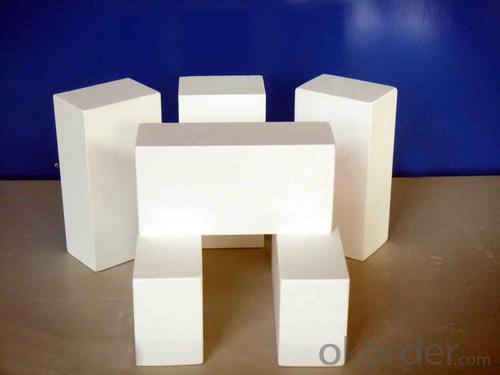

JM Series JM23 JM26 JM28 JM30 Thermal Light Weight Mullite Insulating Refractory Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Bubble Alumina Brick and Insulating Firebrick are high temperature refractory brick, max temp 1800 deg C, used in furnace kiln.

Bubble Alumina Brick and Insulating Firebrick are high temperature refractory brick.

Bubble Alumina Brick. We stock in both 2.5 & 3” sizes. We also carry double bump interlocking anchor styles. For use up to 1800C, these brick have excellent insulating properties as well as high hot strengths.

Insulating firebrick, we carry produces thirteen types of Insulating Fire Brick for use in applications from 2,000°F (1,093°C) to 3,200°F (1,760°C). Each type is formulated to meet specific thermal and physical requirements and after firing is machined to precise tolerances.

Made from high purity refractory clays and other ceramic raw materials, these insulating fire brick contain a carefully graded organic filler which is burned out during manufacture to give a uniform controlled pore structure.

Strong

The high compressive strength of bubble alumina brick allows for self-supporting structures at elevated temperatures. Insulating fire brick are compatible with dense fire brick and add strength to the whole construction.

Low Heat Storage

Lower heat storage versus dense brick means reduced fuel costs in cyclically operated heating equipment.

Application

DJM 26 Light Weight Insulating fire brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: What are the common sizes of insulating fire bricks?

- Insulating fire bricks, also known as IFBs, are widely used in various high-temperature applications due to their excellent thermal insulation properties. These bricks are available in different sizes to suit different industrial needs. The common sizes of insulating fire bricks are typically classified based on their dimensions, such as length, width, and thickness. The most common sizes range from 9" x 4.5" x 2.5" (230mm x 115mm x 65mm) to 9" x 4.5" x 3" (230mm x 115mm x 75mm). These sizes are often referred to as standard or regular size IFBs. Apart from the regular sizes, insulating fire bricks can also be found in larger or smaller dimensions to meet specific requirements. For instance, larger IFBs may measure around 12" x 6" x 4" (305mm x 152mm x 102mm), while smaller ones can be as compact as 6" x 4" x 2" (152mm x 102mm x 51mm). It is important to note that the availability of specific sizes may vary depending on the manufacturer or supplier. Some companies may offer customized sizes to cater to the unique needs of their customers. Additionally, the thickness of insulating fire bricks can also vary, with options ranging from 2" (51mm) to 4" (102mm) and beyond. When selecting the appropriate size of insulating fire bricks, it's crucial to consider factors such as the desired insulation properties, operating temperature, and the specific application requirements. Consulting with an expert or referring to manufacturer specifications can help ensure the correct size is chosen for optimal performance and efficiency.

- Q: Can insulating fire bricks be used for insulation in drying ovens?

- Insulating fire bricks are indeed suitable for insulation in drying ovens. They have been specifically engineered to offer exceptional thermal insulation, which makes them highly suitable for high-temperature applications like drying ovens. Thanks to their low thermal conductivity, these bricks are able to effectively retain heat and prevent heat loss from the oven. Furthermore, they possess a remarkable resistance to high temperatures and can endure the extreme conditions typically present in drying ovens. Moreover, their lightweight design facilitates easy installation and handling. In summary, the use of insulating fire bricks for insulation in drying ovens can enhance energy efficiency, minimize heat loss, and ensure a more consistent and controlled drying process.

- Q: Can insulating fire bricks be used in the construction of flue gas ducts?

- Yes, insulating fire bricks can be used in the construction of flue gas ducts. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation. This makes them a suitable choice for lining flue gas ducts, as they can help to reduce heat loss and improve energy efficiency. Additionally, insulating fire bricks are resistant to chemical corrosion and can withstand the corrosive effects of flue gases. However, it is important to ensure that the insulating fire bricks used are specifically designed for flue gas duct applications and meet the necessary safety and regulatory requirements. Consulting with a professional engineer or specialist in the field is recommended to ensure the correct selection and installation of insulating fire bricks in flue gas ducts.

- Q: Do insulating fire bricks require a protective coating for outdoor use?

- Yes, insulating fire bricks typically require a protective coating for outdoor use. This is because exposure to harsh weather conditions, moisture, and temperature fluctuations can potentially degrade the bricks over time. Applying a protective coating helps to enhance their durability and longevity when used outdoors.

- Q: How are insulating fire bricks installed?

- The typical process for installing insulating fire bricks involves the following steps: 1. Prepare the surface by ensuring it is clean and free of debris or loose material. This may require removing previous insulation or mortar. 2. Measure and cut the bricks to the required size, if needed, based on the area where they will be installed. A saw or specialized brick cutter can be used for this task. 3. Before applying adhesive or mortar, it is advisable to dry fit the bricks in the desired pattern to ensure proper fit and make any necessary adjustments. 4. Apply a thin layer of suitable adhesive or mortar to the surface where the bricks will be placed. It is important to use adhesive specifically designed for insulating fire bricks, which can be purchased from a hardware store or specialty supplier. 5. Carefully place each brick onto the adhesive, ensuring proper alignment and pressing firmly into place. Use a level or straight edge to check for evenness and make any necessary adjustments. 6. Fill in the gaps between the bricks with mortar once they are in place. This helps secure the bricks and provides additional insulation. Use a trowel or similar tool to spread and smooth the mortar evenly. 7. Allow the adhesive and mortar to cure according to the manufacturer's instructions. This typically involves a drying period of several hours or even days, depending on the specific product used. It is important to note that the installation process may vary depending on the type of insulating fire bricks and any additional factors, such as the presence of a furnace or kiln. If unsure about any aspect of the installation process, it is recommended to consult the manufacturer's instructions or seek professional advice.

- Q: Is it possible to recycle used insulating fire bricks?

- Yes, it is possible to recycle used insulating fire bricks. These bricks can be crushed, ground, or shredded, and then the resulting material can be used as a raw material in the production of new bricks or as an aggregate in construction materials. Recycling used insulating fire bricks helps to reduce waste and conserve resources.

- Q: Do insulating fire bricks have a low density?

- Insulating fire bricks possess a lower density in comparison to alternative brick types. Such bricks are engineered to embody a porous structure, thereby facilitating heat transfer reduction and insulation enhancement. The lightweight characteristic of these insulating fire bricks enables them to furnish efficient thermal insulation. Consequently, they prove apt for a multitude of applications wherein heat preservation and energy efficiency hold paramount significance, such as kilns, furnaces, and fireplaces.

- Q: Can insulating fire bricks be used in heat exchangers?

- Insulating fire bricks are indeed applicable for heat exchangers. Their design aims to provide exceptional thermal insulation, making them perfect for high-temperature scenarios like heat exchangers. These bricks are crafted from lightweight substances and possess minimal thermal conductivity, enabling them to effectively minimize heat loss or gain within the heat exchanger. Furthermore, insulating fire bricks exhibit remarkable resistance to thermal shock and can endure extreme temperatures, solidifying their reliability for heat exchanger applications. Ultimately, incorporating insulating fire bricks in heat exchangers can enhance energy efficiency and overall performance.

- Q: Are insulating fire bricks suitable for commercial or industrial applications?

- Insulating fire bricks are indeed suitable for commercial and industrial applications. These bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation. Due to their insulating properties, they are commonly used in various industries such as steel, cement, glass, and ceramics. In commercial applications, insulating fire bricks are often utilized in kilns, furnaces, and ovens to ensure heat retention and energy efficiency. They help to reduce heat loss, resulting in lower fuel consumption and cost savings for businesses. Additionally, their lightweight nature makes them easier to handle and install, which is advantageous in commercial settings where time is of the essence. In industrial applications, insulating fire bricks are crucial for maintaining the desired temperatures in industrial furnaces, reactors, and boilers. These bricks can withstand extremely high temperatures, making them suitable for use in harsh industrial environments. They also exhibit excellent resistance to thermal shock, meaning they can withstand rapid temperature changes without cracking or breaking. Furthermore, insulating fire bricks provide insulation against heat transfer, which helps to increase the overall efficiency of industrial processes. By reducing heat loss, they contribute to energy conservation and lower operating costs. In addition, their durability and ability to withstand the rigors of industrial operations make them a reliable choice for long-term use. Overall, insulating fire bricks are highly suitable for both commercial and industrial applications. Their exceptional thermal insulation properties, high-temperature resistance, and durability make them a preferred choice in various industries where heat retention, energy efficiency, and cost-effectiveness are paramount.

- Q: Can insulating fire bricks be used for insulation in chemical plants?

- Yes, insulating fire bricks can be used for insulation in chemical plants. These bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them suitable for insulating equipment, furnaces, and other structures in chemical plants where heat management is crucial.

Send your message to us

JM Series JM23 JM26 JM28 JM30 Thermal Light Weight Mullite Insulating Refractory Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords