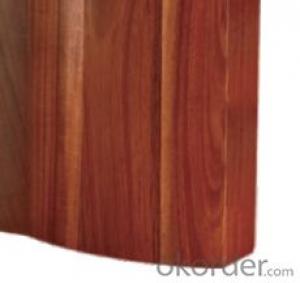

knife seat,F-KB013 acacia wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product name:acacia wood knife seat

material:acacia wood

N.W.:1.362kg

MEAS:22*18cm

Specifications:

Has the quite distinct shape of the mountain wood grain, and the contact surface is a good sense

Excellent toughness, process into various curved according to the needs , full of beauty

Solid texture,manufactured goods with firm structure,prolonged service life

The texture of rubber wood is fine and closely woven,pore full of lots ot padding so it's hard to absorb water and corrode.

Description:

1、The knife seat use material of high quality natural acacia wood and take professional advanced machine equipment and manual binding.

2、The knife seat was refined by material, assembly, polishing, painting and other procedures.

3、The knife holder has the advantages of real materials, excellent workmanship, mouldproof and moth proofing, anti bacteria, wear-resisting etc.

4、Hoteam commerce co.,LTD,is a manufactory specialized in all kinds of wood knife handles,wood seats,chopping boards and other woodworks.

5、Because the knife tool contact with tool wet food for long time, is very easy to breed bacteria, you should ensure that dry and clean and put it in the open air

acacia wood knife seat quantity:

Safety, health, bright color,durable,the everyday necessary good products

Anti-mildew change,anti moth

Environmental protection,no crack,no decay

- Q: What are the reasons for the deviation of the CNC lathe tool holder after each turn

- Do you mean that the deviation is not parallel to the axis of the spindle after the lock is locked, or if you have the same knife position

- Q: How to install CNC machine tool

- Vertical turret mounting(1) open the guide strip and press plate on the cutter holder, clean the guide rail and the processing surface, check the guide rail surface should be intact without rust.(2) the left and right vertical turret respectively with lifting beam, with oil on the rail surface, the gear transmission is to mobile tool beam assembly hole, mounted on the plate, strip, slide clearance adjustment.(3) the vertical shaft of the vertical cutter head is installed, and the compression member of the balance hammer is removed, so that the counterweight is balanced.

- Q: How to save the supermarket roll bag?

- In the place of the roll bag placed in the food and goods, dry and wet varieties, such as the separation of each line of the front of the sale of things, do not half-way and tail placed, mainly with the sale of goods placed matching

- Q: How to do the tool holder of the NC turret with too long time

- Open the lid of the tool holder to see whether the round pad is loose or abnormal

- Q: CNC lathe tool holder four and six stations which good

- Four station problem seems to be more than six station problem, from my factory 16 sets of 20, 30 numerical control, rigid and rotary accuracy of six stations, good use

- Q: CNC turret can be turned into 45 degrees ah? Can you turn counterclockwise?

- You mean it is not a simple numerical control of the car on the four bit, only in one direction, this may not be achieved, unless there is a problem. Eight knife position is the kind of post, you can, as well as 12 knives, each turn only about 30 degrees, you can choose the nearest, the direction of the two can be.

- Q: What is the tool rest

- Device for processing long shaft on horizontal lathe.

- Q: Lathe machining slender workpiece should be matched with the knife

- Choose reasonable tool angle; in order to reduce the radial cutting force, should choose the larger main angle; the front cutter surface should be grinded chipbreaker R=1.5-3mm, the chip flow surface to be machined; the tool surface roughness to be small, and keep a sharp cutting edge.

- Q: CNC machine tool can be drilled hole how to center

- 1, do not need to set the coordinate system (the center), is loaded with a knife, in the process of preparation of processing requirements, reasonable adjust the height and verticality, the proper use of speed and feed rate, the knife tool can be set, simple, can fix a hole.2, if the degree of difficulty and high requirements, please use the circular drilling instructions programming.

- Q: Why do you want to use the center frame and the tool holder when machining the slender shaft?

- In order to prevent the workpiece from bending deformation due to the radial cutting force, the central frame or the tool holder is used as the auxiliary support to increase the rigidity of the workpiece.

Send your message to us

knife seat,F-KB013 acacia wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords