specification or as customers' drawing

painted/hot dip galvanized/etc.1.12kg TOE BOARD BRACKET as normal specification or as customers' drawing

painted/hot dip galvanized/etc.0.72kg BASE JACK and U HEAD 38*4.0*650mm/u head

painted/hot dip galvanized/etc.3.69/4.63kg FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: What are the characteristics of disc scaffolding

- The Pankou scaffolding 60 heavy support frame as an example, the height of 5 meters of the single pole of the allowable bearing capacity of 9.5 tons, the failure load reached 19 tons, is 2-3 times of traditional products. Advanced technology: disc scaffolding connection disc to the rod force through the center node is mainly used in Europe, countries and regions, is the rise in price replacement products, the scaffold is firm, stable structure of disc type scaffold material upgrade: the main materials used in low alloy structural steel (GB Q345), strength higher than the traditional carbon steel tube scaffold (GB Q235) 1.5-2 times

- Q: Key points for safety of portal scaffolding

- The main points of the safety of portal scaffolding1, scaffold erection must be held by professional Jia Zigong, and according to the current national standard "special operations personnel safety assessment management rules" (GB5036) qualification certificates. Staff should conduct regular physical examination, which is not suitable for high operator, not on the scaffold.

- Q: Room 29 meters outside the wall of the two rows of steel pipe scaffolding installation, demolition, joint protection measures in Wuhan, the price per square is how much money? A friend to help refer to Kazakhstan

- With regard to the design and construction of floor type (double pole type) single and double row steel pipe scaffold for industrial and civil construction, and the design and construction of formwork support in the construction of horizontal concrete structure. National compulsory technical norms, because of its complexity, and you proposed "one square meter standard steel scaffolding the number of meters" is a vague and unclear description of the problem, considering the matter of security,

- Q: Every time someone in medieval times was murdered by the beheading a new scaffold was built for the next prisoner.

- Well that's not entirely true; they didn't ALWAYS built a new scaffold. Probably movies let you think so but that was not the case.

- Q: Fastener type steel pipe scaffold composed of two components? What are the roles?

- Bowl buckle steel pipe scaffolding when using steel pipe, as a "single steel pipe scaffolding"; when using the steel cross bar, for the "steel pipe based scaffold".2.2 according to the vertical and horizontal transmission force between the vertical and horizontal1) the frictional force acting on the contact surface. That is, the friction force at the contact surface of the joint is pressed to support the load of the cross bar and is transmitted to the vertical rod;2) welding force. Most of the cross bar and vertical rod socket connection is used in this way, the door frame is also this way;3) direct pressure transmission. This method is more common in the horizontal bar placed in the top of the scaffolding;4) shear force of pin. That is to say, the connecting rod and the hole of the vertical rod are connected by the pin rod through the vertical connecting plate of the transverse rod to realize the double side shear action of the connecting rod and the pin rod. This method is rarely seen in the connection between the rod and the vertical rod.

- Q: Im 18 years old and maleI have 4 piercings. On my left I have my lobe and a double helix (a type of cartilage piercing). On my right I have a scaffold/industrial. I know I want another piercing on my right ear, but cant decide what to get. Any input is greatly appreciated.

- conch would look great and not make it look to cluttered go for it :)

- Q: I really want to get one done and I would like it if someone could tell me how badly does it really hurt? During and after. I know everybody has different pain thresholds but on average? I'm just nervous to get it done but really want another piercing on my ears. I have my lobes and a cartilage on my right ear. How easy is it to clean? rate in numbers as well as a description. Thanks.

- My lip piercing did not harm in any respect. i've got not got an anti-tragus piercing, yet I do have a ordinary tragus piercing and that harm even under the lip. To be elementary, they are the two very tolerable. My navel piercing harm better than the two one in each of them.

- Q: Electric basket accessories are generic

- Electric basket full name is called electric gondola, the construction of electric basket is mainly suitable for high-rise buildings on the electric power from the electric hoist special basket, basket accessories have what those:

- Q: A 67.0- painter is on a uniform 21- scaffold supported from above by ropes. There is a 3.8- pail of paint to one side. The ropes are 1m inside the scaffold on each side. The pail is 1m away from the left rope and 3m from the right rope. The scaffold is a 6m. How close to the right end can he approach safely? How close to the left end can he approach safely?

- First of all...no units, no answer. Second of all...according to OSHA (Occupation Safety and Health Administration), NO ONE can walk on a scaffold beam outside the support ropes OR SET ANY OBJECT DOWN outside the support ropes. Hence the answers for both questions are 1 meter. It doesn't matter what a calculation will yield...NO ONE can walk on the beam outside the support ropes safely. Even if a torque balance yields that it will not put the ropes in compression and buckle them...it still isn't considered to be safe by OSHA if the painter is outside the ropes.

- Q: How to calculate the vertical force of scaffolding

- The calculated data include the following three values:1 uniform load value calculation,2 bending strength calculation: the maximum bending moment is considered as the moment under the uniform load3 deflection calculation: the maximum deflection is considered as the deflection of simply supported beam under uniform load

Send your message to us

Metal Kwikstage Scaffold System for Building Construction Project CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords