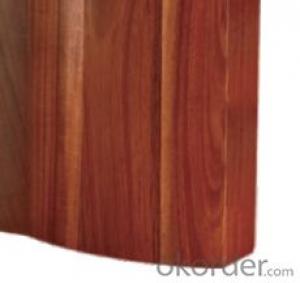

knife seat,F-KB010 acacia wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product name:acacia wood knife seat

material:acacia wood

N.W.:1.204kg

MEAS:23*19.5*6cm

Specifications:

Has the quite distinct shape of the mountain wood grain, and the contact surface is a good sense

Excellent toughness, process into various curved according to the needs , full of beauty

Solid texture,manufactured goods with firm structure,prolonged service life

The texture of rubber wood is fine and closely woven,pore full of lots ot padding so it's hard to absorb water and corrode.

Description:

1、The knife seat use material of high quality natural acacia wood and take professional advanced machine equipment and manual binding.

2、The knife seat was refined by material, assembly, polishing, painting and other procedures.

3、The knife holder has the advantages of real materials, excellent workmanship, mouldproof and moth proofing, anti bacteria, wear-resisting etc.

4、Hoteam commerce co.,LTD,is a manufactory specialized in all kinds of wood knife handles,wood seats,chopping boards and other woodworks.

5、Because the knife tool contact with tool wet food for long time, is very easy to breed bacteria, you should ensure that dry and clean and put it in the open air

acacia wood knife seat quantity:

Safety, health, bright color,durable,the everyday necessary good products

Anti-mildew change,anti moth

Environmental protection,no crack,no decay

- Q: After the work of the machine tool, the knife is not changed, the time is good and bad, the circuit is not a problem, mechanical rotation is normal. What are the specific reasons

- Processing part of the program in the preparation of T code, the need to change the target knife number, the principle is to achieve this. The current knife number in the system inside, find the target knife number, according to the shortcut to the principle of selection, to determine the positive and negative. And calculate the number of knives that need to be turned over to the counter. In normal operation, the knife counting switch is used to subtract. The difference between the number of targets to subtraction, a reduction of 0, the completion of the signal, the library to stop running. The reason for this failure may be caused by the loose count switch and the error count. Control PLC counter in the middle, to see whether one correspondence can determine where the problem!

- Q: The cutting surface of the optical fiber cutter is like this, what's going on?

- Adjustable knife before, to ensure that the four fiber laminated pad is clean, no deformation, shaft bearing is normal; then the first turn, all faces turn over, go a little bit higher tone. If you do not know the chaos, the first transfer can not be cut, and then slowly to a little bit up. The key is to check the fiber laminated pad and tool, or how to adjust is in vain. In addition, the quality of the blade is also related to some of the poor quality of the blade is lower than the hardness of silicon dioxide, it is difficult to cut, how to tune useless.

- Q: How to maintain the lathe tool holder

- Open the check, the ordinary lathe turret with old and new, open to find the damage in, say, the old pine lock off directly to lift the knife can be removed, the demolition of a new week is generally anti remember screw wire, remove the cover, which can disassemble parts, slowly observe there is a problem, most are rust, dirt and ash layer thickness will not cause, no live, no obvious wear and tear after cleaning equipment on the lookout to adopt good.

- Q: The development trend of numerical control tool holder

- The development trend of numerical control tool holder is: with the development of CNC lathe, CNC turret began to develop rapidly in the direction of tool change, electro hydraulic drive and servo drive. At present, the domestic CNC turret to electric, divided into two types of vertical and horizontal.

- Q: What is the difference between the NC lathe and the tool post

- Also, the most important thing is to look at the direction of the knife, there are positive and reverse difference, that is, M3 and M4

- Q: Tool holder S solution

- Vertical typeThe wheel frame, in fact, is a parallel steel frame structure.Than S, there are many advantages.For example, solid, DIY, modification, etc.

- Q: What is the difference between numerical control tool holder and power tool holder

- Seems to be a thing. The knife of CNC machine tool CNC turret should refers to the (for the realization of automatic tool change in the process), can be divided knife straight row knife, disc knife, knife and other bamboo hat.

- Q: CNC turret is also called the sender sensor

- It can be said that the signal is used to change the knife

- Q: The direction of the tool head and the tool head of the NC lathe

- G41g42 use the judgment of the tool tip is not the same as you this figure to 09 knife point for the center of the rotation of 180 degrees is the rear tool head position input value evaluation standard front and rear is the same as the input value

- Q: How to return to the ordinary lathe tool

- This problem is due to the positioning of the positioning pin hole under the knife body broken and small pallet wear caused by knife positioning, it must be replaced to accurate positioning pin and a positioning sleeve.

Send your message to us

knife seat,F-KB010 acacia wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords