Dry Roasting Equipment---Tunnel Roasting Kiln---Straight Tunnel Kiln---Assembly Type Tunnel Kiln

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 50 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

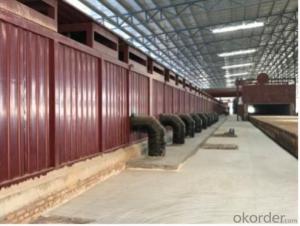

Tunnel roasting kiln can be divided into straight tunnel kiln (with kiln car) and mobile rotary tunnel kiln (without kiln car). Straight tunnel kilns can be further divided into masonry tunnel kilns and prefabricated tunnel kilns in terms of construction methods. The mobile rotary tunnel kiln belongs to the assembled tunnel kiln.

Straight Tunnel Kiln:

(1) Main products: sintered bricks, common bricks, porous bricks, hollow bricks/blocks, roof tiles, hollow wall panels.

(2) According to the different output, the inner width of the tunnel kiln is divided into the following types:

① the inner width is 3.6 and 3.7 meters, suitable for daily output of 150,000-200,000 blocks, and annual output of 50-66 million (common bricks)

② the inner width is 4.6 and 4.8 meters, suitable for daily output of 210,000-250,000 blocks, and annual output of 69-82 million (common bricks)

③ the inner width is 5.4 and 5.6 meters, suitable for daily production of 260,000-300,000 pieces, and annual output of 85-100 million (common bricks)

④ the inner width is 6.9 and 7.2 meters, suitable for daily output of 310,000-400,000 blocks, and annual output of 102-132 million (common bricks)

⑤ the inner width is 9.2 and 9.4 meters, suitable for daily output of 600,000-620,000 pieces, and annual output of 165-200 million (common bricks)

(3) Kiln Body Structure

Assembly Type Tunnel Kiln

The kiln wall and kiln roof are factory processed into different units and spliced on site. The structural form of kiln wall is non-sintered clay refractory concrete wall panel + high-strength heat-resistant stainless-steel component + refractory fiber module + steel structure + enclosure pressure steel plate. The structural form often used on the kiln roof: light mullite plate + high-strength heat-resistant stainless-steel components + aluminum silicate refractory fiber blanket + steel structure.

(4) Firing temperature: 950-1050℃

(5) Firing cycle: 26-40h

(6) Length of tunnel kiln: 110-170m

(7) Length and size of kiln car: It is determined according to the size of the billet stack and the internal and external combustion method. The length and size of the commonly used kiln car are: 3600mm, 3900mm, 4100mm, 4200mm, 4350mm, 4800mm, etc.

(8) Firing method: all internal combustion roasting; all external combustion roasting; combined internal and external combustion roasting.

(9) The roasting kiln is often equipped with a smoke exhaust system, a combustion system, a waste heat system, a backburning system, a cooling system, and a bottom pressure balance system. Each system consists of fans, pipes and regulating valves. The kiln has a large section, high output, small temperature difference between sections, and good thermal insulation performance. Computer automatic monitoring and control system to ensure the stability of thermal parameters and roasting quality.

- Q: What is the best drying equipment?

- In the traditional horizontal fan-type dryer, the air flow only in the material surface flow, the drawback is the low heat transfer coefficient, poor heat utilization, material drying time is long.

- Q: The working principle of belt dryer

- Drying process is a hot air flow through the material layer, complete the process of heat and mass transfer, the upper cavity connected by the duct and the fan inlet. Most of the gas circulation, part of the lower temperature of the larger moisture content of the gas as exhaust gas through the drainage tube, regulating valve, drain fan discharge. The next cycle of the unit, the fan out of the wind into the upper cavity, down through the heat exchanger heating, through the material layer into the lower chamber, the lower chamber by the side duct and return air duct connected to the fan, most of the gas circulation, Part of the discharge. Up and down the cycle unit according to user needs can be flexible equipment, the number of units can also be selected according to need.

- Q: What are the basic types of common drying equipment?

- (3) drum scraper dryer drum scraper dryer is through the rotation of the cylinder, heat conduction way, will be attached to the outer wall of the cylinder liquid material or ribbon material, a dry continuous operation of equipment The The material to be dried is passed from the upper tank into the receptacle of the drum dryer. The drying drum is driven at the specified speed by the drive.

- Q: What are the common types of dryers?

- The amount of operating parameters, can be independently controlled, so as to ensure the reliability of the work with dry and operating conditions optimization.

- Q: What are the common drying methods?

- heating and drying method

- Q: How to choose the right drying equipment and drying technology

- In the drying process of materials, different materials are not the same characteristics, drying requirements are not the same, drying methods are also different, how to choose the right drying equipment and it?

- Q: What are the types of drying equipment?

- According to the heating method, the dryer is divided into convection, conduction, radiation, dielectric and other types. Convection dryer, also known as direct dryer, is the use of hot dry media and wet material in direct contact with convection way to transfer heat, and the generated steam away; Conductive dryer also known as indirect dryer, which uses conduction The heat is transferred from the heat source through the metal wall to the wet material, and the resulting wet steam can be removed by means of reduced pressure suction, passing a small amount of purge gas or condensing it on a separately provided low

- Q: Frozen sublimation drying equipment which consists of several systems

- the control system: the control system consists of a variety of monitoring the original, an umbrella device, instrumentation and other components, a higher degree of automation control system can be set by the freeze-drying process automatically operate, while the vacuum, heating plate temperature and cooling System monitoring and alarm, record all kinds of data.

- Q: What are the characteristics of the drum dryer?

- The main body of the rotary drum dryer is a slightly tilted and rotatable drum, and the wet material is fed from one end thereof and passes through the inside of the drum and is dried in contact with the hot air or the heated wall in the cylinder. , Chemical industry, metallurgy, building materials and other industries have a wide range of applications. Rotary drum drying and other drying equipment compared to the production capacity, continuous operation and simple structure, easy operation and less trouble, low maintenance costs

- Q: What is a combination of drying equipment?

- Combination drying equipment is a combination of two or more dry forms, the main material, mainly in series, that is, when the material has been through the drying equipment, two or more drying equipment, combined dry mainly to meet a The need for a drying process.

Send your message to us

Dry Roasting Equipment---Tunnel Roasting Kiln---Straight Tunnel Kiln---Assembly Type Tunnel Kiln

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 50 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.