Jonhn Barnes Aluminum Coils - Sublimation Aluminum Sheet for Trailers

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Description of Sublimation Aluminium Sheet for Trailers

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

| Packing : Export wooden pallets. The bundle wegiht not exceed 2MT. Loading:by 1x20GP, 1X20GP can load about 18MT | |||||

| Standards:ASTM-B209. EN573-1, GB/T3880.1-2006 | |||||

| Quality of material: totally free from defects like white rust, oil patches, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set | |||||

| Color coated:PE/PVDF | |||||

| MOQ | 2.5tons | ||||

| Payment term: | T/T,L/C | ||||

| Delivery Time | 15 days after 30% T/T payment or receiving L/C copy | ||||

| Kind attention : Specifications can be customized as the customer’s requirements. | |||||

2. Application of Sublimation Aluminium Sheet for Trailers

Mainly used insigns, billboards, building exterior decoration, bus body, high-rise buildings and factories wall decoration, kitchen sink, lamp, fan leaves, with pieces of electronic, chemical equipment, sheet metal processing parts, deep drawing or spinning hollowware, welding parts, heat exchangers, bell surface and disk, plate, kitchenware, decorations, reflective devices, ect

3. Feature of Sublimation Aluminium Sheet for Trailers

1.High temperature resistant

2.Weathering resistant

3.Scrubbing resistant

4.Sound insulation

5.Acid or alkali proof

6. Fireproof

7.Light weight material is easy to construct and install

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

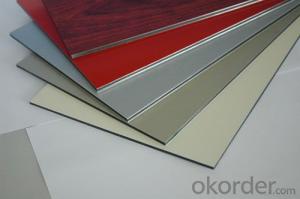

5. Image of Sublimation Aluminium Sheet for Trailers

6. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the main causes of aluminum strip rolling?

- Different thickness analysis is not the same, is curly after the thickness of the upper rib, or out of the roll can be visual?

- Q: When you are cooking fish? I ran out of aluminum foil, all I have is parchment paper on hand. Does it matter or affect the way the fish gets cooked? Just wondering what the difference is, if any.

- Aluminum foil will heat faster and retain that heat. Parchment paper will retain little heat but the fish won't stick to it when you remove it from the oven.

- Q: Can aluminum coils be used in HVAC heat exchangers?

- Yes, aluminum coils can be used in HVAC heat exchangers. Aluminum is a commonly used material in heat exchangers due to its excellent thermal conductivity, lightweight nature, and resistance to corrosion. It allows for efficient heat transfer and is often preferred over other materials like copper in certain HVAC applications.

- Q: Can aluminum coil 3003H24 replace 3A21H14?

- It is ok in some way as both of them are alumal. The hardness of 3003H24 is similar to that of 3A21H14 after hardening without annealing. Both have good corrosion resistance, plasticity and bad machinability. They cannot be used as load bearing parts even though small load is ok. They cannot be anodized.

- Q: What are the different coil edge profiles available for aluminum coils?

- Some of the different coil edge profiles available for aluminum coils include slit, deburred, rounded, and full round edges.

- Q: What is the maximum temperature that aluminum coils can withstand?

- The maximum temperature that aluminum coils can withstand depends on various factors such as the specific alloy composition, thickness, and application. Generally, aluminum coils are known for their excellent heat conductivity and resistance to high temperatures. Most commonly used aluminum alloys, such as 3003 or 5052, can withstand temperatures up to around 300-350 degrees Fahrenheit (150-175 degrees Celsius) without significant deformation or damage. However, it is important to note that exceeding this temperature range can cause the aluminum coils to lose their structural integrity, resulting in distortion, melting, or even combustion. Additionally, prolonged exposure to high temperatures can also lead to a reduction in the overall strength and performance of the aluminum coils. Therefore, it is crucial to consult the manufacturer's specifications and guidelines for the specific aluminum alloy and application in question to determine the maximum temperature limit that the coils can withstand safely.

- Q: Are aluminum coils suitable for heat sinks?

- Yes, aluminum coils are suitable for heat sinks. Aluminum is a lightweight, highly conductive material that efficiently transfers heat away from electronic components. Its excellent thermal conductivity and corrosion resistance make it a popular choice for heat sink applications.

- Q: How are aluminum coils stored in a warehouse?

- Aluminum coils are typically stored in a warehouse in a way that ensures their protection and easy accessibility. The coils are usually stacked in rows, either vertically or horizontally, depending on the available space and the weight of the coils. To prevent damage and maintain their shape, the coils are often stored on pallets or racks that provide support and stability. Additionally, the coils may be wrapped in protective materials such as shrink wrap or plastic sheets to shield them from dust, moisture, and other potential hazards. Proper labeling and organization are also crucial to facilitate inventory management and efficient retrieval. Overall, the goal of storing aluminum coils in a warehouse is to maximize space utilization, minimize the risk of damage, and ensure their readiness for shipment or further processing.

- Q: How do aluminum coils perform in high-pressure applications?

- Due to their inherent strength and durability, aluminum coils are generally well-suited for high-pressure applications. The force in a high-pressure environment necessitates materials that can endure it and maintain their structural integrity without bending or failing. Aluminum coils are renowned for their exceptional tensile strength, enabling them to handle high-pressure conditions without collapsing or buckling. Furthermore, aluminum exhibits a high resistance to corrosion, making it an ideal choice for applications where exposure to moisture or harsh chemicals is a concern. This corrosion resistance guarantees that the coils will not deteriorate or weaken over time, even under high-pressure circumstances. Additionally, aluminum coils possess excellent thermal conductivity, which allows them to efficiently transfer heat away from the high-pressure environment. This prevents overheating and maintains stable operating conditions. Moreover, the thermal conductivity of aluminum aids in rapid heat dissipation, further enhancing the overall performance of the coils in high-pressure applications. Moreover, when compared to other metals, aluminum coils are lightweight, making them easier to handle and install in high-pressure systems. The lightweight nature of aluminum also reduces the overall weight of the system, which can have advantages in terms of energy consumption and transportation costs. However, it is important to note that the specific performance of aluminum coils in high-pressure applications may vary depending on the grade and thickness of the aluminum used. Hence, selecting the appropriate aluminum alloy and gauge based on the specific requirements of the application is crucial to ensure optimal performance and longevity.

- Q: How are aluminum coils inspected for surface defects?

- To ensure the production of high-quality and defect-free aluminum coils, a variety of methods are employed to inspect for surface defects. Visual inspection is one commonly used technique, wherein trained inspectors carefully examine the entire surface of the coils for imperfections such as scratches, dents, or unevenness. This inspection takes place in optimal lighting conditions to ensure visibility and accuracy. In addition to visual inspection, more advanced techniques are utilized to detect subtle surface defects. An example of such a method is fluorescent penetrant inspection, where a fluorescent dye is applied to the coil surface. This dye seeps into any surface defects or cracks, and after a certain period of time, the excess dye is removed. The coil is then examined under ultraviolet light, which causes the dye to fluoresce, thereby making any defects easily visible. Another frequently used technique is eddy current testing, a non-destructive method that employs electromagnetic induction to identify defects like cracks or delaminations on the surface of aluminum coils. A probe is passed over the coil surface, and any variations in electrical conductivity caused by defects are detected and analyzed. Furthermore, automated systems equipped with high-resolution cameras and image-processing software can also be utilized for surface inspection. These systems capture detailed images of the coil surface, which are then analyzed by the software based on predefined criteria to identify any defects. This method ensures consistent and objective inspection results. Overall, thorough inspection procedures are implemented to detect and address any surface defects in aluminum coils before further processing or usage. These inspections are vital in maintaining product quality, adhering to industry standards, and ensuring customer satisfaction.

Send your message to us

Jonhn Barnes Aluminum Coils - Sublimation Aluminum Sheet for Trailers

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords