KLU20-600 Bored Pile Drilling Rig for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

KLU20-600 Bored Pile Drilling Rig for Sale

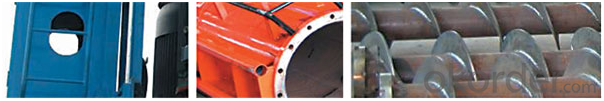

Product Features:

A Wide Choice Of Product: |

>>Our company is capable to manufacture various types of KL series drilling rigs. The max drilling depth could reach 20m to 34m.A wild range of products could be chosen for your practical needs. |

|

The column of the piling frame has two types, square and round. The former type applies back lift method. It is easily installed, safe and stable. The later type applies front lift method, the support rod will adjust itself when lifting the column. The column is higher, the drilling depth will go deeper. |

|

Higher Efficiency And Lower Consumption: |

>>The hydraulic system uses constant power variable design with low loss.The large flow, low failure rate, and high efficiency piston pump ensures the hydraulic components working well. |

|

high Reliability And Flexibility: |

>>The rotation system works with hydraulic flow. The rotating speed could be controlled to avoid impact. The failure rate is much reduced. The assistant hoist also uses hydraulic winch so the winding speed can be controlled at the operator’s will. Such design provides much convenience in the working process. |

|

Convenience In Dismantling, Transportation And Maintenance: |

>>With many years improvement and seeking for perfection, each part of the machine has well considered its convenience in dismantling, transportation and maintenance. The height and width of the largest part is designed within the range of transportatio lmits. |

|

Humanized Design: |

>>Much effort has been taken to increase the technical content on our products as well as humanized design. The machine is integrated with mechanical, electrical, hydraulic, and electronic devices. The appearance of the machine body, the comfort of the operator, the agility of the movements and so on are all well considered when designing the machine.Remote-control handle is optional due to the client's needs. |

|

Unique Design: |

>>After many years of experience in manufacturing the machine and analyzing feedbacks from our loyal clients, we made unique improvements in the easy-malfunction parts on the drilling rig: The bottom pillar of the column uses universal joint to enable the pole adjusted from left-right and front-back directions. The side support adjustment mechanism uses hydraulic motor instead of electrical motor which may affect the adjustment stroke or worm and gear which may shorten the life period. The supporting leg cylinder base uses large round box structure to avoid distortion at the working process. |

|

Multi-function: |

>>KL series is our new generation multi- function piling frame: with different power plant it can not only be used to do bored pile drilling or construct continuous wall by SMW method, but also do diesel hammer or hydraulic hammer pile driving. |

|

| KLU20-600 | ||

|---|---|---|

| Move method | Electro-hydraulic step | |

| Max drilling depth | 20m | |

| Max drilling diameter | φ600 | |

| Max output torque | 36KN·m | |

| Rod rotated speed | 26r/min | |

| Allowed lifting force | 240KN | |

| Power for power head | 45KWX2 | |

| Reductor of power head | ZZSH430 | |

| Leader size | Rectangle section | |

| Leader height | 24m | |

| Leader oriented center distance | 600Xφ102 | |

| Leader incline range | 5°front inclination 3°back inclination | |

| Length of crawler on the groud | 3.2m | |

| Width of track plate | 600mm | |

| Climbing ability | <4°< span=""> | |

| Rotary | Rotary way | Rotary motor |

| Rotary angle | ≤360° | |

| Rotary speed | 0~0.3 | |

| Main winch | Single pulling force | 4T |

| Increasing speed | 2.4/3.0/3.5 | |

| Motor power | 15KW | |

| Assist winch | Single pulling force | 1.5T |

| Increasing speed | 20m/min | |

| Motor power | 7.5KW | |

| Overall dimension(L*W) | 9m×4.5m | |

| Total weight(T) | 52T | |

FAQ:

1,Are you trading company or manufacturer?We are professional manufacturer, and our factory mainly produce water well drilling rig, core drilling rig, DTH drilling rig, piling rig, etc. Our products have been exported to more than 50 countries of Asia, South America, Africa, and get a good reputation in the world.

2,Are your products qualified?Yes, our products all have gained ISO certificate,and we have specialized quality inspection department for checking every machine before leaving our factory.

3,How about your machine quality? All of our machines hold the ISO, QC and TUV certificate, and each set of machine must pass a great number of strict testing in order to offer the best quality to our customers.

4,Do you have after service?Yes, we have special service team which will offer you professional guidance. If you need, we can send our engineer to your worksite and provid the training for your staff.

5,What about the qaulity warranty?

We offer one-year quality warranty for machines' main body.

6,How long can you deliver the machine?

Generally, we can deliver the machine in 7 days.

AFTER SALES:

1.New machine provides technical train.

2.Once anything goes wrong with the machine by normal using,our technical person must appear at the first time no matter where you are.

3.When the machine should be maintained,you will receive the reminding from us.

4.According to different geological conditions,we will recommend different construction plans for you.

5.Remind you which are wearing parts,so you can prepare enough.

6.24 hours respond to your quality problem.

7. Other customer's reasonable request

1.Reply your inquiry in 24 working hours.

2.Experienced staffs answer all your questions in professional and fluent English.

3.Customized design is available. OEM is welcome.

4.Exclusive and unique solution can be provided to our customer by well-trained and professional engineers and staffs.

5.Special discount and protection of sales area provided to your distributor.

6.Do the best reliable heavy-duty single drum vibratory road roller in China.

7.Warranty period is 1-year or 1500 working hours against Bill of Lading.

ion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises!

CNBM International works as the international platform for CNBM Group. In 2013, our total sales income was more than US$16.8 billion dollars.Every year we import large quantity of iron ore, coking coal and thermal coal etc from India, Brazil, Australia and Russia and other countries.ld'>Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

- Q: Like bored pile machines and precast pile machines, they have no wheels, and they are very bulky. How do they move?Some people say that the demolition and then installed, a construction site three hundred or four hundred piles, it is difficult to dismantle three hundred or four hundred times?

- What is the construction of a rotary boring pile driver in the building?:1, the use of mud pump, drilling the soil out, forming a pile hole, and then steel cage, pouring concrete.2. Pile driver consists of pile hammer, pile foundation and auxiliary equipment. The pile hammer is attached to two parallel vertical guide rods (commonly called Longmen) at the front of the pile support and hoisted with lifting hooks. The pile foundation is a steel structure tower with a windlass at the back of which is used to lift the pile and hammer. A guide frame consisting of two guide rods is used in front of the pile to control the direction of the pile driving so that the pile can be accurately penetrated into the formation in accordance with the design orientation. The basic technical parameters of a pile driver are impact weight, impact kinetic energy and impact frequency. According to the motion of the pile hammer power source can be divided into hammer, hammer, diesel hammer, hydraulic hammer etc..

- Q: What is an impact pile driver?

- You mean the kind of pile driver that used to use high explosive diesel engines to produce impact?The principle is like using the percussion hammer nails, using a hammer impact in the nail head will generate the nail.It's very seldom used now.

- Q: Pile foundation

- Sinking pile foundation pile, cast-in-place pile is the reinforced concrete or steel pipe pile tip with valve pile tip at the bottom of the sleeve, sinking to the required depth by hammering or vibration, the tube placed inside the reinforcement cage, concrete pouring, pull out pipe forming. Bored pile foundation construction - long spiral drilling bored pile construction, the main processes are: site preparation, the laying of protective cylinders, preparation of mud, drilling, cleaning, reinforcement cage, into the hole and pouring underwater concrete. The key is drilling, the main methods are: rotating method, impact method and punching method. The rotary drilling can be divided into positive revolving drilling, reverse circulation rotary drilling, long spiral drilling machine and so on. Bored pile foundation construction - reverse and reverse rotating drilling, positive rotation drilling: mud from the mud pump at high pressure from the mud tank into the bore of the drill pipe, the drill hole through the mouth of the injection.

- Q: Code for installation and operation of pile drivers

- 4. Check whether the voltage of the power supply meets the requirements.5, according to the daily maintenance project to each department lubrication, maintenance.Five, pile driver in the work safety precautions:1, when the piling machine work, there should be special command. The conductor and operator should check each other's signals before they work. Work closely together.2, at the start of the bell signal or other applications, notify the staff around to leave.3, hammer and pile cap, pile cap and column (or pile) plane to pad, a connecting bolt should be tightened, and should always check whether there is loose.4. The starting of the pile driver should be adjusted from low gear to high speed.5, the pile driver in the work should be closely observed on the control panel current, voltage instructions. If abnormal sound or other abnormal conditions are found, stop inspection immediately.6, always check the temperature of the bearing and the bearing cover screws is loosening, should strictly examine the eccentric block coupling screw loosening, prevent the occurrence of accidents.7, sink, column (or pile) prohibited to stand around.8, piling machine with water, mud suction sink, should contact in advance with the relevant personnel, and take care of each other at work.9, long pipe column or pile and the installation of pile cap, the staff must wear safety belts.10 、 in the process of sinking, it is strictly prohibited to do mechanical maintenance work.Six after the stop of the piling machine, the power shall be cut off immediately, and the pile driver and motor shall be inspected and maintained.Seven, piling machine long-term disabled, should be kept in storage, the motor should be good moisture-proof protection, the control panel of the instrument, should be removed, storage, storage.

- Q: Highway guardrail, piling machine, drilling, piling price

- Look at what the ground looks like, 0635-5454-588

- Q: What about a dry digger, a pile driver? How much money? What's the speed?

- Shanghai Zhonglian second-hand excavator market professional solution for you:1, the dry piling machine can be refitted by excavator, but in fact it is very convenient.

- Q: What are the prospects for a small pile driver and a foundation pile driver? Will it make money?

- Small rotary drilling rig prospect is very good, is generally 40 meters below the depth of drilling rig is defined as a small rotary,

- Q: Do you have a teacher with you?. I am 32 years old this year. I really want to learn this kind of machine

- Excavator forklift forklift, good work

- Q: How much is the average cost of piling a metre?.Construction Engineering piling machine how much money? (can be more than 30) piling generally hit a meter, what is the cost?. How much can I pay for a metre? What's the procedure for piling operators?

- Domestic about 2000000, the best to count Germany and Italy one, at least 500 - about 6000000! About one meter. Need fifty or so, a twenty meters stake will not exceed one thousand dollars, the operation of pile machine need pile machine driver's license, also can hang some of the company's account.

- Q: How many types of piles are there in the site? What procedures are usually used for piling? Such as eyes open what kind of..

- (3) screw in pile;The screw in pile is a spiral plate at the end of the pile, which is gradually transferred into the foundation by the torsion of the external machinery. The cross section of the pile is generally small, but the spiral plate is relatively large, and the disturbance of the pile side soil is larger during the construction of the spiral pile, so the screw plate of the pile head bears the axial pressure or tensile force of the pile.(4) vibration sinking pile;The vibration sinking pile is the vibrating sinking pile, and the precast pile is sunk into the ground by the vibration and vibration action of the vibrating pile driving machine. This method of construction is basically between the method of penetration and the method of pressing in.

Send your message to us

KLU20-600 Bored Pile Drilling Rig for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords