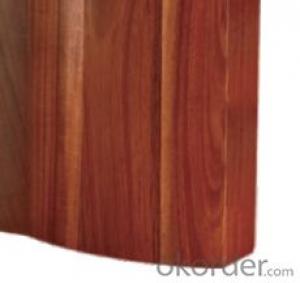

knife seat,F-KB012 acacia wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product name:acacia wood knife seat

material:acacia wood

N.W.:2.23kg

MEAS:28*19.5*17cm

Specifications:

Has the quite distinct shape of the mountain wood grain, and the contact surface is a good sense

Excellent toughness, process into various curved according to the needs , full of beauty

Solid texture,manufactured goods with firm structure,prolonged service life

The texture of rubber wood is fine and closely woven,pore full of lots ot padding so it's hard to absorb water and corrode.

acacia wood knife seat quantity:

Safety, health, bright color,durable,the everyday necessary good products

Anti-mildew change,anti moth

Environmental protection,no crack,no decay

Primary Competitive Advantages:

Brand-name Parts Country of Origin

Distributorships Offered Experienced Staff

Form A Green Product

Guarantee/Warranty International Approvals

Packaging Price

Product Features Product Performance

Prompt Delivery

- Q: After the work of the machine tool, the knife is not changed, the time is good and bad, the circuit is not a problem, mechanical rotation is normal. What are the specific reasons

- Check your phone when the good or bad adjustment should be able to keep the turret is not in place after the rotation of the signal to detect the location of the sensor block or the location of the adjustment of your Holzer like

- Q: To the signal line where the pull resistance, pull resistance to do with the trouble to say clearly?

- Our company's CNC lathe turret is done so that the high level to the low level of the input signal to adapt the system to understand it

- Q: How to install CNC machine tool

- Side frame installation(1) remove the strip, the pressure plate, cleaning the guide rail and other processing surface, check the defect and put on the lubricating oil.(2) the connecting piece of the tool holder and the counterweight, such as the bearing, the pulley (or the chain wheel), the axle, the hanging rope or the chain, and so on.(3) the stone school F on the positive exploration in wood, clean school guide surface, with lubricating oil, the side head hanging on it, slowly close to the school with positive guide, strip, plate, preliminary adjustment guide clearance, connection lifting mechanism.(4) connect the counterweight and the side of the turret, rose hand operation knife, check whether there is blocked, demolition of timbers.

- Q: How can we remove the NC turret

- The first part of the rotation, two screws in the middle of the release, and then lock the 12 release of the knife rest, remember there are still under the four, in the middle of the road there is a flexible adjustment of the long screws

- Q: How to maintain the lathe tool holder

- If the positioning and clamping action is normal, the push rod 11 is in contact with the corresponding contact 12, and the signal is sent to indicate that the tool changing process has ended, and the cutting process can be carried out.In addition to the positioning of the hydraulic cylinder and the positioning pin, the motor can also be used to drive the clutch to locate, as well as other indexing and positioning mechanisms.

- Q: These possibilities have been tested, or useless

- Spend some money, from bending machine manufacturers please a teacher to do.

- Q: What are the parts of the lathe and tool holder

- A lathe is a device; a tool holder is a lathe.

- Q: 1, CNC horizontal lathe tool holder with front and rear respectively. CNC vertical lathe tool holder how to classify?2, no matter front or rear CNC lathe, cutter movement from right to left (along the Z axis) with G42 compensation?

- 1: CNC vertical lathe no front and rear points, and it is different in general, the sleeper, knife in the right side of the center of the spindle, convenient use and debugging. The car generally have two knife, one is the vertical tool holder, but also often use the tool holder (according to different parts processing), can move up and down about (X, Z). One is the side of the knife, the general processing parts of the outer circle and the vertical knife can not be processed.2: personal understanding, CNC lathe general rarely used tool about compensation instruction, but to consider the nose arc, arc may result in the instruction of size and the size of the actual processing gap, but it can be in the compensation of tool interface, realize the compensation problem of the arc.

- Q: The direction of the tool head and the tool head of the NC lathe

- G41g42 use the judgment of the tool tip is not the same as you this figure to 09 knife point for the center of the rotation of 180 degrees is the rear tool head position input value evaluation standard front and rear is the same as the input value

- Q: What is the reason why the turret of NC lathe is not maintained?

- First, the bad disk, this may not be great.Two, the inside of the positioning pin broken.Three, the hollow shaft fracture.

Send your message to us

knife seat,F-KB012 acacia wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords