Heavy Duty Prop 2.5M-4.5M Q235 Steel Prop Standard EN1065 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

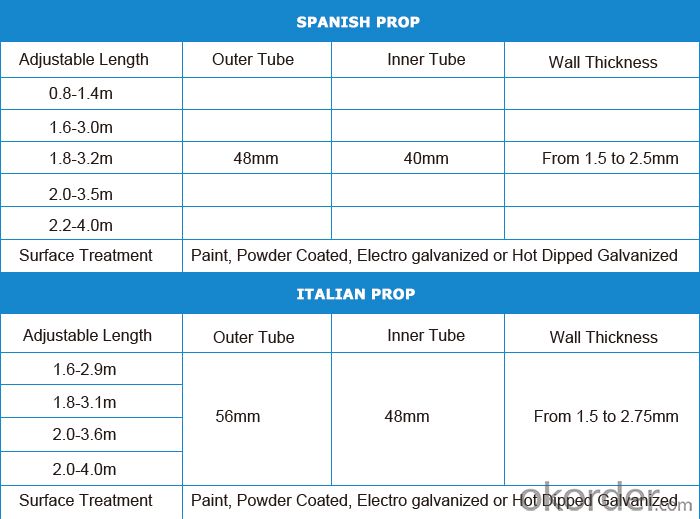

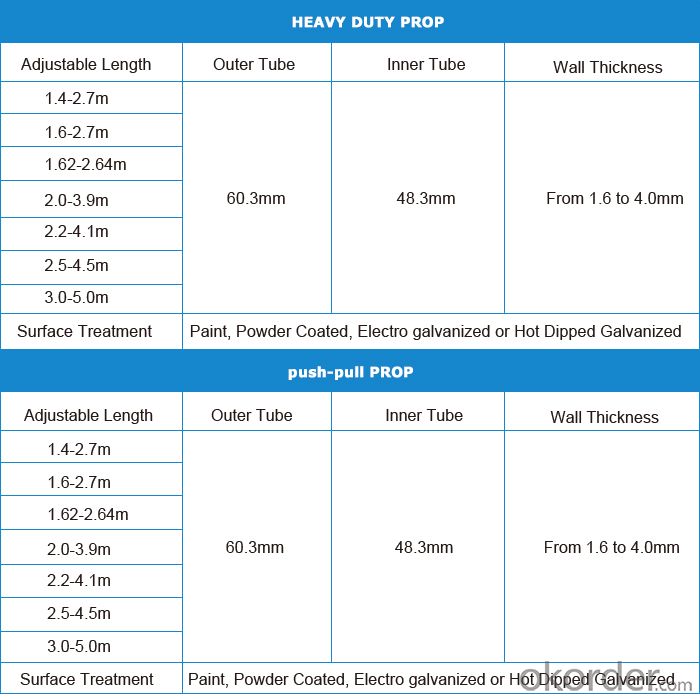

Quick Details of Heavy Duty Prop 2.5M-4.5M Q235 Steel Prop Standard EN1065

Material :Q235 carbon steel

Surface treatment :painted/electro-galvanized/power-coating/hot dipped galvanized

Standard: EN1065

Thickness :1.6mm-3.0mm

Descriptions of Heavy Duty Prop 2.5M-4.5M Q235 Steel Prop Standard EN1065

Our steel prop is a very Economical & practical & simple & easy installation bracing member with very high bearing capacity.

The steel props are very good vertical support suitable for various shaped slab formworks and popularly used in vertical structure support system. 4000 tons annual output.

Our steel prop used as a formwork is with very high bearing capacity.

Steel prop's vertical load capacity (within 4 meters length) can reach 10 KN.

Nuts are strictly manufactured according to national standard and with 10 tons load capacity.

Basic load capacity ≥15KN tested by national authorized organizations.

Shortening working hours & high efficiency

Firm structured props with high strength bearing capacity perfectly resisted the external shocks.

Galvanized prop surface process

Practical & Economical steel props make the buyers feel safe.

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: How to solve the problem of scaffold pipe repair

- Easy to move, straightening, derusting, ash removal, painting can be completed on the same machine at the same time, labor saving, labor-saving, easy to operate, can be adjusted 48mm Phi - Phi 51mm of all types of steel pipe

- Q: Cantilever scaffold technical disclosure

- First, the foot of the structure of the quality standards:1, steel pipe:(1) the steel pipe shall have the product quality certificate and inspection report with the outer diameter of 48mm and the thickness of 3.5mm of the steel pipe welded to the steel pipe of 3. Rust must be replaced, not to be used to build the frame.

- Q: What is the mobile scaffolding materials

- About looking for specific mobile scaffolding, I suggest you here to see the mobile scaffolding, mobile scaffolding here all, other parts of the mobile scaffolding, mobile scaffolding may not fully determine where is here, you can find the mobile scaffolding, mobile scaffolding because it is easy to find, but now is not the mobile scaffolding too hard to find. About looking for specific mobile scaffolding, I suggest you here to see the mobile scaffolding, mobile scaffolding here all, other parts of the mobile scaffolding, mobile scaffolding may not fully here,

- Q: i got my scaffold piercing 4 days ago and it still hurtsit usually doesn't hurt when nothing touches it, but then with the lightest touch of a finger or anything else, it hurts badly.i just cleaned it with h2Ocean and a q-tip and now it hurts really bad. :|should it not be hurting by now? or is this normal.? if its normal.. how long until it heals/stops hurting like a *****. hah

- go the the dr or you piercer

- Q: How many time was Hester Prynne on the scaffold? why was she on it each time? What about the time when pearl and dimmesdale was on it with her? HELP!!!

- She was only on it once officially but there are several appearances in the book.

- Q: i just need to know the age limit with parental permission?

- I'm pretty sure it's 16-17 with parental permission. I suggest looking up some of the shops in your area and seeing what they say. There usually isn't a set rule for it, every shop is different. Like some shops may refuse seeing, say, a 14 year old, whereas another shop might do it with the parent's permission. Then of course, once you hit 18, you can do whatever you want, lol.

- Q: by scaffolding ?

- I'm guessing it is a reference to large breasts. But I could be wrong.

- Q: i had my scaffold piercing done in the summer holidays and wen i went back to school (currently in my last year) they told me to take it out so i had to go back to the piercer. They changed the bar to two clear retainers in the holes so they wouldn't heal, now it hurts all the time and is red with a bubble on the top of my ear, any suggestions as to what i should do? :/

- regularly clean it with salty lukewarm water and cover it up with tape

- Q: Are the terms quot;nuclear matrixquot; and quot;nuclear scaffoldquot; interchangeable? I know that when we talk about DNA compaction we say that MARs on the DNA attach to the nuclear scaffold. I am wondering if the scaffold is just a specific part of the matrix??

- For most purposes, they are interchangeable terms for the same things. Some people favor one term, some the other. The ones who favor matrix over scaffold or vice versa may have some argument as to why it is better or a difference but in general people use them interchangeably.

- Q: Specific requirements, the civil code is what ah! Thank you very much, I am lack of this kind of information, I hope you can tell me which of the following

- Calculation basisScaffolding input: for the template support part of the steel pipe material in accordance with the 1.5 layer of the amount of consideration: the amount of external scaffolding steel pipe in accordance with the full closed scaffolding consideration; safety net in accordance with the external scaffolding full consideration.

Send your message to us

Heavy Duty Prop 2.5M-4.5M Q235 Steel Prop Standard EN1065 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords