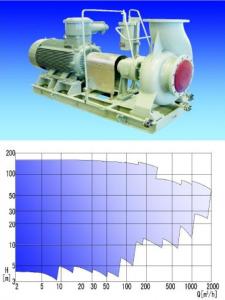

KCZ series standard chemical process pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product overview

KCZ standard chemical process pump is based on the absorption of similar products at home and abroad advanced technology, development and design in accordance with the international standard of international standard chemical process pump. KCZ standard chemical process pump structure was optimized by using CAD modular design, novel structure, reliable and good parts interchangeability, advanced hydraulic model, high efficiency, good cavitation, can satisfy the requirements of performance parameters under various working conditions.

Application field

Can be widely used in chemical, petroleum, metallurgy, power station, food, sugar, pharmaceutical, paper, synthetic fiber, water supply, seawater desalination, environmental protection engineering, heating and air conditioning and other fields.

Product features

1, KCZ standard chemical process pump technical conditions in accordance with ISO standards, safety and reliability of the operation of the pump, versatility, applicability is wide and enforcement of the structure of industrial process pump at the same time, after the pull type design, safe and convenient pump disassembling maintenance;

2, adopt CAD modular structure design, component assembly, with series products between parts with maximum interchangeability;

3, adopts the integral casting closed impeller, strong adaptability to the operating conditions, with high efficiency and cavitation performance of the optimal, with a standard back impeller impeller or balance hole, can reduce the axial thrust and seal chamber pressure, prolong the service life of sealing and bearing.

4, the center line of the pump body at the top of the export and pump foot support, has the largest pipe load resistance, large flow high lift pump double volute design of the runner, radial force is small, dynamic deflection is small, the pump running smoothly, pump casing corrosion quantity is big, and have a replaceable wear ring, maximize the corrosion resistance of the pump and prolong the service life of pump;

5, pump shaft rigidity design, choose heavy cylindrical roller and double angular contact ball bearing in pairs, can bear radial load and axial load, the pump shaft overall strengthen rigidity, impeller dynamic balance test and calibration at the same time, the pump running, low noise, small vibration of shaft seal and bearing life is very good;

6, dry structure design, impeller and nuts and sleeves on the shaft, impeller nut and impeller, are seal between the impeller and shaft sleeve, under the condition of normal use, pump shaft do not contact with the medium, is not subject to corrosion medium, further improve the safety and reliability of the pump operation;

- Q: What is the minimum continuous flow of a pump?

- Quality solutionsMinimum flow of pump, minimum continuous flow of pumpIn order to ensure the proper use of the pump and the normal operation of the pump manufacturer will indicate the minimum pump in the sample of the continuous operation flow, the correct selection or use to warn or instruct users. According to the provisions of the API standard, the minimum continuous flow into the minimum continuous stable flow and continuous flow. Most small thermal limit(1) the minimum continuous stable flow.API standard specifies the minimum continuous stable flow refers to the vibration limit does not exceed the standard set by the pump can work normally. The minimum flow pump at small flow rate, there will be noise and vibration increase, API of this provision is to ensure that the service life of the pump, avoid due to improper operation of the pump caused by the adverse effects.

- Q: What are the causes of pump shock?

- Troubleshooting cause1. bearing damage, replace new bearings2., coupling pin, bolt damage, rubber column or metal bolt wear, change

- Q: How many kinds of pumps are available and the operating principles of various pumps?

- There are many kinds. See what divides.According to the working principle can be divided into: the power type pump, also called pump or impeller vane pump, depending on the dynamic effect of the rotation of the impeller on the liquid, the continuous energy transfer to the liquid, the liquid kinetic energy (mainly) and the pressure will increase, then converting kinetic energy into pressure energy through the discharge chamber, and can be divided into centrifugal pump, axial flow pump, partial flow pump and vortex pump etc..

- Q: Why should I pump the pump before starting the centrifugal pump?

- 1., if it is backward flow, it is not pumping;2., if the pump is installed underwater (such as submersible sewage pump), it is not pumping;3. pump is for installation in the form of suction. If no diversion irrigation pump, then the pump is full of air quality, air density is less than water, the pump will not be inside the gas out, the pump pressure will not be far less than the atmospheric pressure, the water will not be pressed into the pump to pump through irrigation formed inside the closed environment, the pump will start water out will cause local vacuum, entrance external water pressure into the pump is in inside and outside differential pressure, complete water movement. (vacuum water diversion is directly through the vacuum pump pumping the air in the pump, resulting in internal and external pressure difference, the external water pressure in the internal and external pressure is press into the inlet of the pump. The principle is the same as the pump. A standard atmosphere of =10m water column.)

- Q: What's the meaning of the pump head in the water pump, please advise, thank you

- In general, the pump removes the motor, and all the fittings are part of the pump head.A pump is a machine that transports liquids or pumps liquids.

- Q: Rules for operation of centrifugal pumps

- 3, start the pump, wait until the speed reaches the normal speed, slowly open the outlet valve, observe the ammeter at the same time, and control the current in the rated current range of the motor.4, the operation requires smooth operation of water pumps, no abnormal noise, no pressure fluctuations. The abnormal situation should be stopped in time.

- Q: What is the difference between centrifugal pump and rotary vane pump? What are the distinctive characteristics or principles of rotary and centrifugal? O (a _ U) O thank you!

- The vane pump can be divided into centrifugal pump, mixed flow pump and axial flow pump according to the direction of liquid flow in the impeller.Centrifugal pump is a kind of vane pump, which is the most widely used.

- Q: What do you mean by the self coupling device on the pump?

- Auto is an installation of the pump, which comprises a pedestal, self coupling frame, a guide rod and a guide rod support, the bottom fixed coupling frame, vertical installation of two guide rods can easily be brought down without installing the pump, the pump at the bottom of the pool, the outlet of the pump and the discharge tube can automatically lock, don't need to bolt connection, automatic coupling position, so as to achieve the effect of simple and convenient. When you need to repair, pump the pump up without jumping into the sink.

- Q: How to maintain and repair the booster pump of pipeline pump?

- Installation and use1. use rubber washer and bolt to connect the pump flange at both ends and the pipe flange. In order to use and maintenance convenience, in the pump inlet and outlet pipelines should be installed with a regulating valve.2. open the inlet control valve, so that water into the pump, in order to keep the cavity filled with liquid (otherwise it will damage the seal), close the outlet valve.3. turn on the power and make sure the correct turn.4. make sure the pump starts and runs after turning.5. adjust the opening of the outlet valve so that the pump runs near the design point, depending on the rated flow and lift of the pump. [for this reason, it is better to place a pressure gauge near the outlet flange). Note: this pump is strictly prohibited to run without water, so as not to damage the seal.

- Q: No negative pressure water supply equipment, both the main pump and auxiliary pump, power is not the same, how to choose the control cabinet?

- Non negative pressure variable frequency water supply means no negative pressure superposed water supply equipment. When running, it is connected directly to the water supply pipe. Always test the pressure of tap water pipe network and water supply pipe network pressure control system, when the water pressure is lower than the pressure required by the user, the frequency conversion device based on water automatically control the pump speed through the steady flow compensator of water balance, maintain a constant pressure water supply. In the multi pump system, the control system can automatically dispatch the water pump according to the water consumption. It can balance the working time of the pump and ensure the pressure of the water supply. When the water supply pressure satisfy the required pressure, the system automatically stops the pump by the external water supply pipe network directly. CJWFG-DYG non negative pressure superposed water supply system:

Send your message to us

KCZ series standard chemical process pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords