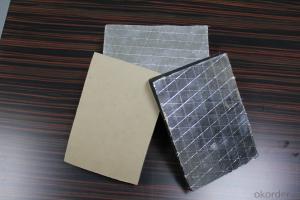

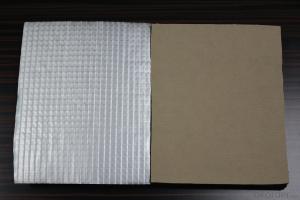

Kraft Paper Faced Rubber Insulation with Aluminum Foil Facing

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

CMAX Rubber Plastic Product advantages:

Fire-blocking, Low Conductivity factor, Good pliability, Closed pore foaming, Good damp-proof property, Vibration resistance, Easy to install and beautiful appearance

| Item | Unit | Specification | Standard | |

| Density | Kg/m³ | ≤95 | GB/T6343 | |

| Oxygen index | % | ≥32 | GB/T2406 | |

| Flammability | SDR | —— | ≤75 | GB/T8627 |

| Conductivity factor | W/(m.k) | |||

| Average temperature | ||||

| -20°C | ≤0.031 | GB/T10294 | ||

| 0°C | ≤0.034 | |||

| 40°C | ≤0.036 | |||

| Watervapor permeability | Coefficient | g/(m.s.pa) | ≤2.8*10-11 | GB/T17146-1997 |

| Factor | —— | ≥7.0*10³ | ||

| Water absorption ratio in vacuum | % | ≤10 | GB/T17794-2008 | |

| Dimension stability | % | ≤10 | GB/T8811 | |

| 105±3°C,7d | ||||

| Crack resistance | N/cm | ≥2.5 | GB/T10808 | |

| Compression resilience ratio | % | ≥70 | GB/T6669-2001 | |

| Compression time 72h | ||||

| Anti-ozone | —— | Not cracking | GB/T7762 | |

| Ozone pressure 202mpa | ||||

| 200h | ||||

| Aging resistance | —— | Slightly crumpling, | GB/T16259 | |

| 150h | no cracks, | |||

| Temperature | °C | -40°C——110°C | GB/T17794 | |

- Q: Is it possible to use aluminum foil with a reflective side to cover leftover food?

- <p>Yes, aluminum foil facing can be used to wrap leftovers. The reflective side of aluminum foil is often used for its heat-reflective properties in cooking, but it is also suitable for wrapping and storing leftovers. It provides a barrier to air, helping to keep food fresh and preventing freezer burn if used in the freezer. However, it's important to ensure that the foil is tightly sealed around the food to maintain its freshness and prevent contamination.</p>

- Q: This question asks for methods to prevent metal shavings from contaminating food when using aluminum foil.

- <p>To avoid getting metal shavings into your food when using aluminum foil facing, always handle the foil carefully to minimize tearing or scratching. Use a sharp knife or scissors to cut the foil, ensuring clean edges. Avoid using foil that is damaged or has sharp edges. When placing food on the foil, ensure the foil is smooth and free of any loose particles. Do not use foil with a non-stick surface for direct contact with acidic, salty, or high-sodium foods as it can cause the foil to break down. Finally, consider using heavy-duty aluminum foil which is thicker and less likely to produce shavings.</p>

- Q: This question asks for the most suitable materials to be used in conjunction with aluminum foil facing.

- <p>The best materials to use with aluminum foil facing are those that are compatible with its properties. For insulation, materials like fiberglass or polyethylene foam are ideal due to their thermal resistance. For construction, materials such as plywood or drywall can be used as a backing, as they provide a sturdy base. When it comes to sealing, materials like butyl rubber or silicone are effective because they adhere well to aluminum foil and create a watertight seal. It's crucial to select materials that won't react chemically with aluminum and can withstand the environmental conditions in which the foil facing will be used.</p>

- Q: This question asks for signs or methods to identify if the aluminum foil facing of a product, such as insulation or a jacket, is damaged or defective.

- <p>To determine if your aluminum foil facing is damaged or defective, look for visible signs such as tears, punctures, or holes. Check for any discoloration or rust, which could indicate corrosion. The foil should be smooth and uniform; any irregularities or bubbling might suggest a defect. Additionally, test the integrity by gently pulling or pressing the foil鈥攊f it easily tears or crumples, it may be compromised. For insulation, a damaged foil facing can lead to reduced effectiveness in heat or cold retention, so also consider the performance of the item.</p>

- Q: Is it safe and effective to use aluminum foil with a reflective side for baking purposes?

- <p>Yes, aluminum foil facing can be used for baking. The shiny side of aluminum foil is often used to cover baking dishes to prevent food from drying out, to create a steam effect, or to reflect heat for even cooking. However, it's important to avoid direct contact between the foil and the heating elements of the oven to prevent fire hazards. Always follow the manufacturer's guidelines for safe use and placement of aluminum foil in your oven.</p>

- Q: Is it possible to use aluminum foil facing as a material for creating a potpourri sachet?

- <p>Yes, you can use aluminum foil facing to make a potpourri sachet. Aluminum foil is a versatile material that can be cut into small squares or shapes and filled with dried flowers, herbs, and spices to create a fragrant sachet. Ensure the foil is clean and free from any oils or residues before use. Seal the edges of the foil to prevent the contents from spilling out. While it's not as breathable as fabric, it can still hold the scent and keep the potpourri fresh.</p>

- Q: What are the potential health hazards related to using paper plates in comparison to aluminum foil facing?

- <p>There are generally no significant health risks associated with using paper plates instead of aluminum foil facing. Paper plates are made from food-grade materials and are designed to be safe for contact with food. However, it's important to ensure that the paper plates are free from any harmful chemicals or dyes, and are not contaminated during production or storage. Aluminum foil facing, when used properly, is also safe, but it can leach aluminum into food if heated excessively or used with acidic foods. Both options are generally considered safe, but it's always best to use products from reputable manufacturers and follow usage guidelines.</p>

- Q: Is it possible to use aluminum foil as a baking surface? If yes, what kinds of foods are suitable for baking with aluminum foil?

- <p>Yes, aluminum foil can be used for baking. It's particularly useful for foods that require even heat distribution or need to be shielded from direct heat, such as delicate pastries, fish, or vegetables. It can also be used to prevent food from sticking to the baking sheet or to catch any drips, making cleanup easier. However, it's important to note that some foods, especially those with a high sugar content, can burn if they come into direct contact with the foil, so it's best to use it with a light layer of oil or parchment paper underneath.</p>

- Q: The user is asking if aluminum foil can be used as a replacement for tin foil in baking and grilling applications.

- <p>Yes, you can use aluminum foil as a substitute for tin foil in baking pans or grilling pans. Both aluminum and tin foil are commonly used for similar purposes, such as lining pans, wrapping food, and preventing food from sticking. Aluminum foil is more widely available and less expensive than tin foil. It conducts heat well and is non-toxic, making it a suitable alternative for most baking and grilling needs. However, note that aluminum may react with acidic foods, so it's best to avoid using it in such cases or to use a heavier gauge to minimize contact with the food.</p>

- Q: Explain the differences between thin and thick aluminum foil facing in terms of thickness, durability, and usage.

- <p>Thin aluminum foil facing is characterized by its low thickness, which makes it flexible and easy to handle but less durable. It's commonly used for wrapping food, baking, and protecting surfaces. Thick aluminum foil facing, on the other hand, is more robust and tear-resistant, suitable for heavy-duty applications such as construction, insulation, and packaging. The thicker material offers better protection and durability, but it's less pliable and can be more challenging to work with.</p>

Send your message to us

Kraft Paper Faced Rubber Insulation with Aluminum Foil Facing

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords