Kirkland Aluminum Foil Sheets - Mill Finished Continuous Casting Aluminum Sheet AA1050

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

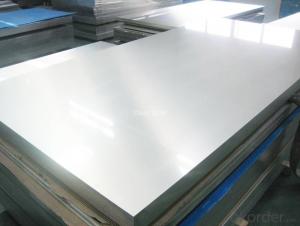

1.Structure of Product Description

Mill Finished Continuous Casting is one semi-finished aluminium material.Aluminium is the most common metal in the world. For the alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of stee.Moverover, the aluminium material can be anti-rust, compared to steel material. That's why many customers prefer aluminium products.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image:

4.Products Specification

| Alloy | Thickness | Coil ID | Coil Weight | Coil Core |

| AA1050 | 0.2mm-3mm | 508mm+/-10mm | 2-2.5 tons | Paper Core |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: I am doing a report on machining aluminum and characteristics of aluminum and can not find what the 6061 stock stands for. Looked all over library, internet, etc.

- The spec for 6061 aluminium, can be found on this link - 66.102.9.104/search?q=cache:ALU5S...

- Q: Can aluminum sheets be used for insulation cladding?

- Yes, aluminum sheets can be used for insulation cladding. Aluminum is a lightweight and durable material that has excellent thermal conductivity properties. It can effectively reflect heat and prevent the transfer of thermal energy, making it an ideal choice for insulation cladding. Additionally, aluminum sheets are resistant to corrosion, moisture, and fire, further enhancing their suitability for insulation applications. Overall, using aluminum sheets for insulation cladding can help improve energy efficiency, reduce heat loss, and enhance the overall performance of a building or structure.

- Q: This question asks for methods to guarantee that the edges of installed aluminum sheets remain straight and smooth.

- <p>To ensure that the edges of aluminum sheets are straight and smooth after installation, follow these steps: 1. Use high-quality aluminum sheets that are free from warping or defects. 2. Measure and cut the sheets accurately to avoid any discrepancies. 3. Use a sharp, clean cutting tool to prevent jagged edges. 4. Smooth out any rough edges with a file or sandpaper. 5. Install the sheets with precision, ensuring they are aligned properly. 6. Use appropriate fasteners and brackets to secure the sheets without causing any distortion. 7. Regularly inspect and maintain the sheets to address any issues promptly. By following these steps, you can maintain the straightness and smoothness of aluminum sheet edges after installation.</p>

- Q: Can the export quality of China's aluminum plate meet the requirement of ASTM B 209? Is this requirement for our country? Master the exhibitions, O (a _ U) O thank you

- ASTM is the standard used in the United StatesEquivalent to China's GBGenerally equivalent to the use of Chinese standardsSpecific depends on whether the customer agreesIn fact, just do a testMeet its requirements

- Q: I may use the copper or brass for an inlay on a decorative piece of aluminum I'm working on.....

- aluminum okorder / so what you are finding is that aluminum will melt before the copper or brass...

- Q: What is the electrical conductivity of 101 aluminum sheets?

- The electrical conductivity of 101 aluminum sheets is high due to aluminum being a good conductor of electricity.

- Q: How are the aluminum plates cut?

- A little thick with shears or plasma cutting machine, cutting machine words cut out if more smooth, no burr, but the pattern is simple, can be arbitrary cutting plasma cutting machine, but cutting burrs, rough.

- Q: I would like to use an alloy of copper often called aluminum bronze or aluminum brass for making wire wrapped jewelry but I am unable to find a supplier. An alloy that has no zinc or lead would be best to avoid toxicity problems. This alloy should be principally copper and aluminum but other added materials would be acceptable if not toxic. Nickel, silicon, manganese, and iron are sometimes added to increase performance of the alloy and should be acceptable (no lead or zinc please). The material obviously needs to be bendable enough to work with wire wrapping so if it is brittle it will not work. It should then be at least as usable as aluminum, copper, or stainless steel wire.

- My lady I nonetheless use it to cook dinner my hams and turkeys and to store meals in the frig, however its fitting a dinosaur and its on its last leg and there may be so many different matters now we can use but up to now years it had its use but science and Tech. Has come and made it out of date. However still I like to apply it to ocassions

- Q: Can aluminum sheet be used for aircraft skin panels?

- Certainly, aircraft skin panels can indeed be made from aluminum sheet. As a matter of fact, aluminum is extensively employed as the preferred material for constructing such panels owing to its highly advantageous properties. Aluminum possesses the qualities of being lightweight, robust, and resistant to corrosion, rendering it an ideal selection for aircraft production. Moreover, aluminum is effortlessly malleable, facilitating the shaping of the panels into the precise contours and curves necessary for aircraft design. Furthermore, it exhibits commendable heat conductivity, aiding in the dissipation of heat generated during flight. All in all, aluminum sheet is an exceptionally reliable and efficient material for the fabrication of aircraft skin panels.

- Q: What is the typical creep resistance of aluminum sheets?

- The typical creep resistance of aluminum sheets varies depending on the specific alloy and temper. Aluminum alloys typically have good creep resistance compared to other metals, especially at lower temperatures. However, the creep resistance of aluminum decreases significantly at higher temperatures. Aluminum sheets with higher alloying elements like copper, magnesium, or zinc tend to have better creep resistance than pure aluminum. Additionally, heat treatment processes such as cold rolling, annealing, or precipitation hardening can enhance the creep resistance of aluminum sheets. In general, aluminum sheets are known for their relatively low creep rates, making them suitable for various applications that require good dimensional stability over extended periods. However, it is important to note that the exact creep resistance of aluminum sheets can vary depending on the specific composition, processing, and operating conditions. Therefore, it is advisable to consult material specifications or conduct specific tests to determine the creep resistance of a particular aluminum sheet.

Send your message to us

Kirkland Aluminum Foil Sheets - Mill Finished Continuous Casting Aluminum Sheet AA1050

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords