High Quality Closed Cell Flexible Rubber Plastic Foam with Aluminum Foil Facing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Flexible Rubber Plastic Insulation Material Description

rubber plastic is a high quality heat-insulating and heat-preservation material which use butyronitrile rubber and polyvinychloride(NBR,PVC) as main raw materials.

The productionprocess includes mixing, tensing and continuous extruding , heating andfoaming, cooling and cutting.

2.Main Features of Rubber Plastic

-Lower heat-conductivity

-Higher fire-blockingperformance

-Damp-proof andWater-proof

-Softness

-Neat and

-Easy to installeasy handing and storage

-Good flexibilityand tenacity

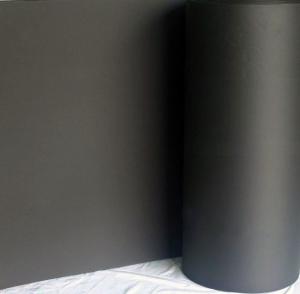

3.Rubber Plastic Images

4.Rubber Plastic Specification

--Rubber Plastic Sheet

Density(kg/m3) | 40-90 | ||||

Thickness(mm) | 10 mm | 15 mm | 20 mm | 25 mm | 30 mm |

Length (m) | 20 | 20 | 10 | 10 | 10 |

Width (m) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of HVAC materials,is one of the large-scale professional investment building materials production bases in China.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What distinguishes various grades of aluminum foil sheets from one another?

- <p>Different grades of aluminum foil sheets are distinguished by their thickness, strength, and purity. Grade 1 is the purest and softest, used for food wrapping and baking. Grade 2 is harder and more tear-resistant, suitable for heavy-duty use like grilling. Grade 3 is an alloy and offers high strength and durability, often used in industrial applications. Grade 4 is a heat-treatable alloy, providing high strength and used in aerospace and automotive industries. Each grade has specific applications based on its unique properties.</p>

- Q: What is the function or use of aluminum foil facing in construction or insulation?

- <p>Aluminum foil facing is used primarily for thermal insulation in construction and HVAC systems. It reflects radiant heat, reducing heat transfer and improving energy efficiency. It also serves as a vapor barrier, preventing moisture from passing through insulation, which can reduce its effectiveness. Additionally, aluminum foil facing can provide a clean, finished appearance and protect the insulation material from damage and contamination.</p>

- Q: This question asks for methods to prevent metal shavings from contaminating food when using aluminum foil.

- <p>To avoid getting metal shavings into your food when using aluminum foil facing, always handle the foil carefully to minimize tearing or scratching. Use a sharp knife or scissors to cut the foil, ensuring clean edges. Avoid using foil that is damaged or has sharp edges. When placing food on the foil, ensure the foil is smooth and free of any loose particles. Do not use foil with a non-stick surface for direct contact with acidic, salty, or high-sodium foods as it can cause the foil to break down. Finally, consider using heavy-duty aluminum foil which is thicker and less likely to produce shavings.</p>

- Q: What distinguishes aluminum foil facing from other types of facing materials?

- <p>Aluminum foil facing is a type of facing material that uses a thin layer of aluminum, known for its excellent barrier properties against air, moisture, and light. This makes it ideal for insulation and packaging applications where preservation of contents is crucial. In contrast, other types of facings, such as paper, fabric, or plastic, may not offer the same level of barrier protection. Paper facings are often used for their aesthetic appeal and are more breathable, while fabric facings provide flexibility and are used for applications requiring durability and comfort. Plastic facings can be waterproof and are used where a shiny or smooth surface is desired. Each type of facing has unique properties that make it suitable for specific applications, with aluminum foil facing being particularly notable for its barrier capabilities.</p>

- Q: How should aluminum foil be stored after it has been used for cooking or food storage to keep it clean and ready for future use?

- <p>The best ways to store aluminum foil facing after using it for cooking or food storage involve cleaning and organizing it properly. First, wash the used foil with warm soapy water to remove any food residue. Rinse it thoroughly and pat dry with a clean towel. To store, roll the foil tightly starting from the center, keeping it compact and neat. Alternatively, you can store it in a resealable plastic bag or a dedicated foil container to keep it clean and prevent it from tearing. Always store it in a cool, dry place away from direct sunlight to maintain its quality.</p>

- Q: This question asks for the steps to prepare aluminum foil for cooking, specifically how to set it up.

- <p>To prepare aluminum foil facing for cooking, first, cut a piece of aluminum foil larger than the cooking surface. Clean the foil to remove any dust or debris. Lightly grease the foil with cooking spray or oil to prevent food from sticking. Fold the edges of the foil up to create a shallow tray, ensuring the sides are high enough to contain any juices. Place the foil on the cooking surface, and you're ready to cook. Always handle the foil with utensils when hot to avoid burns.</p>

- Q: This question asks for methods to clean oil stains from the aluminum foil facing of a surface.

- <p>To remove oil stains from aluminum foil facing, start by scraping off any excess oil with a plastic scraper or a butter knife. Then, mix a solution of warm water and dish soap. Apply the solution to the stained area and let it sit for a few minutes. Use a soft cloth or sponge to gently scrub the area. Rinse with warm water and dry thoroughly. For stubborn stains, you can use a mixture of baking soda and water to create a paste, apply it to the stain, let it sit for 15 minutes, then scrub and rinse. Always test cleaning methods on a small, inconspicuous area first to ensure no damage occurs.</p>

- Q: Is there a concern that aluminum from aluminum foil can seep into food during cooking or storage?

- <p>There is minimal risk of aluminum leaching from aluminum foil into food. Aluminum foil is generally safe for cooking and food storage when used properly. The risk increases with acidic or alkaline foods and high temperatures, but under normal cooking conditions, the amount of aluminum that could leach is negligible. However, it's best to avoid wrapping food in aluminum foil for long periods or at very high temperatures to minimize any potential exposure.</p>

- Q: This question asks about the various types of aluminum foil facing used in construction and insulation materials.

- <p>Aluminum foil facing is used in various applications, including insulation and construction materials. The different types include: 1) Plain Foil Facing, which is a smooth, uncoated aluminum foil; 2) Coated Foil Facing, which has a protective coating applied to one or both sides; 3) Laminated Foil Facing, where aluminum foil is bonded to other materials like polyester or polyethylene; 4) Embossed Foil Facing, featuring a pattern or texture on the surface for added strength or aesthetic purposes; and 5) Reinforced Foil Facing, which incorporates additional materials to enhance durability and tear resistance.</p>

- Q: Is it safe to use aluminum foil facing inside a microwave oven?

- <p>No, it is not safe to use aluminum foil facing in the microwave oven. Aluminum foil can cause sparks and potentially start a fire due to the reflective nature of the metal. It can also damage the oven's interior. Always use microwave-safe materials and avoid metal when cooking in a microwave.</p>

Send your message to us

High Quality Closed Cell Flexible Rubber Plastic Foam with Aluminum Foil Facing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords