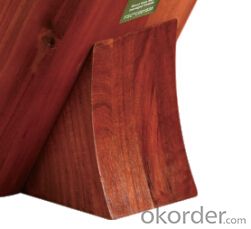

knife seat,F-KB005 acacia wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product name:acacia wood knife seat

material:acacia wood

N.W.:1.222kg

MEAS:23*18*13cm

Specifications:

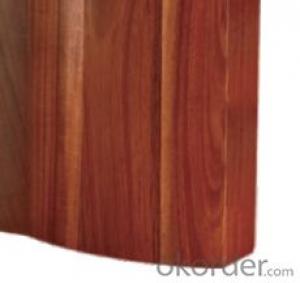

Has the quite distinct shape of the mountain wood grain, and the contact surface is a good sense

Excellent toughness, process into various curved according to the needs , full of beauty

Solid texture,manufactured goods with firm structure,prolonged service life

The texture of rubber wood is fine and closely woven,pore full of lots ot padding so it's hard to absorb water and corrode.

Description:

1、The knife seat use material of high quality natural acacia wood and take professional advanced machine equipment and manual binding.

2、The knife seat was refined by material, assembly, polishing, painting and other procedures.

3、The knife holder has the advantages of real materials, excellent workmanship, mouldproof and moth proofing, anti bacteria, wear-resisting etc.

4、Hoteam commerce co.,LTD,is a manufactory specialized in all kinds of wood knife handles,wood seats,chopping boards and other woodworks.

5、Because the knife tool contact with tool wet food for long time, is very easy to breed bacteria, you should ensure that dry and clean and put it in the open air

acacia wood knife seat quantity:

Safety, health, bright color,durable,the everyday necessary good products

Anti-mildew change,anti moth

Environmental protection,no crack,no decay

Primary Competitive Advantages:

Brand-name Parts Country of Origin

Distributorships Offered Experienced Staff

Form A Green Product

Guarantee/Warranty International Approvals

Packaging Price

Product Features Product Performance

Prompt Delivery

- Q: After the work of the machine tool, the knife is not changed, the time is good and bad, the circuit is not a problem, mechanical rotation is normal. What are the specific reasons

- Processing part of the program in the preparation of T code, the need to change the target knife number, the principle is to achieve this. The current knife number in the system inside, find the target knife number, according to the shortcut to the principle of selection, to determine the positive and negative. And calculate the number of knives that need to be turned over to the counter. In normal operation, the knife counting switch is used to subtract. The difference between the number of targets to subtraction, a reduction of 0, the completion of the signal, the library to stop running. The reason for this failure may be caused by the loose count switch and the error count. Control PLC counter in the middle, to see whether one correspondence can determine where the problem!

- Q: The system is a wide number of 980TDb, lathe is the Yunnan machine tool factory. Whether it is a manual tool change or MDI way to enter the specified number of knives, the tool holder always turn around, until the emergence of PLC alarm 1000 change knife time is too long, A0000.0 knife can not reach the designated position. What the problem ah, I did not move the parameters of the machine, ah, this morning is good, work in the afternoon a boot on this.Back to the origin of the machine are abnormal, and can not return to the origin of the machine. Press the corresponding button after the machine does not respond, will not act. It's normal in the morning.

- The tool holder decoder is abnormal, the maintenance personnel should be required to adjust the hardware equipment, and then modify the solution

- Q: To the signal line where the pull resistance, pull resistance to do with the trouble to say clearly?

- In a word: your signal circuit IC no internal resistance, protection. Pull the signal is determined by a high resistance resistor at the high level, while the resistance from the current limit, pull the same. Pull on the device is the injection current, the output current is down; just pull the weak and strong resistance, no strict distinction between what; for non (collector or drain) open circuit output circuit (such as gates) current and voltage capacity improvement is limited, the pull-up resistor is the main function of open circuit output type of circuit output current for the collector channel. All the pull-down resistor pull-up resistor is used in logic circuit, the circuit current is very small, the logic circuit of MOS tube bias current is microampere, even pA uA, the current level to provide a desired level, such as the current level without any output, because there is a pullup resistor so after a level is actually connected to a high level. Power amplifier circuit with no pull down resistor. Pull the signal is determined by a high resistance resistor at the high level, while the resistance from the current limit, pull the same. The pull-up resistor is the main function of the open circuit output current output channel for the collector; main function is connected with the pull-down resistor resistor together to line in the closed circuit driver (node) to a fixed level. Pull on the device is the injection current, the output current is down to note is that the pull-up resistance caused by too large delay output level, including the choice of the principle of resistance: 1, from the current irrigation ability to save the power consumption and chip considerations should be large enough; resistance...

- Q: How to install CNC machine tool

- Vertical turret mounting(1) open the guide strip and press plate on the cutter holder, clean the guide rail and the processing surface, check the guide rail surface should be intact without rust.(2) the left and right vertical turret respectively with lifting beam, with oil on the rail surface, the gear transmission is to mobile tool beam assembly hole, mounted on the plate, strip, slide clearance adjustment.(3) the vertical shaft of the vertical cutter head is installed, and the compression member of the balance hammer is removed, so that the counterweight is balanced.

- Q: How to distinguish the CNC lathe turret and turret turret after that car, belonging to the front tool or tool? Before the turret is cylindrical with G42 or inner circle?

- Whether NC or normal car, a knife in the side is the pre processor, or post, either rear or front, when processing with radius compensation are determined according to the post, the outer circle with G42, G41 in the hole.

- Q: How can we remove the NC turret

- First remove the inside, then the following,Two screws inside, then the eye, should use a punch, turn down

- Q: CNC lathe tool holder four and six stations which good

- Four station problem seems to be more than six station problem, from my factory 16 sets of 20, 30 numerical control, rigid and rotary accuracy of six stations, good use

- Q: The development trend of numerical control tool holder

- Vertical tool holder has four, six stations in the form of two, mainly for simple CNC lathe; horizontal tool holder has a position of eight, ten, twelve, can be positive and opposite direction rotation, the nearest election knife for the full function CNC lathe. In addition, the horizontal tool holder is provided with a hydraulic tool holder and a servo driving tool holder.

- Q: However, No. 2, No. 3, the normal use of potential energy on the knife No. 4 can not be normal use of the rotation has not stopped on the 1.

- Holzer component position (open the top cover can be seen as commonly referred to as the disk) is not right or damaged. Has not been able to stop because of the knife can not find the signal in place 4.

- Q: What is the function of the tool on the turret of NC lathe?

- The angle of the adjusting tool post is only temporary change, and the position of the tool post can be repeatedly positioned after the rotation of the tool holder!

Send your message to us

knife seat,F-KB005 acacia wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords