KLB20-600 Bored Pile Drilling Rig for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

KLB20-600 Bored Pile Drilling Rig for Sale

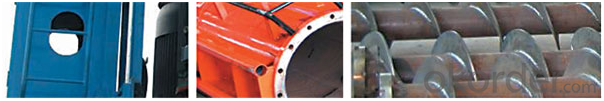

Product Features:

A Wide Choice Of Product: |

>>Our company is capable to manufacture various types of KL series drilling rigs. The max drilling depth could reach 20m to 34m.A wild range of products could be chosen for your practical needs. |

|

The column of the piling frame has two types, square and round. The former type applies back lift method. It is easily installed, safe and stable. The later type applies front lift method, the support rod will adjust itself when lifting the column. The column is higher, the drilling depth will go deeper. |

|

Higher Efficiency And Lower Consumption: |

>>The hydraulic system uses constant power variable design with low loss.The large flow, low failure rate, and high efficiency piston pump ensures the hydraulic components working well. |

|

high Reliability And Flexibility: |

>>The rotation system works with hydraulic flow. The rotating speed could be controlled to avoid impact. The failure rate is much reduced. The assistant hoist also uses hydraulic winch so the winding speed can be controlled at the operator’s will. Such design provides much convenience in the working process. |

|

Convenience In Dismantling, Transportation And Maintenance: |

>>With many years improvement and seeking for perfection, each part of the machine has well considered its convenience in dismantling, transportation and maintenance. The height and width of the largest part is designed within the range of transportatio lmits. |

|

Humanized Design: |

>>Much effort has been taken to increase the technical content on our products as well as humanized design. The machine is integrated with mechanical, electrical, hydraulic, and electronic devices. The appearance of the machine body, the comfort of the operator, the agility of the movements and so on are all well considered when designing the machine.Remote-control handle is optional due to the client's needs. |

|

Unique Design: |

>>After many years of experience in manufacturing the machine and analyzing feedbacks from our loyal clients, we made unique improvements in the easy-malfunction parts on the drilling rig: The bottom pillar of the column uses universal joint to enable the pole adjusted from left-right and front-back directions. The side support adjustment mechanism uses hydraulic motor instead of electrical motor which may affect the adjustment stroke or worm and gear which may shorten the life period. The supporting leg cylinder base uses large round box structure to avoid distortion at the working process. |

|

Multi-function: |

>>KL series is our new generation multi- function piling frame: with different power plant it can not only be used to do bored pile drilling or construct continuous wall by SMW method, but also do diesel hammer or hydraulic hammer pile driving. |

|

| KLB20-600 | ||

|---|---|---|

| Move method | Electro-hydraulic step | |

| Max drilling depth | 20m | |

| Max drilling diameter | φ600 | |

| Max output torque | 36KN· | |

| Rod rotated speed | 26r/mi | |

| Allowed lifting force | 240KN | |

| Power for power head | 45KWX2 | |

| Reductor of power head | ZZSH430 | |

| Leader size | Rectangle section | |

| Leader height | 24m | |

| Leader oriented center distance | 600Xφ102 | |

| Leader incline range | 5°front inclination 3°back inclination | |

| Stroke | 1.05m | |

| Climbing ability | <6° | |

| Rotary | Rotary way | Rotary motor |

| Rotary angle | ≤360° | |

| Rotary speed | 0~0.3 | |

| Main winch | Single pulling force | 4T |

| Increasing speed | 2.4/3.0/3.5 | |

| Motor power | 15KW | |

| Assist winch | Single pulling force | 1.5T |

| Increasing speed | 20m/min | |

| Motor power | 7.5KW | |

| Overall dimension(L*W) | 9m×4.5m | |

| Total weight(T) | 52T | |

FAQ

1.Which payment terms can we accept?

Normally we can work on T/T term or L/C.If you choose T/T,30% payment is required in advance and 70% balance shall be settled before shipment often,it rang a little.

2.How long will our price be valid?

We are friendly dealer, never greedy windfall profit, our price remains stable,except the exchange rate and the increasing labor cost and material cost.

3.What are our advantages compared with manufacturers?

a.Detailed training-We can provide training services to different users. The training sessions include product training,operating training, maintenance know-how,standard and so on to fulfill your individual needs.The training can be conducted at client’s site.

b.Available after service-With our global distributor network, you are guaranteed with fast deliveries and services if you submit your requests.

- Q: What is an impact pile driver?

- You mean the kind of pile driver that used to use high explosive diesel engines to produce impact?The principle is like using the percussion hammer nails, using a hammer impact in the nail head will generate the nail.It's very seldom used now.

- Q: say no money, the machine is more expensive, but still busy every day do not win, do not know is true or false?

- Certainly money ah, now people are selfish, just want to make money, Matlock machine good, I also encountered such a thing.

- Q: Working principle of pile driver

- The pile hammer is attached to two parallel vertical guide rods (commonly called Longmen) at the front of the pile support and hoisted with lifting hooks. Pile frame is a steel tower, in the back part is provided with a winch for hoisting pile and the pile hammer, pile in front of the guide frame of two guide rods, used to control the direction of the pile, pile according to the design range accurately penetration formation. The tower and the guide frame can be used to batter pile deflection.

- Q: I have been using a common type of 260 fence pile driver, I still feel good with the use of, I heard that the loading barrier, pile driver more cattle I'd like to ask if the loader guardrail is practical? What is the daily piling efficiency? What's the fuel consumption? Please let me know when I've got the trouble. I'll try to buy one if I know the right thing.

- And, as I have seen, ha, five loaders have been used for more than a year since the purchase. There has been no major failure. It may be luck. Arguably, domestic engineering equipment should not be so used.I suggest, if you small quantities or steadfastly practical cost 260, the large quantity you can choose the loading type guardrail piling machine try very energeti.

- Q: I have two pile drivers, followed by engineering piling, what qualifications do you need?

- Engage in the construction site of the pile foundation need enterprise qualification, suggest you go to affiliated company

- Q: Bridge pile driver is a stone below, how to do?

- What's your machine, please? If your machine is an impact drill, I suggest you use the hollow hammer. The ventilation is fast, the cross drill is easy to break, the side is slow, and several drilling rigs have their respective numbers. Next time they are talking to you

- Q: AMD FX 8350 eight core CPU AM3+ piling machine and tin box what is the difference between the master pointing

- All one to。 Most of the cartons were in 2013. But in 2012, they were all iron boxes. And the radiator of the paper box doesn't have the radiator of the iron box. Although the AMD platform U original box radiator is no use. But I always feel sick. Bought on Jingdong.

- Q: How many meters per day can a foundation shovel in Luoyang be 80 centimeters in diameter? Is it easy to damage?

- About 8 meters per hour, durable, bad, are spare parts, such as wire rope, brake, triangle belt, but do more work, it will earn!

- Q: Buying a pile driver doesn't know how to make a profit Has anyone done that yet?

- Because, after all, the pile driver is not only a few years, the choice of good quality in the early may not be cost-effective, but after taking into account, or suggest that you buy a little bit of the machine. After all, if the driver problem that you every two or three days, the work is not good for.

- Q: The principle of pile driver

- (3) vibration hammer. Using the mechanical vibration force of the pile hammer to make the pile sink into the ground, it is suitable for carrying less precast concrete pile, steel sheet pile and so on.(4) static pile pressing machine. Produced by mechanical hoist or the pressure of the hydraulic system, the pile in the hydrostatic pressure under the action of pressure in the soil, various types of precast pile used in general bearing capacity.

Send your message to us

KLB20-600 Bored Pile Drilling Rig for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords