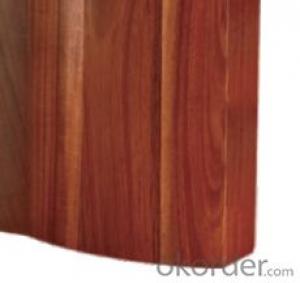

knife seat,F-KB011 acacia wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product name:acacia wood knife seat

material:acacia wood

N.W.:0.774kg

MEAS:14.5*10*10cm

Specifications:

Has the quite distinct shape of the mountain wood grain, and the contact surface is a good sense

Excellent toughness, process into various curved according to the needs , full of beauty

Solid texture,manufactured goods with firm structure,prolonged service life

The texture of rubber wood is fine and closely woven,pore full of lots ot padding so it's hard to absorb water and corrode.

Description:

1、The knife seat use material of high quality natural acacia wood and take professional advanced machine equipment and manual binding.

2、The knife seat was refined by material, assembly, polishing, painting and other procedures.

3、The knife holder has the advantages of real materials, excellent workmanship, mouldproof and moth proofing, anti bacteria, wear-resisting etc.

4、Hoteam commerce co.,LTD,is a manufactory specialized in all kinds of wood knife handles,wood seats,chopping boards and other woodworks.

5、Because the knife tool contact with tool wet food for long time, is very easy to breed bacteria, you should ensure that dry and clean and put it in the open air

acacia wood knife seat quantity:

Safety, health, bright color,durable,the everyday necessary good products

Anti-mildew change,anti moth

Environmental protection,no crack,no decay

Primary Competitive Advantages:

Brand-name Parts Country of Origin

Distributorships Offered Experienced Staff

Form A Green Product

Guarantee/Warranty International Approvals

Packaging Price

Product Features Product Performance

Prompt Delivery

- Q: How to install CNC machine tool

- Side frame installation(1) remove the strip, the pressure plate, cleaning the guide rail and other processing surface, check the defect and put on the lubricating oil.(2) the connecting piece of the tool holder and the counterweight, such as the bearing, the pulley (or the chain wheel), the axle, the hanging rope or the chain, and so on.(3) the stone school F on the positive exploration in wood, clean school guide surface, with lubricating oil, the side head hanging on it, slowly close to the school with positive guide, strip, plate, preliminary adjustment guide clearance, connection lifting mechanism.(4) connect the counterweight and the side of the turret, rose hand operation knife, check whether there is blocked, demolition of timbers.

- Q: How can we remove the NC turret

- This is not more than the ordinary lathe CNC lathe, if so simple to take out, it is difficult to achieve automatic change

- Q: CNC lathe tool holder four and six stations which good

- The internal structure of the turret principle is similar, but the four station looks like car carriage, six station is a brick tower structure, slightly larger, a fixture of processing content more, six station processing large size parts, the adjacent knife knife may interfere with the four station, six station four station your. Think about it.

- Q: In front of the turret with rear turret in the car to count the G41G42 cutter compensation when there is no difference?

- The turret of the numerical control lathe is the front knife holder in the operator's side.The common lathe is the rear cutter.When the tool head, the G42 tip radius compensation right bias in the car when the hole, when the car is round with G41.

- Q: What is a tray roll bag

- Industrial heat shrinkable tray with a roll bag weight is about 1 kg. A roll of 30 or soAt present, the thickness of the large 100um bag is mainly imported

- Q: Is the plastic knife holder of roller skate good or metal knife holder good?

- Metal turret. Should not be used to, we do not play a long time just go up the leg will be very tired. Shoes foot is tight, a little sluggish flow of feeling. Good fun.

- Q: 4 station tool structure is the best. The detailed process of mechanical transmission, their demolition a few times, the worm brake to lift the knife. There is a problem in the rise of the knife in the process of the top cap of the spring to the top of the iron cover dead, the result of the death of the knife holder, can not drive. I estimate that the top cap and the angle and the first bevel on the iron cover are not consistent due to wear and tear. For I a person's opinion, hope you enlighten me

- Automatic tool change when the rotation of the tool holder; manual for the knife can be changed in place when the knife number and the parameters of the same; that is, to determine the issue of the disk is not a problem, the position is also aligned; how to solve this problem. Waiting for your guidance.

- Q: The first reason is that the cutter shaft of the motor shaft is broken for a shaft / how long it will not be able to die!

- Open the cleaning to keep the knife holder into the garbage or not to check whether the motor is enough

- Q: CNC lathe hit the knife after the knife center height, how to deal with?

- Maybe the dowel pin is misplaced,tool change pin

- Q: What is the material of the cutting tool

- First say blade. Commonly used materials: 1 high speed steel (also known as Feng Steel, Bai Gang): is a kind of tungsten, chromium, vanadium, molybdenum and other high alloy tool steel more elements. 2: tungsten carbide hard alloy by high hardness and melting point, titanium carbide and cobalt cemented metal made by powder metallurgy method, the hardness and wear resistance are good, hot hardness is very high, so the cutting speed is higher than high speed steel several times or even several times, can cut material of high speed steel no processing method, but the bending strength and impact toughness of high speed steel much worse than. 3, ceramics: alumina powder sintered at high temperature and the ceramic blade, the hardness, wear resistance and heat resistance are higher than the cemented carbide.

Send your message to us

knife seat,F-KB011 acacia wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords