K1 Class Chemical Cross-linkable LSZH High Flame Retardant Polyolefin for Nuclear Power Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyolefin:

(1) competitive price

(2) 30 years of experience

(3) stable quality

(4) customized product

Polyolefin:

1. Applications and cable specifications:

Type | Product | Application and cable specification |

HL112-1 | K1 class chemical cross-linkable low smoke halogen free high flame retardant EPDM rubber insulating compound for nuclear power cables | 1E grade K1 class chemical cross-linkable flame retardant EPDM rubber insulation of nuclear power cables |

HL113-1 | K1 class chemical cross-linkable low smoke halogen free high flame retardant POE rubber insulating compound for nuclear power cables | 1E grade K1 class chemical cross-linkable flame retardant rubber insulation of nuclear power cables |

HL113-7 | K1 class chemical cross-linkable low smoke halogen free high flame retardant POE filling compound for nuclear power cables | 1E grade K1 class chemical cross-linkable high flame retardant filling compound of nuclear power cables |

HL113-2 | K1 class chemical cross-linkable low smoke halogen free high flame retardant POE rubber jacket compound for nuclear power cables | 1E grade K1 class chemical cross-linkable high flame retardant rubber jacket of nuclear power cables |

HF112-1 | K1 class irradiation cross-linkable low smoke halogen free high flame retardant EPDM rubber insulating compound for nuclear power cables | 1E grade K1 class irradiation cross-linkable flame retardant EPDM rubber insulation of nuclear power cables |

2. Description:

Low smoke halogen free flame retardant POE compound for nuclear power grade 1E class K1 cable, based on EPDM rubber and POE resin, is produced and pelletized by special technology, adding special modifier, halogen-free flame retardant, anti-oxidant, crosslinking sensitizer and other special additives.

3. Processing:

The following temperature(°C) profile of extruder is recommended:

| Type | Processing Equipment | Compression ratio | L/D | Processing temp. °C | Recommended vulcanize temp. | |||||

| Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die | |||||

| HL112-1 | Common rubber extruder | 1.1:1~1.5:1 | 15:1~20:1 | 60-110 | 160-200 °C | |||||

| HL113-1 | ||||||||||

| HL113-7 | ||||||||||

| HL113-2 | ||||||||||

| HF112-1 | 50 | 90 | 110 | 115 | 120 | 120 | ||||

4. Storage and transport:

Packing: 25kg/bag, PE membrane inside bag and craft outside bag.

Avoiding in direct sunlight and weathering.

Storage place should be clean, cool, dry and ventilated.

5. Properties:

| Item | Unit | HL112-1 | HL113-1 | HL113-7 | HL113-2 | HF112-1 |

| Standard | Standard | Standard | Standard | Standard | ||

| Tensile Strength | ≥MPa | 8.5 | 8.5 | 6 | 9 | 8 |

| Elongation at Break | ≥ % | 200 | 200 | 70 | 150 | 200 |

| Thermal Aging | °C×d | 135×10 | 135×10 | — | 135×10 | 135×10 |

| Variation on TS/ EB | ≤ % | ±30/±30 | ±30/±30 | — | ±30/±30 | ±30/±30 |

| Thermal Prolongation 20N/cm2 | °C×min | 250×15 | 200×15 | — | 200×15 | 250×15 |

| Elongation Under Load | ≤ % | 175 | 175 | — | 175 | 175 |

| Permanent Deformation | ≤ % | 15 | 15 | — | 15 | 15 |

| Volume Resistivity at 20 °C | ≥Ω.m | 1.0×1015 | 1.0×1012 | — | 1.0×1012 | 1.0×1015 |

| Dielectric Strength | ≥KV/mm | 25 | 20 | — | 20 | 25 |

| Oxygen Index | ≥ % | — | 30 | 40 | 30 | — |

| Impact Brittleness Temperature | °C | -30 | -30 | -15 | -30 | -30 |

| Smoke Density Flaming | ≤ | 100 | 100 | 100 | 100 | 100 |

| Non Flaming | ≤ | 350 | 350 | 350 | 350 | 350 |

| Acidity of gases evolved (PH) | ≥ | 4.3 | 4.3 | 4.3 | 4.3 | 4.3 |

| Conductivity of gases evolved | ≤μs/cm | 10 | 10 | 10 | 10 | 10 |

| Toxicity Index | ≤ | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| Water Absorption Test | °C×h | 85×336 | 85×336 | — | 85×336 | 85×336 |

| Variation on TS/ EB | ≤ % | ±40/±40 | ±40/±40 | — | ±40/±40 | ±40/±40 |

| 20°C Dielectric Constant (50HZ) | ≤ | 2.8 | — | — | — | 2.8 |

| Dielectric Loss Angular Tangent at 20°C (50HZ) | ≤ | 0.003 | — | — | — | 0.003 |

| Ozone Resistance | No cracking | No cracking | No cracking | No cracking | No cracking | |

| Irradiation Test 3300KGy | No cracking | No cracking | No cracking | No cracking | No cracking | |

| Thermal Life | ≥years | 60 | 60 | 60 | 60 | 60 |

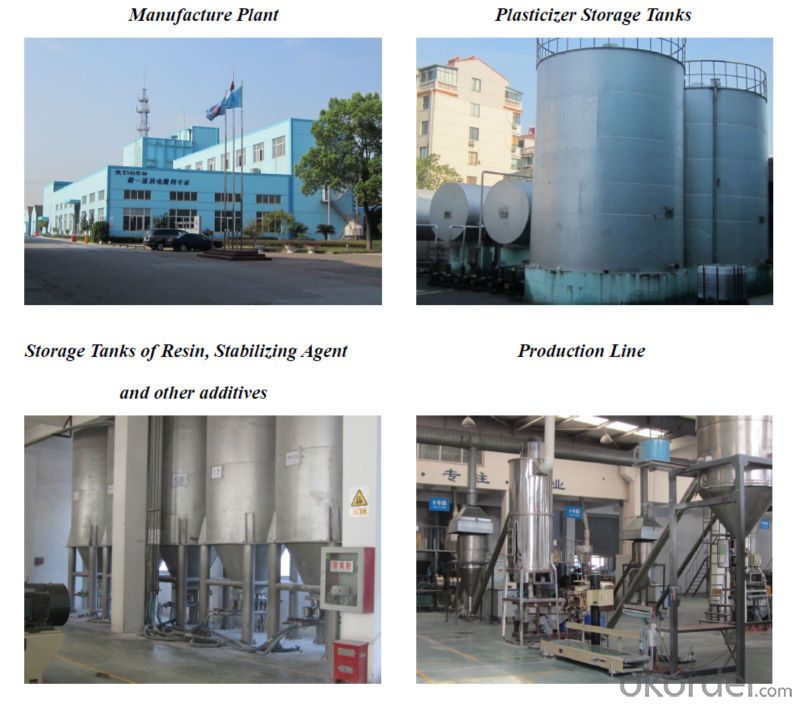

6. Company

- Q: What material is best for plastic gears?

- Gears can be made of PA, POM, etc., but PA and POM will have noise at high speeds.

- Q: Is plastic bucket and plastic bottle the same raw material?

- When the number of the triangle in the bottom of the barrel is "4", the main component of this kind of plastic barrel is low-density polyethylene, also called LDPE. Such plastic barrels of heat resistance is not strong, in case of high temperature, there will be hot melt phenomenon, will produce some of the body can not be decomposed plastic preparations, may cause breast cancer, neonatal congenital defects and other diseases.

- Q: Plastic PPT30S add what material will increase hardness?

- In general, this material will be grafted with PP-G, POE, increase the impact, plus stone powder, glass fiber, mica powder, increase hardness.

- Q: What is the difference between PA66 and PA6 plastic raw materials? Differences in price, color, performance, etc

- PA66 (polyamide 66 or nylon 66) is more widely used in the automotive industry, instrument shells, and other products that require impact resistance and high strength than PA6, PA66.

- Q: What are the plastic raw materials?

- This polymer is made up of many smaller and simpler molecules made of covalent bonds. There are many kinds of polymers, one is to change the Prajna heat to classification, it can be divided into two categories.

- Q: That kind of plastic bottle blows well

- PPEspecially the soft material, good toughness, non-toxic, high temperature resistant, often make catering appliance or other high-temperature product packaging; but the plasticity, processing difficulty, surface gloss and color processing, will be lighter, used to make disposable plastic bottles

- Q: What machines and materials are needed for the manufacture of disposable plastic cups?

- Crusher is a large size of solid materials crushed to the required size of the machine. The crusher is composed of coarse crushing, fine crushing, pneumatic conveying and so on. It achieves the purpose of crushing in the form of high-speed impact. The use of wind power as a single powder eliminates traditional screening procedures.

- Q: What kind of plastic material is used for medical instruments?

- Because most monomers and their oligomers are poisonous, medical plastics have strict restrictions on the residues of these substances;

- Q: PVC what is the difference between raw and recycled raw materials?

- Because the recycled material is a result of high temperature dissolved, it is likely to emit a pungent flavor, this odor may be harmful to humans.

- Q: What are the heavy bags in the plastic material?

- (polypropylene) English Name: Polypropylene, PP plastic concept, proportion polypropylene, also includes propylene and a small amount of ethylene copolymer. PP granular material is natural, cylindrical particles, smooth particles

Send your message to us

K1 Class Chemical Cross-linkable LSZH High Flame Retardant Polyolefin for Nuclear Power Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches