ISO9001/ CE Certificated Quality Roll Dryer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Description:

Specifications

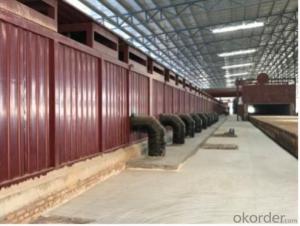

roll dryer machine

1.High efficiency dryer

2.Low noise

3.Low energy consumption

4.ISO9001:2000

Roll dryer working principle:

1.Material to be dried enters the dryer, and as the dryer rotates, the material is lifted up by a series of internal fins lining the inner wall of the dryer.

2.When the material gets high enough to roll back off the fins, it falls back down to the bottom of the dryer, passing through the hot gas stream as it falls.

3.This gas stream can either be moving toward the discharge end from the feed end , or toward the feed end from the discharge end.

4.The gas stream can be made up of a mixture of air and combustion gases from a burner, in which case the dryer is called a direct heated dryer.

5.Alternatively, the gas stream may consist of air or another (sometimes inert) gas that is preheated.

6.When the gas stream is preheated by some means where burner combustion gases do not enter the dryer, the dryer known as an indirect-heated type.

7.Often, indirect heated dryers are used when product contamination is a concern.

Roll dryer features:

1.Air heating system is able to allow highly efficient removal of water from fresh harvested forage, and the maximum durability of dehydrated forage.

2.Non-pollution to the target materials guarantees minimal loss of their color,favor,and mutritional ingredients;

3.smoke collector working with the air heating system adopts water-recled wet-type collecting method,and ensure the exhausted gas to satify the environmental protection requirement as well as the lowest water consumption.

2.New Technology Description:

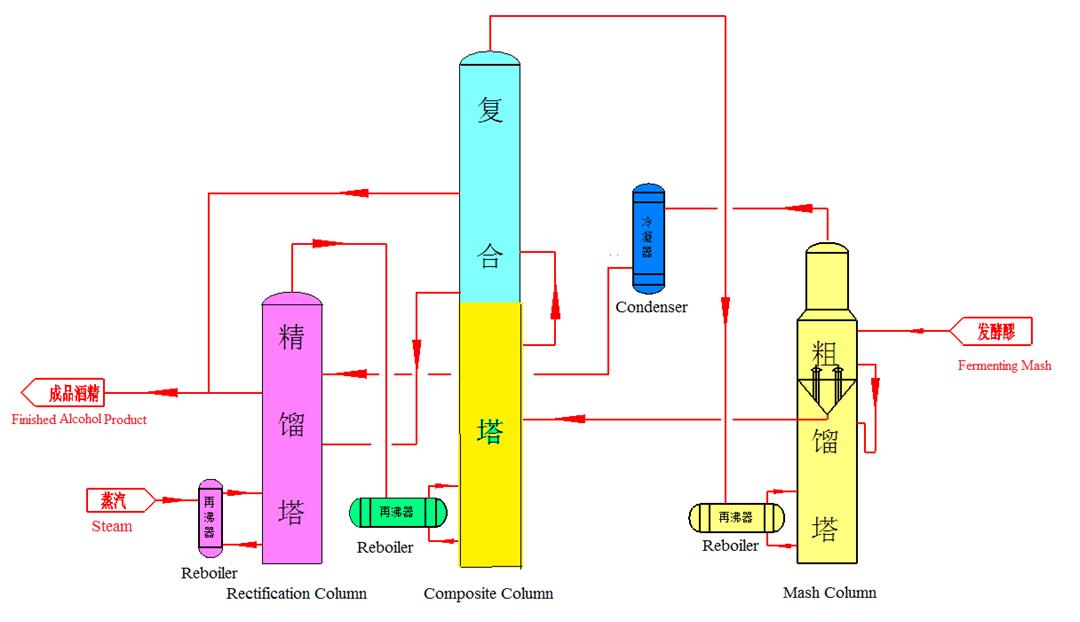

Five-Column Three-Effect Distillation Process

Our company designs and manufactures latestFive-Column Three-Effect Distillation equipment.This new process is promoted on the basis of traditional five-column differential-pressure column and mainly used for super-fine alcohol production.

The key of this process is the heating methods,the steam heats one column directly and transfers theheat to other 4 columnsto achieve three-effect thermal coupling and energy-saving effects.

In terms of electricityefficiency, it can save 50% electricity and avoid the repairing of circulating pumps and also extend the working life of there-boilers.

Energy Consumption & Quality Indicator Table Of Five-Column

Three-Effect Distillation Process for Super-fine Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗汽量Steam Consumption | t/t | 3.0 | 2.3 |

2 | 色度Colority | No. | 9.5 | 8 |

3 | 乙醇 Alcohol | %(v/v) | 95.5 | 96.5 |

4 | 硫酸试验Sulfuric Acid Test | No. | 70 | 9 |

5 | 醛(以乙醛计)Aldehyde (as acetaldehyde) | mg/l | 28 | 2 |

6 | 甲醇Methanol | mg/l | 18 | 3 |

7 | 正丙醇n-propyl alcohol | mg/l | 15 | 2 |

8 | 异丁醇+异戊醇Isobutanol+isoamylol | g/l | 27.5 | 2 |

9 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 9 |

10 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 16 |

11 | 不挥发物Nonvolatile matter | mg/l | 23 | 12 |

12 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.4 |

13 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 2 |

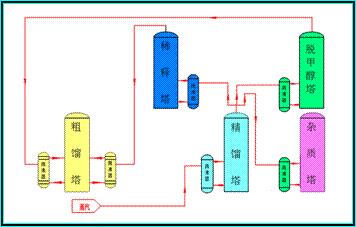

Double-Mash-Column Three-Effect Distillation Process

This process applies to the production of general-grade alcohol& fuel ethanol, and it was awarded Chinese national patent, it is the onlysuccessfulapplicationof double mash column & three-effect in the world,which produces general-grade alcohol.

This process is composed by mash column, rectification column and composite column. The composite column functions as mash column and rectification column.

The key of this process is the heating methods: the steam heats one column directly and transfers the heat to other 2 columns to achieve three-effect thermal coupling and energy-saving effects.

The advantage of this process is energy-saving;it saves over 40% steam

Energy Consumption & Quality Indicator Table for General-Grade Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗电量Electricity Consumption | kwh/t | 15 | 20 |

2 | 耗汽量Steam Consumption | t/t | 2.3 | 1.4 |

3 | 耗水量Water Consumption | t/t | 7 | 5 |

4 | 色度Colority | No. | 9.5 | 8 |

5 | 乙醇 Alcohol | %(v/v) | 95.5 | 95.5 |

6 | 硫酸试验Sulfuric Acid Test | No. | 70 | 55 |

7 | 醛Aldehyde (as acetaldehyde) | mg/l | 28 | 25 |

8 | 甲醇Methanol | mg/l | 100 | 55 |

9 | 正丙醇n-propyl alcohol | mg/l | 75 | 35 |

10 | 异丁醇+异戊醇Isobutanol+isoamylol | mg/l | 27.5 | 26 |

11 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 18 |

12 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 20 |

13 | 不挥发物Nonvolatile matter | mg/l | 23 | 21 |

14 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.5 |

15 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 3 |

3. Production Capability

1. Our company was established in the 1950s, designed and manufactured the first stainless steel distillation column in China.

2. Our company can produce 6 full sets of equipment (including crushing section, liquefying saccharification section, fermentation section, distillation section and DDGS section) in a month.

3. Among 16 production workshops,3 workshops are for mechanic manufacture, 5 workshops arefor manufacturing process, 8 workshops are for assembling & welding.

4. We own advanced machining equipment and product testing equipment.

4. Designed capability

1). We own Design License of Special Equipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class; Design License of Special Equipment GC Class.

2).Our company achieves more than 20 patent certificates on distillation, DDGS, and other fields.

3). Our company owns ASME certification, ISO 9001 Quality System Certification, ISO 14001 Environmental Management System Certification & GB/T28001 Occupational Health and Safety Management System Certification

1).Our company can provide a sophisticated product after-sale service and can ensure the implementation, maintenance and commission of projects.

2). We can reach the project site after receiving the user’s notification.

6.Package & Transport

Our company can package the products according to enterprise export standard, and use container or bulk transport.

- Q: What is the best drying equipment?

- The machine will be part of the fan by the air, through the early, middle and high efficiency filter. To 100,000 purification, the steam heat exchanger, so that the air temperature to a certain temperature

- Q: The working principle of belt dryer

- For the material temperature does not exceed 60oC requirements, can be used about 80oC dry gas. Multi-stage combination can better play the performance of belt dryer, and dry more uniform.

- Q: What are the basic types of common drying equipment?

- (2) Belt Dryer Belt Dryer consists of several independent unit segments. Each unit section includes a circulating fan, a heating device, a separate or common fresh air extraction system and an exhaust gas extraction system. On the drying medium quantity, temperature, humidity and exhaust gas circulation operating parameters, can be independently controlled, so as to ensure the reliability of working with dry and operating conditions optimization.

- Q: What are the common types of dryers?

- The tank flows into the chute of the drum dryer, and the drying drum is rotated at the specified speed by the drive.

- Q: What are the common drying methods?

- Is the use of moisture to remove gas, liquid, solid material in a small amount of water, due to moisture dehumidifier dehumidification capacity is limited, only used to remove trace moisture in the material, so the production of very little.

- Q: How to solve the dryer a series of failures

- If the dew point reading is normal after the dry machine is replaced, the dew point rises rapidly after the end of the drying cycle of the dryer, indicating that the ambient air may enter the closed gas path, causing the dryer to absorb prematurely. Another possibility is that the dryer is not completely regenerated or contaminated. If the dew point reading and reflow air dew point readings are close, it indicates that the regenerative gas path is completely failing or the desiccant is seriously polluted.

- Q: How to choose the right drying equipment and drying technology

- For non-hygroscopic materials, the moisture present in any environment remains on the surface and becomes "surface moisture" and is easily removed.

- Q: What are the types of drying equipment?

- he equipment used for the drying operation. Many types. According to the operating pressure can be divided into atmospheric pressure and pressure (vacuum dryer also known as vacuum dryer). According to the operation method can be divided into intermittent and continuous. According to the drying medium can be divided into air, flue gas or other drying medium. According to the movement (material movement and drying medium flow) can be divided into parallel, countercurrent and cross flow.

- Q: What are the characteristics of the drum dryer?

- conventional direct heating rotary drum dryer conventional direct heating rotary drum dryer in the dry material and hot air Direct contact with the way of convection heat drying in accordance with the direction of flow between the hot air and material, divided into parallel and countercurrent.

- Q: What is a combination of drying equipment?

- In this way, the drying rate can be increased, and a drying apparatus having a small volume and a high thermal efficiency can be obtained.

Send your message to us

ISO9001/ CE Certificated Quality Roll Dryer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords