Italian Q235 Steel Prop 2.0M-4.0M Standard EN1065 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

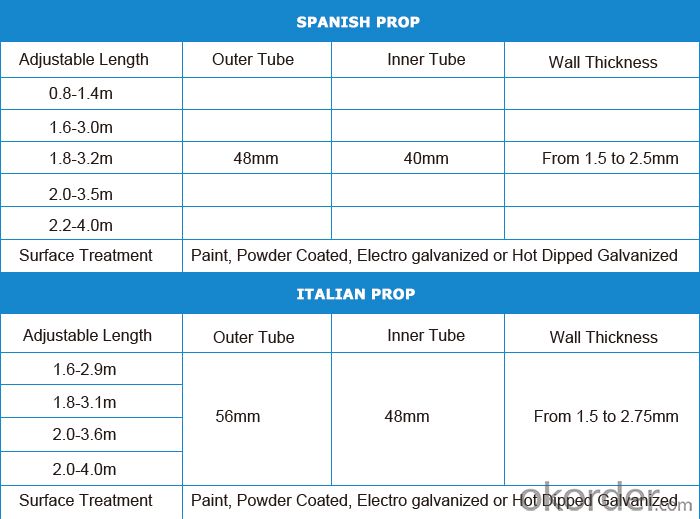

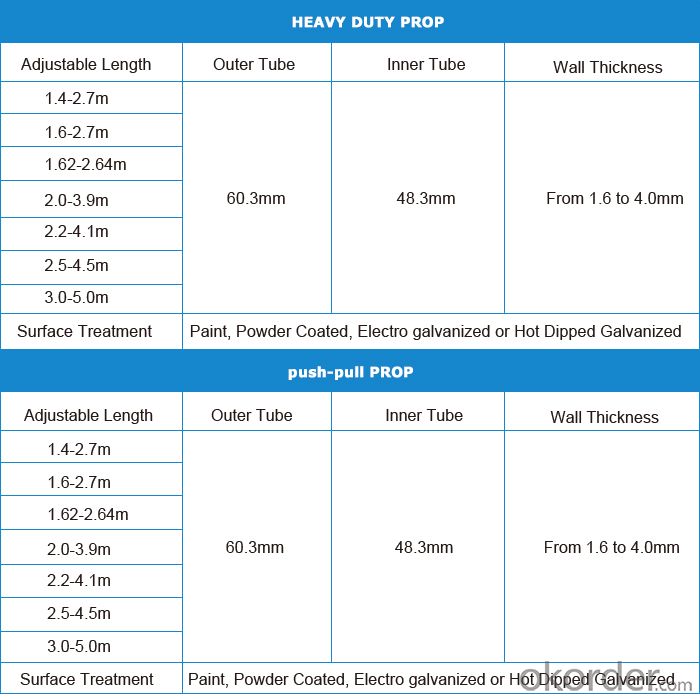

Quick Details of Italian Q235 Steel Prop 2.0M-4.0M Standard EN1065

Material :Q235 carbon steel

Surface treatment :painted/electro-galvanized/power-coating/hot dipped galvanized

Standard: EN1065

Thickness :1.6mm-3.0mm

Descriptions of Italian Q235 Steel Prop 2.0M-4.0M Standard EN1065

Our steel prop is a very Economical & practical & simple & easy installation bracing member with very high bearing capacity.

The steel props are very good vertical support suitable for various shaped slab formworks and popularly used in vertical structure support system. 4000 tons annual output.

Our steel prop used as a formwork is with very high bearing capacity.

Steel prop's vertical load capacity (within 4 meters length) can reach 10 KN.

Nuts are strictly manufactured according to national standard and with 10 tons load capacity.

Basic load capacity ≥15KN tested by national authorized organizations.

Shortening working hours & high efficiency

Firm structured props with high strength bearing capacity perfectly resisted the external shocks.

Galvanized prop surface process

Practical & Economical steel props make the buyers feel safe.

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: Where to use scaffolding in construction

- Construction height of 2m above to use scaffolding. Most of the site is the exterior, internal walls and paint.Scaffolding (scaffold) refers to the construction site for the workers to operate and solve the vertical and horizontal transport and erection of various stents. The general term of the construction industry, refers to the construction site used in the external walls, interior decoration or high level can not be directly construction. Mainly in order to work on or off the construction of the external security network and the installation of high altitude and other components, it is put on the shelf, scaffolding materials are usually made of bamboo, wood, steel or synthetic materials, etc.. Some projects also use scaffolding as a template, in addition to advertising, municipal, transportation, Luqiao, mining and other sectors are widely used.

- Q: My mom wouldn't let me get snakebites or cyberbites but she will let me get my scaffold pierced. I know people have different things for pain etc etc I know it will hurt but I want it pierced. So, to someone who has gotten it pierced or knows about it is there anything special you have to do to take care of it or is it just like the ear lobe piercing.

- it probably does hurt cuz of your cartilage just put rubbing alchahol on it and it should be okay =)

- Q: I plan to have a scaffolding or industrial piercing soon, but don't know where to go.Any suggestions and could you include the prices?x

- Cost depends on the studio. It ranges from 20 to 45 pounds for each piercing, most common price is 25 pounds for each piercing, high quality titanium or stainless steel jewelry included. The industrial is 2 piercings in one so : 25 + 25 = 50 pounds, jewelry included.

- Q: I'm a civil engineering student and we were asked to submit a paper about designing a simple scaffolding. I just want to see a sample paper so that I would know what details should I include.

- can't draw here, but it's just an x with a flat board on top in 3 dimensions.

- Q: ...and I'm not really sure what to expect. I know that everyones healing time and pain tolerence is different but just some personal storys would be nice. And before you say it I am aware that there are risks as there are risks with any piercing. so I'm 17 from London and wondering:How old do you have to be to get it done?Does anyone know a reputable place i can get it done?How much will it be?any experiences to share?

- via stretcher you advise gauge, ultimate? i've got in no way heard it suggested as a stretcher before, yet that would desire to easily be only an area slang differing style venture. besides, i think of gauges are suited or perhaps lovable in the event that they are smaller. bigger ones are too off-putting and that i might in no way do it myself. i like the belief of an commercial piercing nevertheless. i admire those. i myself % to get one sometime quickly. i've got needed one for a mutually as. i does no longer probably individually get a gauge, yet whilst that's what you sense works via all skill get one. i think of the commercial piercing is adequate on that is very own. i do no longer think of it should be accompanied via a gauge. besides, it sounds to be such as you needed the commercial piercing first, so which you may desire to start with that.

- Q: Right! I've heard from so many different people about this. Some say that you should never twist an industrial because it can damage the delicate newly healing skin cells. Others say that you must twist it to prevent the jewelry from healing attached to the skin and to be able to clean it properly.There really doesn't seem to be a definitive answer!My piercer has said not to twist it, so I haven't been, and I'm happy that the piercing is clean enough, etc. However I'm interested in whether any of you out there have found that not twisting it can damage it more than doing so.Thanks

- i twisted mine alot and the cartlidge inbetween has ripped and it hurts unbelievably loads, so i wouldnt twist it

- Q: Who has external scaffolding construction program

- Construction preparation1.1 parts1.1.1 pipe1 scaffolding steel pipe with Phi 48mm, wall thickness of 3.5mm; horizontal horizontal bar maximum length of 2200mm, the maximum length of other rods 6500mm, and the maximum quality of each steel pipe should not be greater than 25kg.2 the size and surface quality of steel pipe shall meet the following requirements:1 new steel pipe should have quality certificate, quality inspection report; steel surface should be straight and smooth, should not have cracks, scarring, stratification, dislocation, hard bend, burr, indentation and deep way;

- Q: what do you think?pain wise? i know it's going to hurt as it's a peircing (duh) but will it hurt especially as it's two thick pieces of cartilage?

- It's not going to hurt 'especially' don't worry. :) xoxox

- Q: So, 12 Days Ago I Went To Blue Banana To Get Scaffolding On My Right Ear. Everything Went Fine And They Did A Brilliant Job. I Clean It With Sea Salt Soaks 2-3 Times A Day And Use A Bit Of Tea Tree Oil After To Help Sooth. I Was Just Wondering From People Who've Experienced This Piercing How Long It Took For Yours To Stop Hurting And The Time It Took For The Swelling To Go Down (: Thank You lt;3

- It only really hurt for the first month-ish but was really tender for the first 3 months. After that, I barely noticed it was there. Goodluck :]

- Q: What is the rental price of the mobile scaffolding and accessories now? How to rent a law?

- Mobile scaffolding in general are on the basis of rent by the day

Send your message to us

Italian Q235 Steel Prop 2.0M-4.0M Standard EN1065 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords